Method for producing at least one printing plate, and a printing plate

A printing plate and plane normal technology, applied in printing plate, printing plate preparation, printing, etc., can solve the problems of transmission interference printing pictures, etc., achieve the effect of improving printing quality, reducing maintenance cost, and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

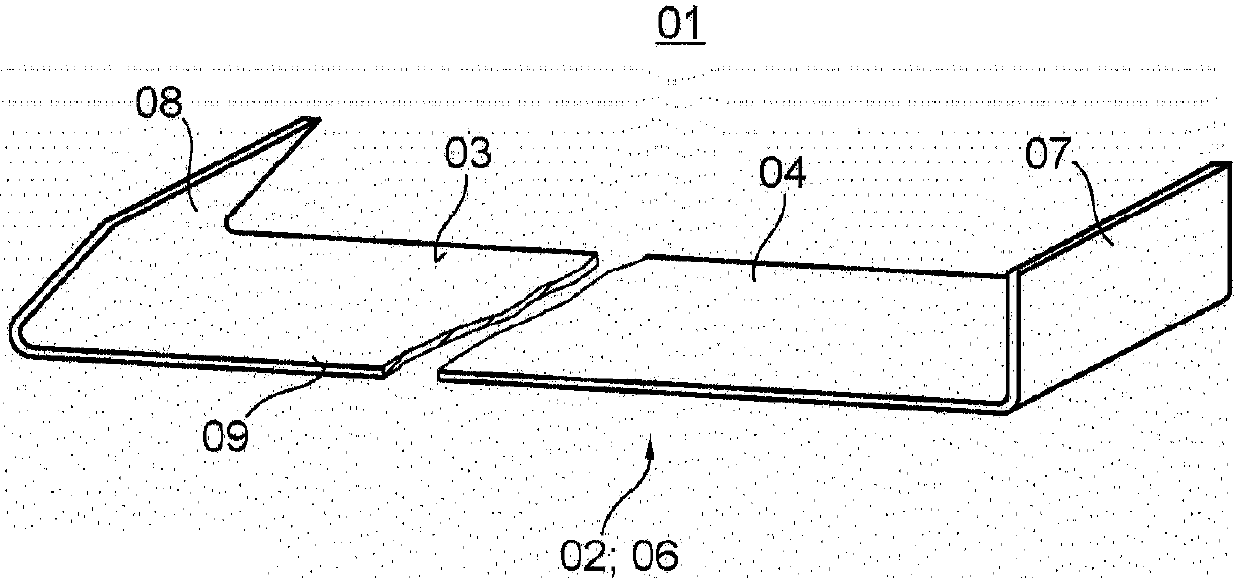

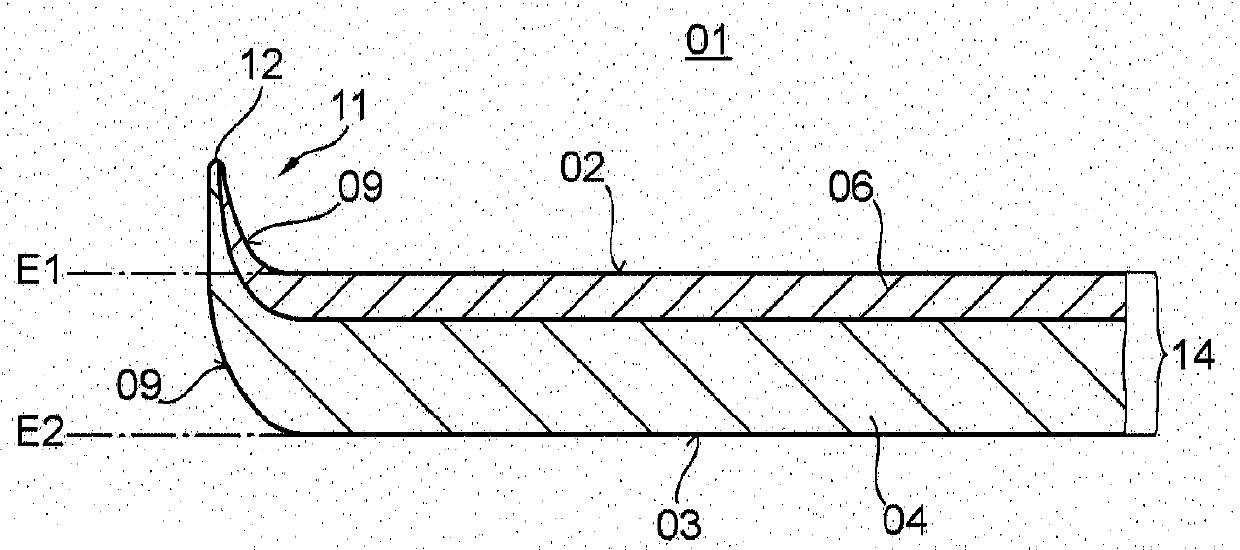

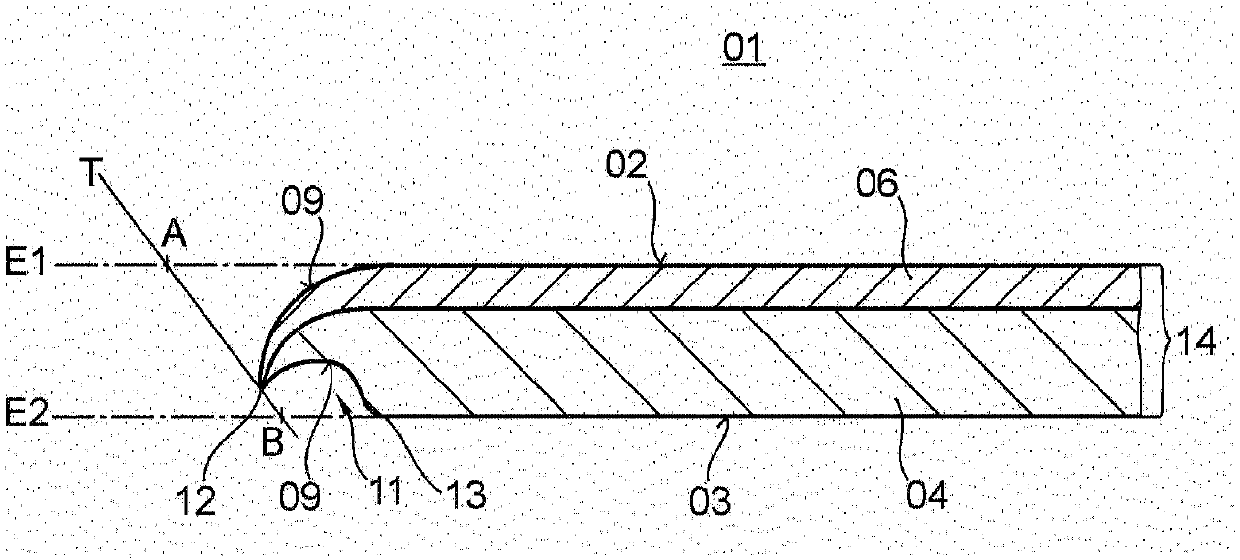

[0032] Printing plate 01 (e.g. printing plate 01, in particular lithographic printing plate 01) is designed as printing plate 01 of a printing press, e.g. machine) plate cylinder plate 01. Preferably the printing press is designed as a printing press for waterless offset printing. A corresponding offset printing unit has at least one plate cylinder (in particular a plate cylinder), a transfer cylinder (in particular a blanket cylinder) associated with the plate cylinder, and an impression cylinder associated with the transfer cylinder. At least one printing forme 01 is arranged on the forme cylinder. A plurality of printing formes 01 are preferably arranged successively on the printing plate cylinder in the direction of the rotational axis of the printing plate cylinder. Regardless of whether several printing formes 01 are arranged successively in the direction of the axis of rotation of the printing forme cylinder, several printing formes 01 can also be arranged one after t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap