Method for excavating weak surrounding rock tunnel under water-rich high-ground-stress conditions

A technology with high ground stress and weak surrounding rock, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as easy collapse of surrounding rock excavation, reduction of compressive strength, intrusion into the secondary lining, etc., to improve safety and engineering quality, speed up the construction progress, and solve the effect of steel frame distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

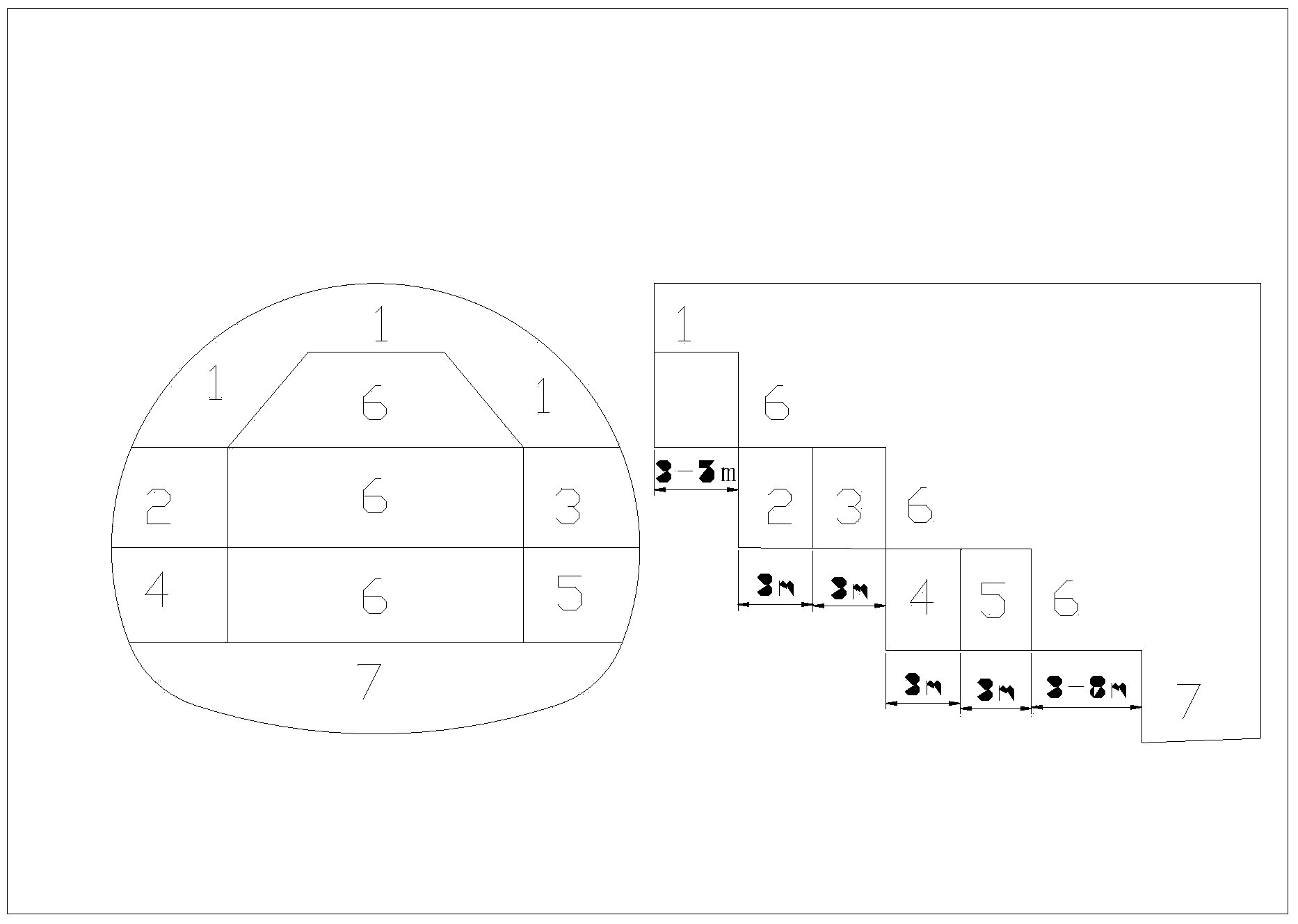

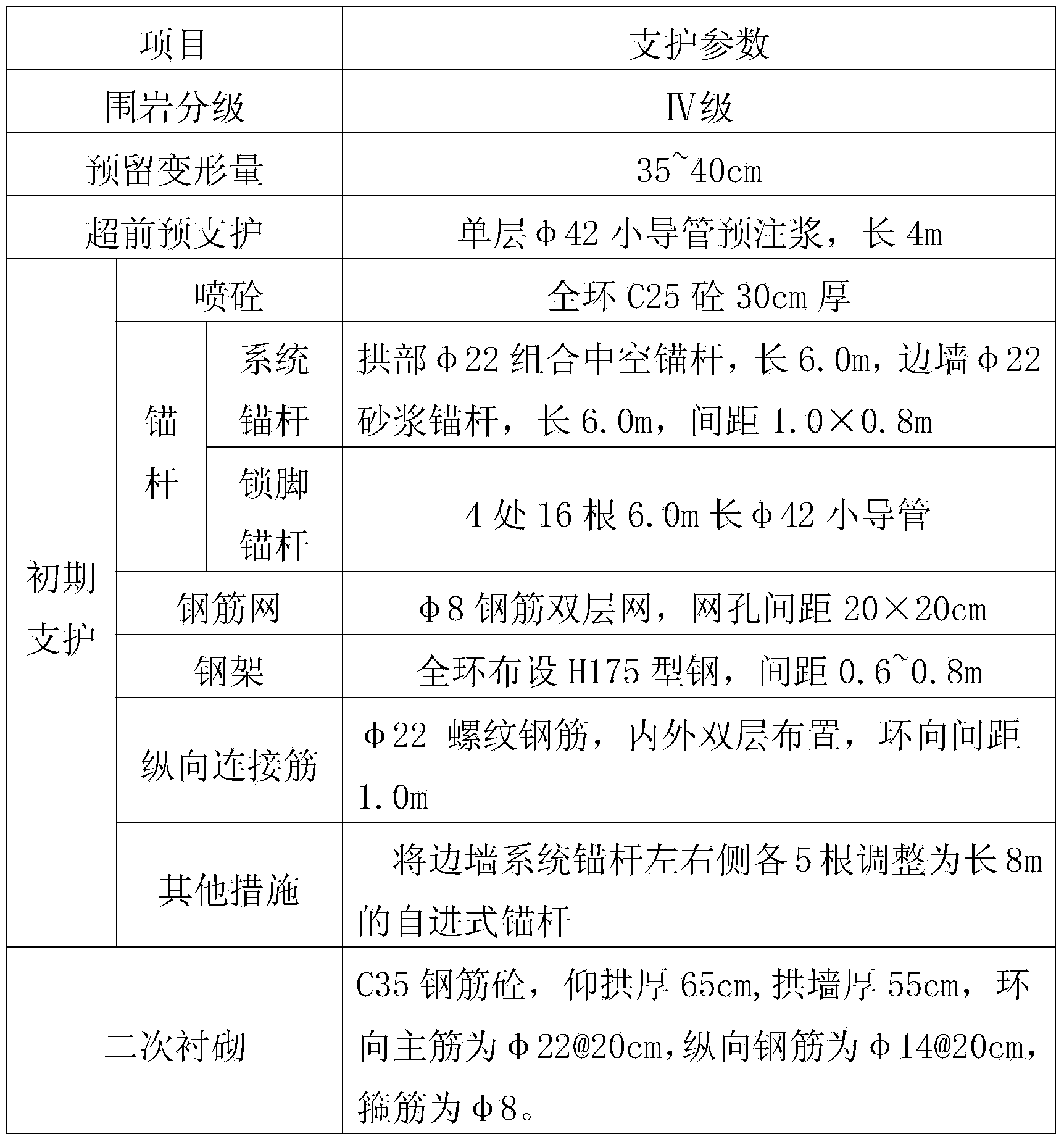

[0014] Such as figure 1 Shown: excavation method of the present invention is, before excavation of tunnel, implement ahead of time and do single-layer long 4 meters φ 42 small conduit pre-grouting, do advance support. The three-step seven-step method is used for excavation, which can reduce the disturbance of the blasting to the surrounding rock, and excavate first figure 1 For part 1 shown, after the initial support is excavated, part 2 will be excavated, and the support will be excavated in sequence according to 3, 4, 5, 6 and 7. The determination of the excavation height of the upper bench is extremely important. Although increasing the excavation height of the upper bench increases the clearance of the upper bench to a certain extent, which is beneficial to the construction operation, it will increase the deformation of the surrounding rock and increase the strength of the supporting structure. Force. After theoretical analysis and field practice, the upper step is prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com