Ignition device for spark ignition engines

A technology of ignition device and Otto engine, which is applied in the direction of ignition circuit layout, induction energy storage device, transformer/inductance parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

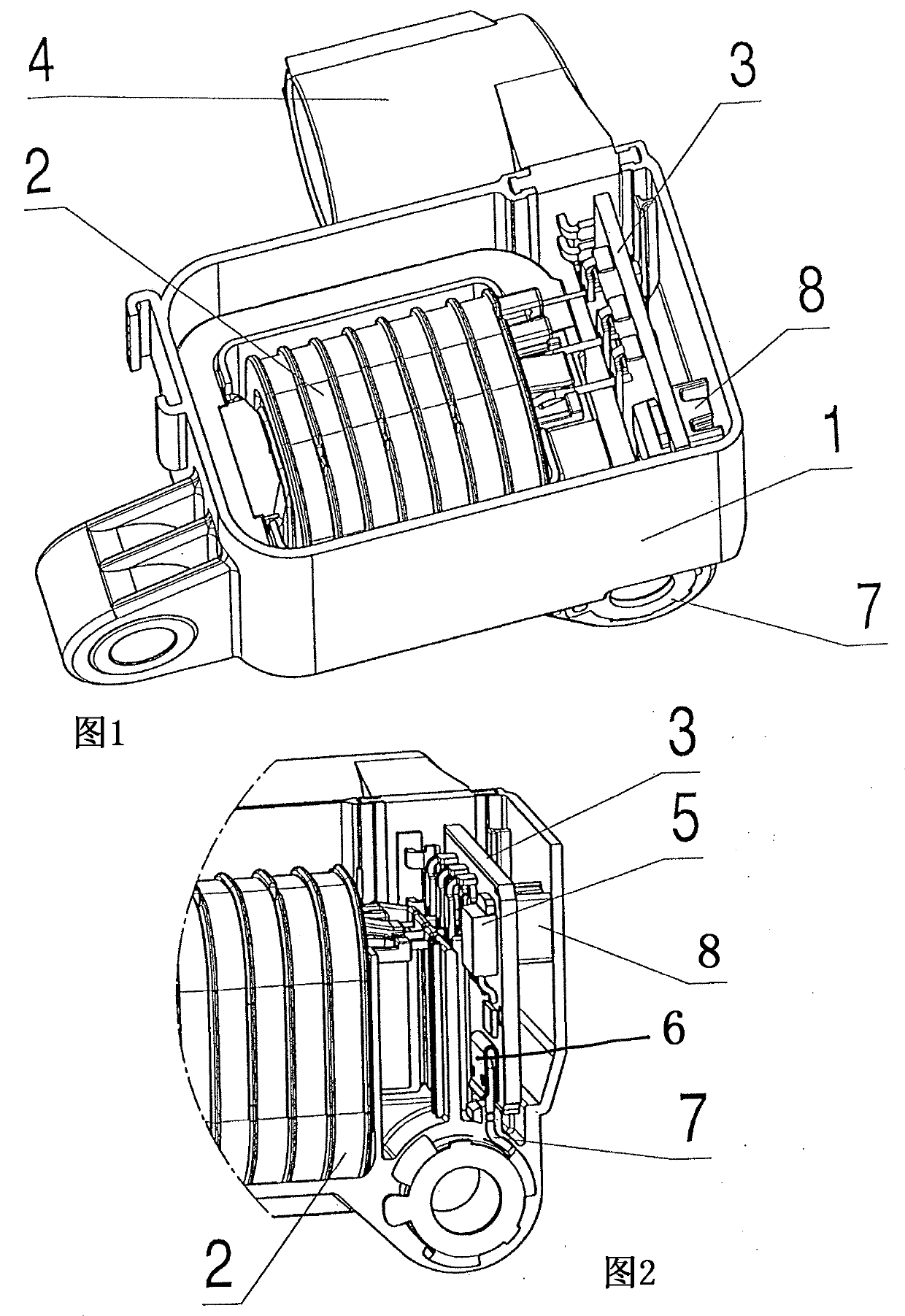

[0016] The ignition device shown has a plastic housing 1 in which is arranged an ignition coil 2 with primary and secondary windings and a printed circuit board 3 carrying a control circuit. The plastic housing 1 includes a plug connector 4 for connecting the ignition to the on-board power supply of the motor vehicle.

