Gas cooker dry burning preventing device with self power generation function

A self-generating, dry-burning prevention technology, applied in heating fuels, household appliances, gaseous heating fuels, etc., can solve problems such as inconvenience in use, and achieve the effects of easy maintenance, reducing pollution and avoiding hidden dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

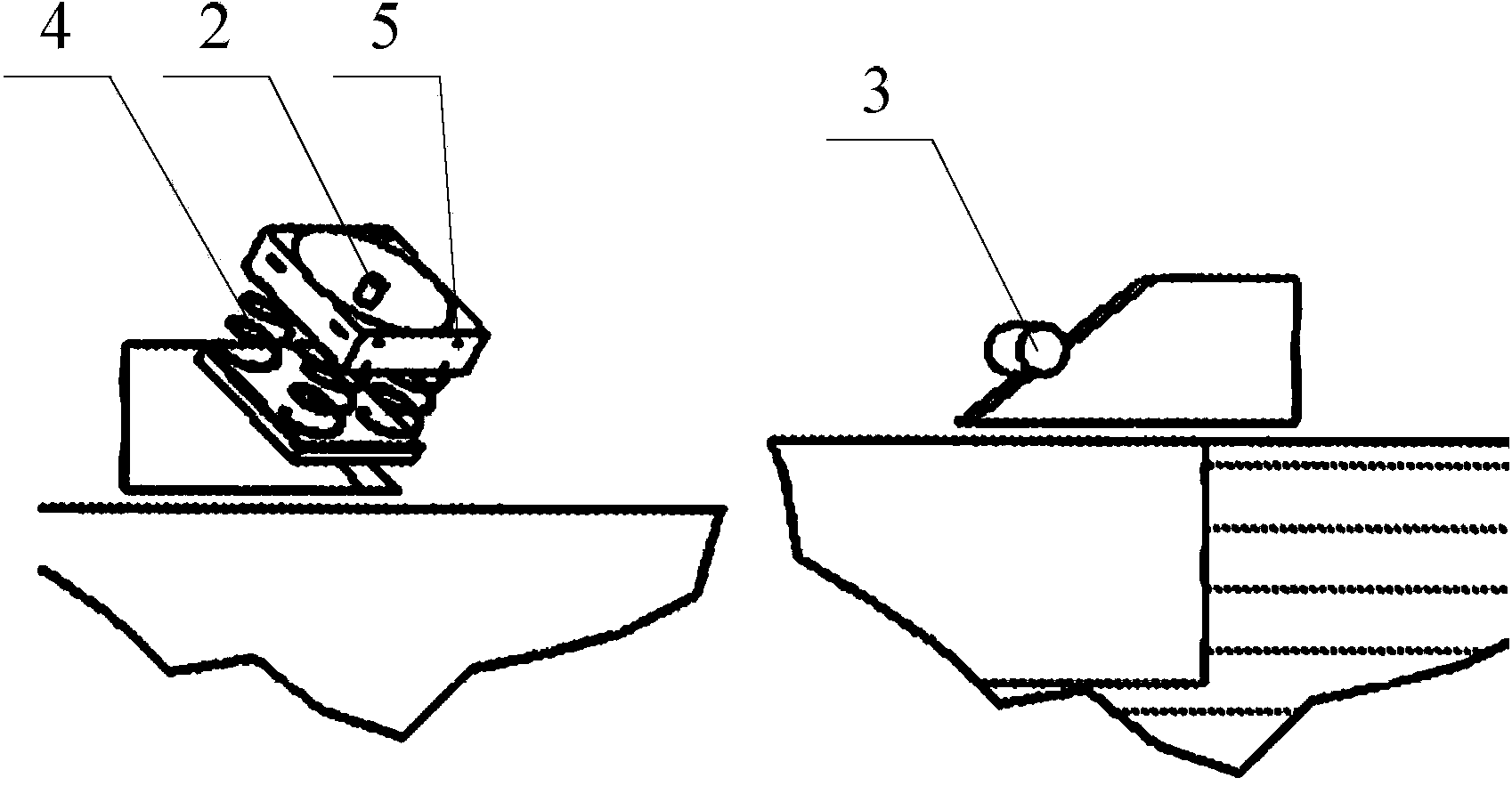

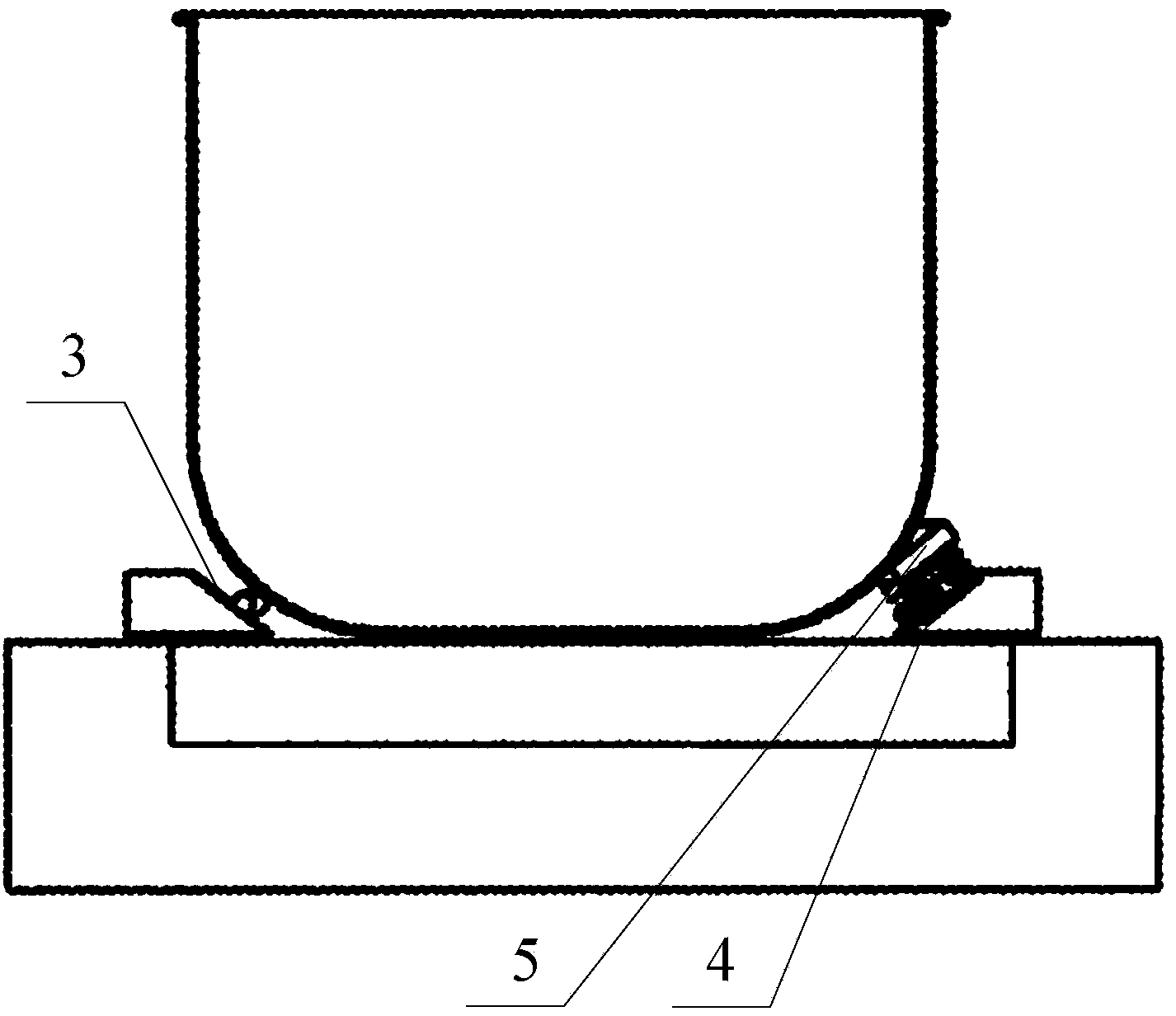

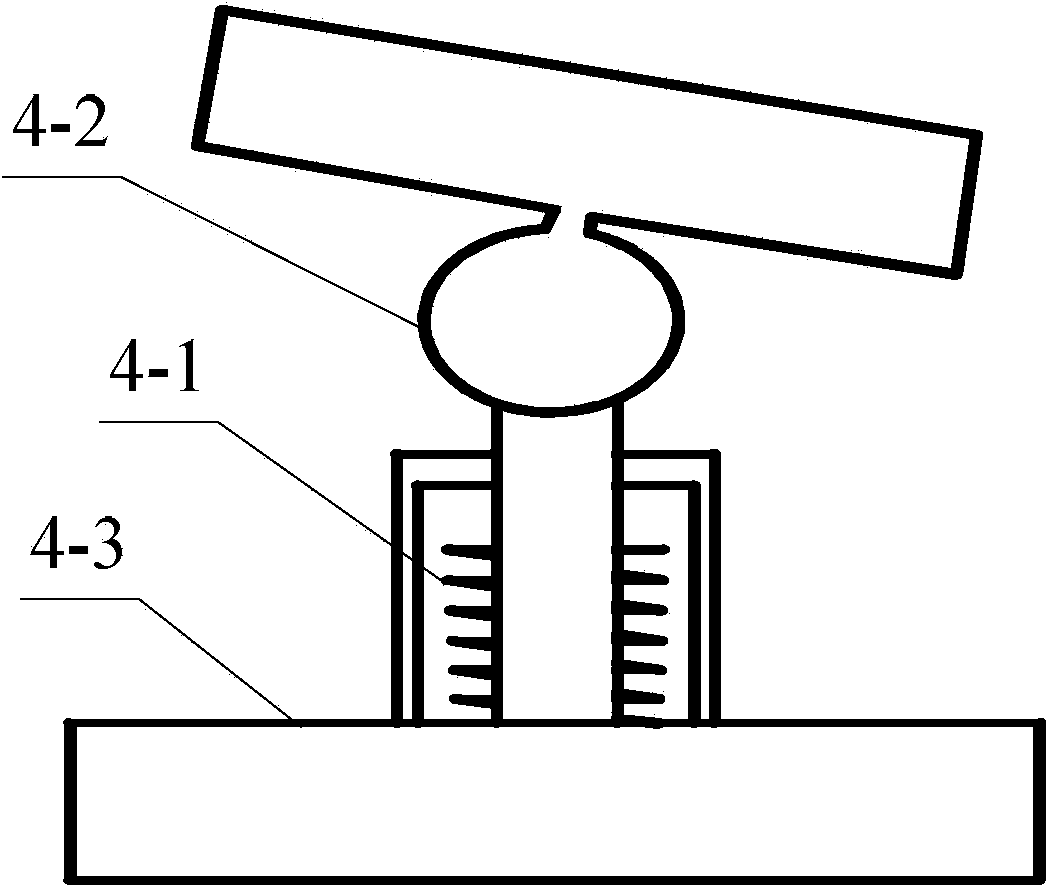

[0027] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment, the anti-dry burning device for gas cooker with self-generating function described in this embodiment, it includes a microprocessor 1, it also includes a thermocouple 2, a direct flame fuel cell group 3, a direction adjuster 4, and a thermal insulation body 5 and rechargeable battery 6,

