A self-rotating electrospinning device assisted by high-pressure airflow

An electrospinning and self-rotating technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of thick fiber diameter, low efficiency, and difficult die processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

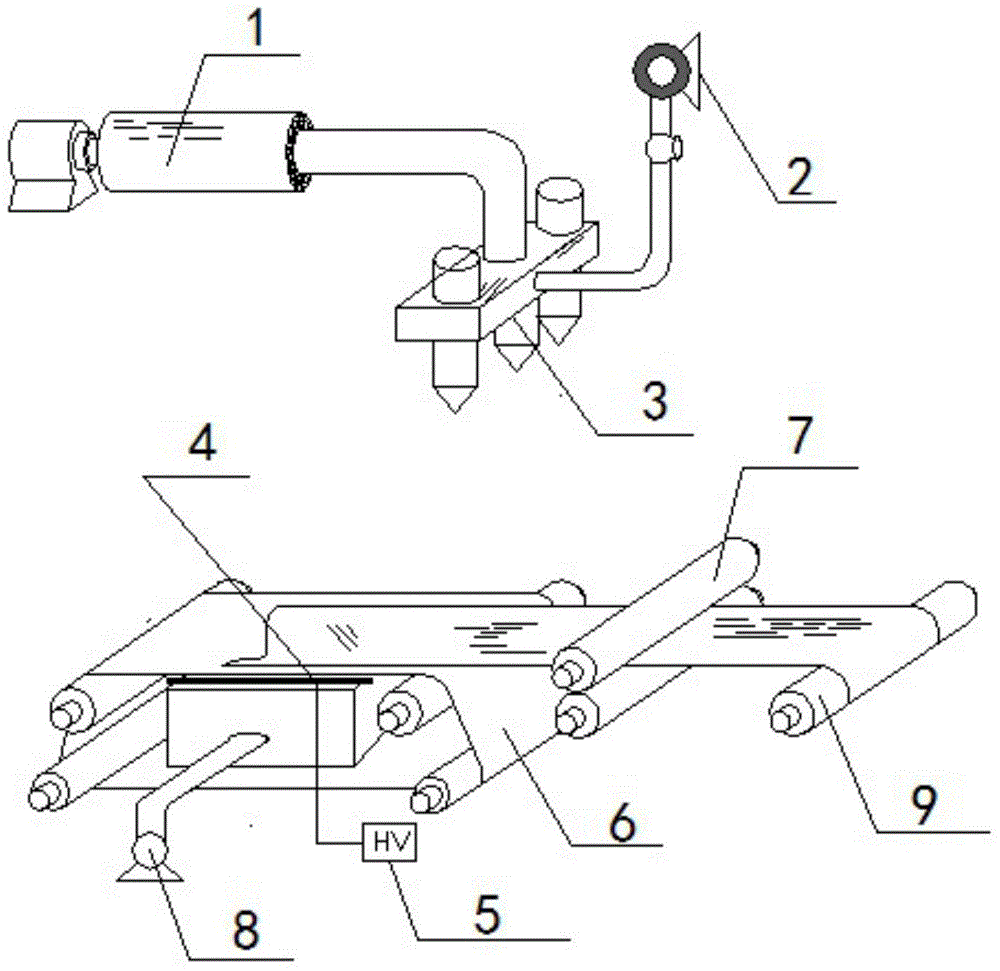

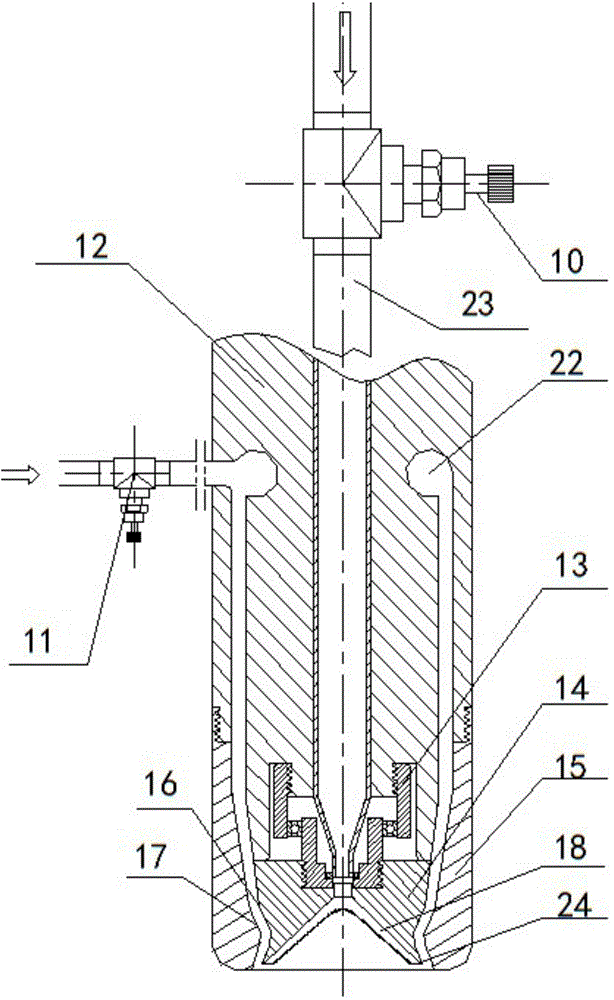

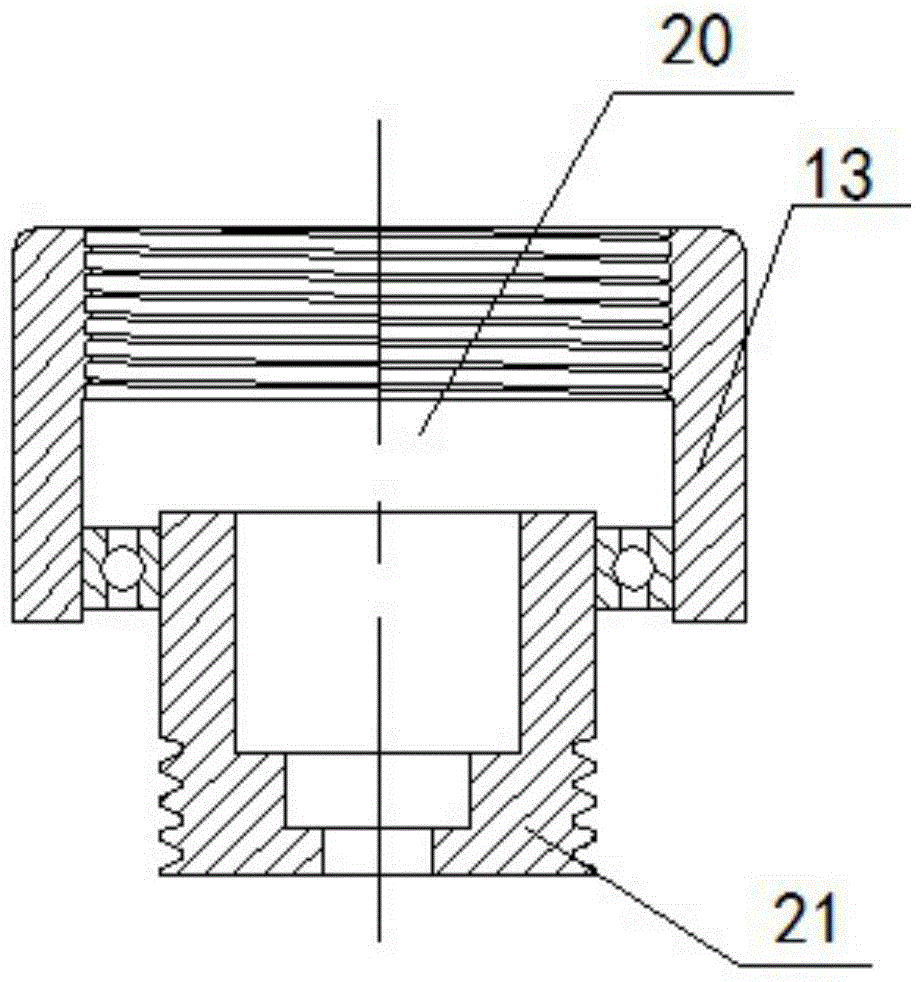

[0020] The invention provides a self-rotating electrostatic spinning device assisted by high-pressure airflow. The overall schematic diagram of the device is as figure 1 As shown, the spinning device includes a feeding device 1, an air compressor 2, a spinning nozzle 3, an electrode plate 4, a high-voltage electrostatic generator 5, a laying belt 6, a hot roller 7, an exhaust system 8 and a receiving device 9. The air compressor 2 is connected to the annular flow channel 22 through the gas flow regulating valve 11, the feeding device 1 is connected to the feeding flow channel 23 through the solution flow regulating valve 10, the mesh belt 6 is installed directly under the spinning nozzle 3, and the electrode plate 4 is close to the upper surface of the mesh belt 6 and connected to the high-voltage electrostatic generator 5. In order to facilitate the normal operation of the ventilation system 8, the electrode plate 4 adopts a mesh uniform structure, and the ventilation system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com