A three-dimensional small-angle measuring device and its method for dynamically measuring three-dimensional angle variation

A measuring device and small-angle technology, which is applied in the direction of measuring device, measuring angle, adopting optical device, etc., can solve the problem that roll angle measurement cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

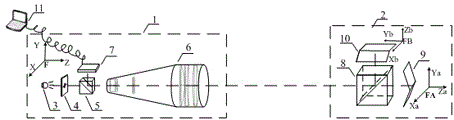

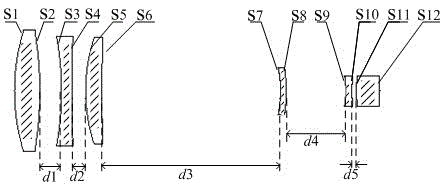

[0073] The three-dimensional small-angle measuring device of the present invention includes a transmitting / receiving device 1, a reflecting device 2 and a data processing computer 11, wherein the transmitting / receiving device and the reflecting device are respectively fixedly connected to the measurement reference and the point to be measured. The transmitting / receiving device includes an LED light source 3 , a cross-shaped aperture 4 , a beam splitting prism A5 , a measuring lens 6 and a photodetector 7 . The light emitted by the LED light source 3 passes through the cross-shaped light hole 4 and the dichroic prism A5, then is collimated by the measuring lens 6, and then enters the reflection surface of the reflection device 2, then reflects back to the measuring lens 6, and finally enters through the dichroic prism A5 to the photodetector 7; the data processing computer 11 is connected to the photodetector 7 to collect image data in real time and calculate the three-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com