[0028] The direct flame fuel cell group 3 is composed of a plurality of sheet-shaped direct flame fuel cell cells, and the plurality of sheet-shaped direct flame fuel cell cells are connected and fixed in series through stainless steel connectors;

[0029] The direct flame fuel cell group 3 is used to be placed in the flame of the gas cooker, the temperature measuring end of the thermocouple 2 is embedded in the heat preservation body 5, and the temperature measuring end of the thermocouple 2 is used to contact the temperature measuring point of the upper pot body of the cooker, ...

specific Embodiment approach 2

[0036] Specific implementation mode two: the following combination Figure 4 Describe this embodiment. This embodiment will further describe Embodiment 1. This embodiment also includes an alarm 7 , and the alarm signal input end of the alarm 7 is connected to the alarm signal output end of the microprocessor 1 .

[0037] The microprocessor 1 outputs an alarm signal by controlling the alarm 7, and the alarm 7 can realize the alarm by sounding a buzzer or flashing a light-emitting diode indicator light.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment further describes Embodiment 1 or 2. The thermal insulation body 5 described in this embodiment is a porous ceramic block, ceramic fiber block, silica brick, clay brick or magnesia brick.

[0039] The shape of the heat insulating body 5 can be cylindrical or cubic, and it has two functions: one is to prevent the temperature measuring end of the thermocouple 2 from contacting with the hot air flow, and the other is to increase the specific heat capacity of the thermocouple 2 and reduce the temperature signal. fluctuation.

[0040] The thermal insulation body 5 can be made of a poor conductor of heat, for example, solidified by refractory cotton plus a coagulant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com