Light-emitting device with high red light brightness and high reliability

A light-emitting device and a technology of a light-emitting layer, which are applied in the direction of optical elements, lighting devices, and components of lighting devices used to change the spectral characteristics of emitted light, can solve high heat, low aluminum reflectivity, red light efficiency and brightness low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

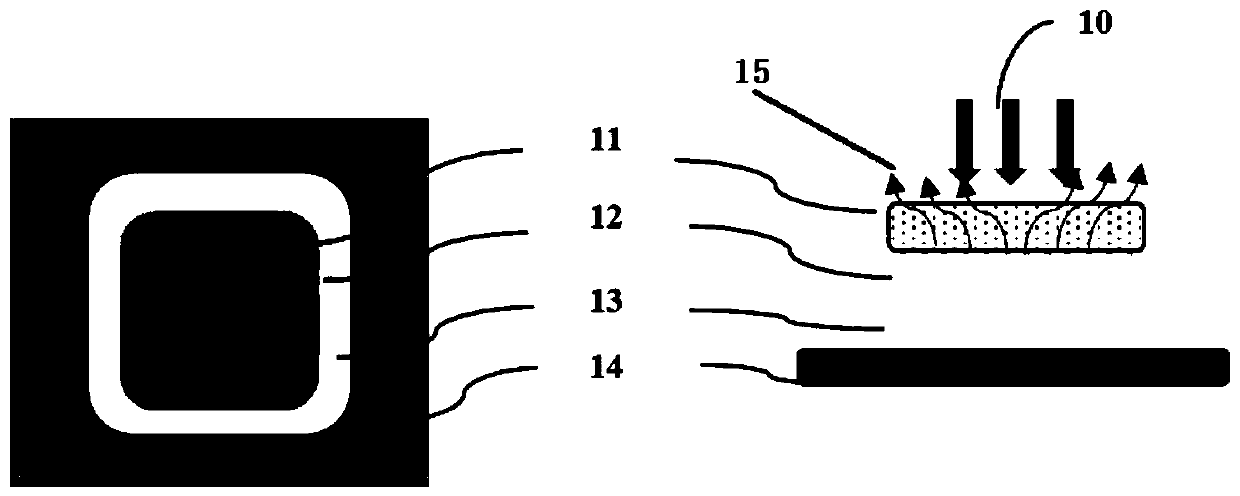

[0052] Embodiment 1 (light-emitting device with fixed red light-emitting module)

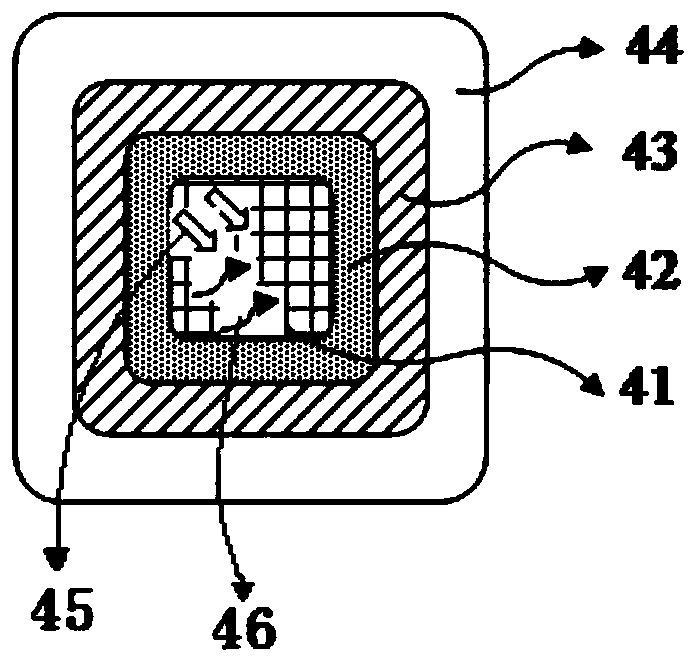

[0053] A schematic diagram of the structure of a light emitting device with a fixed red light emitting module according to Embodiment 1 of the present invention is as follows image 3 As shown, the fixed red light-emitting module of the light-emitting device is composed of a light-emitting layer 41 , a reflective layer 42 , a welding layer 43 and a heat-conducting substrate 44 . The solder layer 43 is disposed on the thermally conductive substrate 44 . The reflective layer 42 is provided on the solder layer 43 . The light emitting layer 41 is provided on the reflective layer 42 . In this embodiment, the luminescent layer 41 is specifically composed of luminescent ceramics as the luminescent part, wherein the luminescent ceramics are preferably Ce 3+ The doping concentration is 1.2mol% of Y 3 Al 5 o 12 Pure phase ceramic or Al 2 o 3 -Y 3 Al 5 o 12 Composite ceramics, or Ce 3+ The dopi...

Embodiment 2

[0056] Embodiment 2 of the present invention (rotary fluorescent color wheel)

[0057] In Embodiment 2 according to the present invention, a rotating fluorescent color wheel is provided, and its structural schematic diagram is as follows Figure 4 As shown, the rotary fluorescent color wheel includes an annular heat-conducting substrate 55, a welding layer 54, a reflective layer (including a red reflective layer 52a, a green reflective layer 52b, a blue reflective layer 52c and a yellow reflective layer 52d arranged coplanarly. ) and light emitting layers (including red light emitting layer 51a, green light emitting layer 51b, blue light emitting layer 51c and yellow light emitting layer 51d arranged coplanarly). The solder layer 54 is disposed on the thermally conductive substrate 55 . The red light reflective layer 52 a , the green light reflective layer 52 b , the blue light reflective layer 52 c and the yellow light reflective layer 52 d are respectively disposed on diffe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com