Ore sample preparation system

A sample preparation system and ore technology, which is applied in the field of mineral processing, can solve the problems of large space occupation, small processing capacity, and easy occurrence of sticking and clogging, so as to increase sample preparation volume, prevent sticking and clogging, and reduce occupied space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

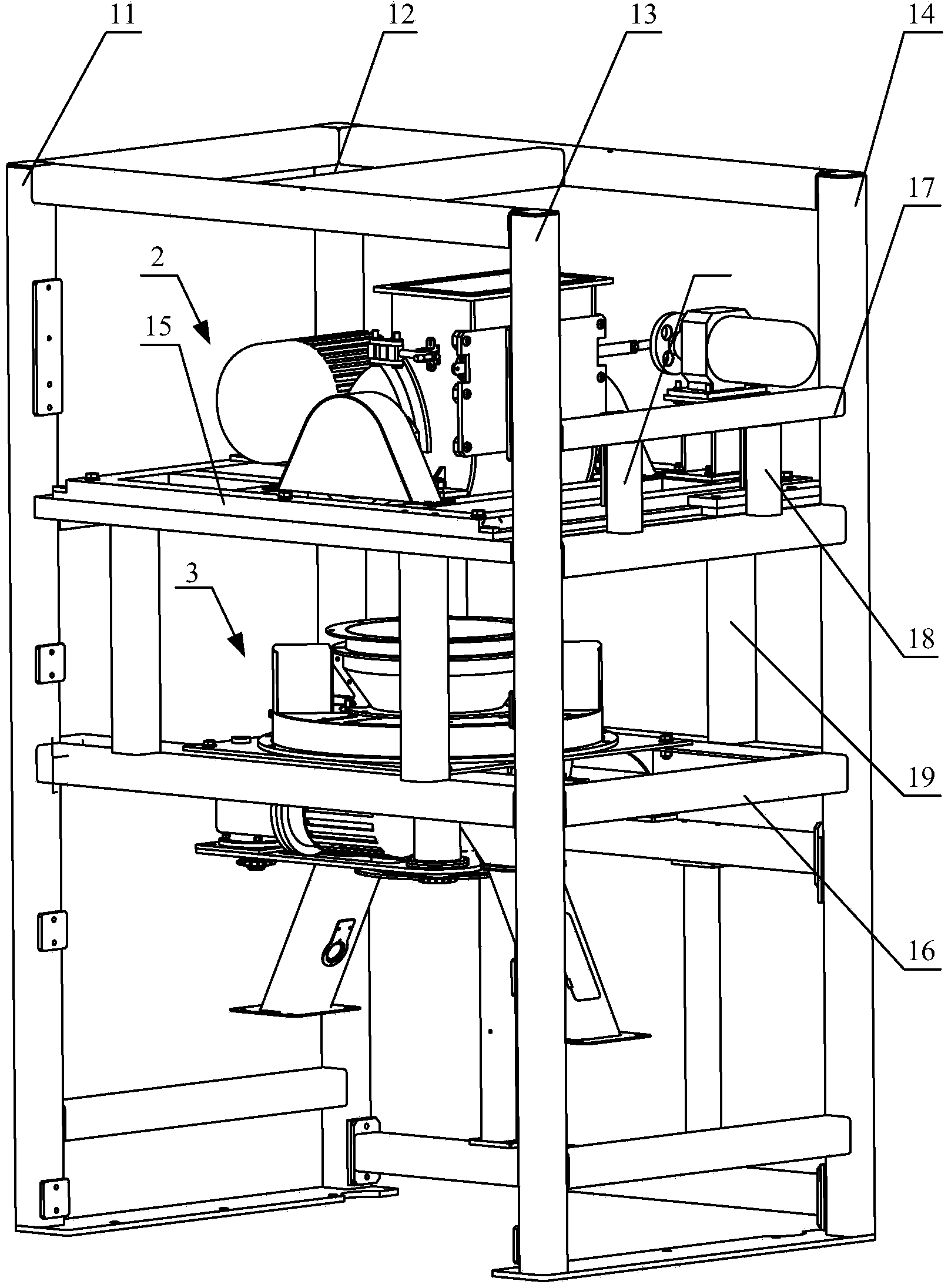

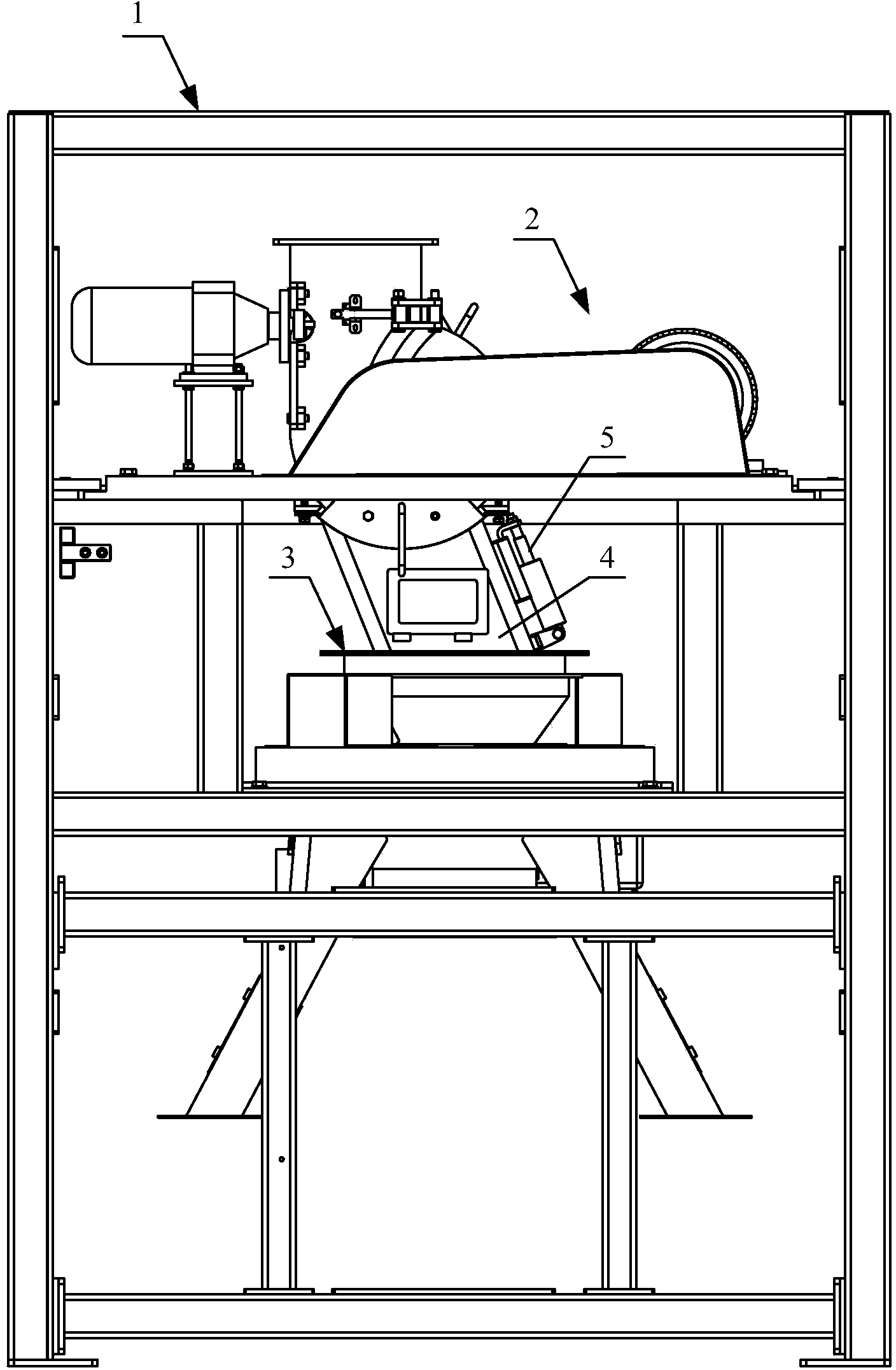

[0025] The core of the invention is to disclose an ore sample preparation system to achieve the purpose of increasing the amount of sample preparation and reducing the space occupied by equipment.

[0026] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

[0027] like figure 1 and figure 2 As shown, the ore sample preparation system includes a frame 1, a crusher 2, a chute 4 and a shrinking machine 3. Both the crusher 2 and the shrinking machine 3 are set on the frame 1, and the crusher 2 is located above the shrinking machine 3. , the discharge port of the crusher 2 communicates with the feed port of the shrinking machine 3 through the chute 4 .

[0028] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com