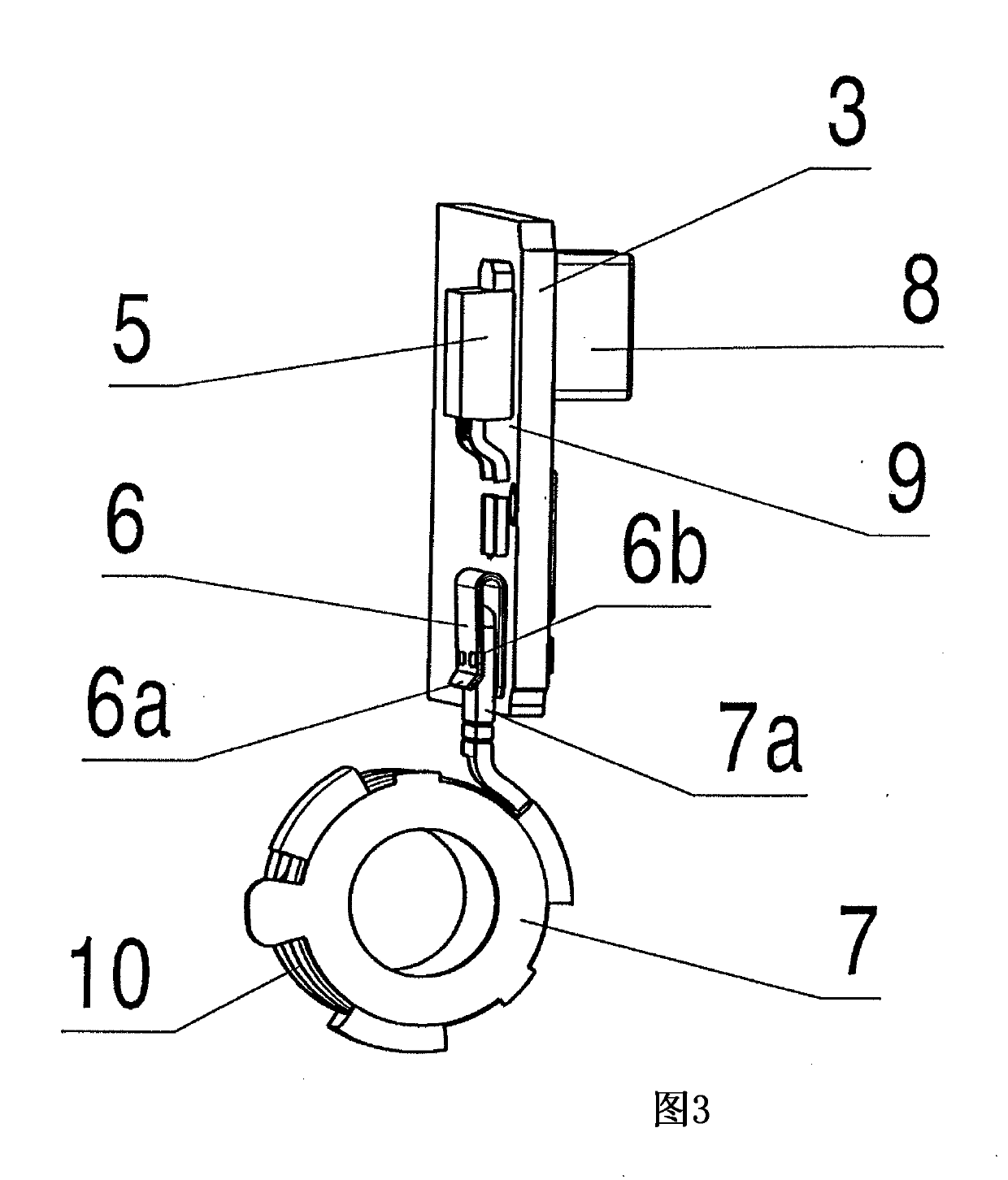

[0017] The control circuit contains power transistors 5 and thus generates considerable heat losses during operation. In order to dissipate this heat loss, the cooling body 6 is soldered, for example by SMD technology, onto the metal surface of the printed circuit board 1 , typically a copper surface. The cooling body 6 is plugged together with the heat dissipation component 7 , wherein the heat dissipation component 7 protrudes from the cavity wall of the plastic shell 1 . The cooling body 6 and the heat dissipation component 7 jointly form a thermal bridge, which dissipates the heat loss of the control circuit to the outside of the plastic casing 1 . The wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com