Multilayer adhesive articles and adhesive sheets

A technology of adhesiveness and articles, applied in the direction of adhesive type, conductive adhesive, acidic copolymer adhesive, etc., can solve the problems of easy peeling and weak bonding force, and achieve the effect of inhibiting interlayer peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] (Synthesis of Acrylic Polymer (a))

[0154] Put 229 parts of ethyl acetate, 0.2 parts of azobisisobutyronitrile, 95 parts of n-butyl acrylate and 5 parts of acrylic acid into a reactor with a thermometer, a stirrer, a nitrogen gas inlet tube and a reflux condenser tube, and carry out at 60 ° C. Solution polymerization was carried out to obtain an acrylic polymer solution A having a concentration of the acrylic polymer (a) of 30% by weight. The weight average molecular weight of the said acrylic polymer (a) was 750,000.

[0155] (Synthesis of Acrylic Polymer (b))

[0156] In the reactor with thermometer, stirrer, nitrogen inlet pipe and reflux condenser, drop 146 parts of ethyl acetate, 0.2 part of azobisisobutyronitrile, 95 parts of 2-ethylhexyl acrylate and 5 parts of acrylic acid, Solution polymerization was performed at 60° C. to obtain an acrylic polymer solution B having a concentration of the acrylic polymer (b) of 40% by weight. The weight average molecular we...

Embodiment 2~14

[0163] [Examples 2 to 14, Comparative Example 1]

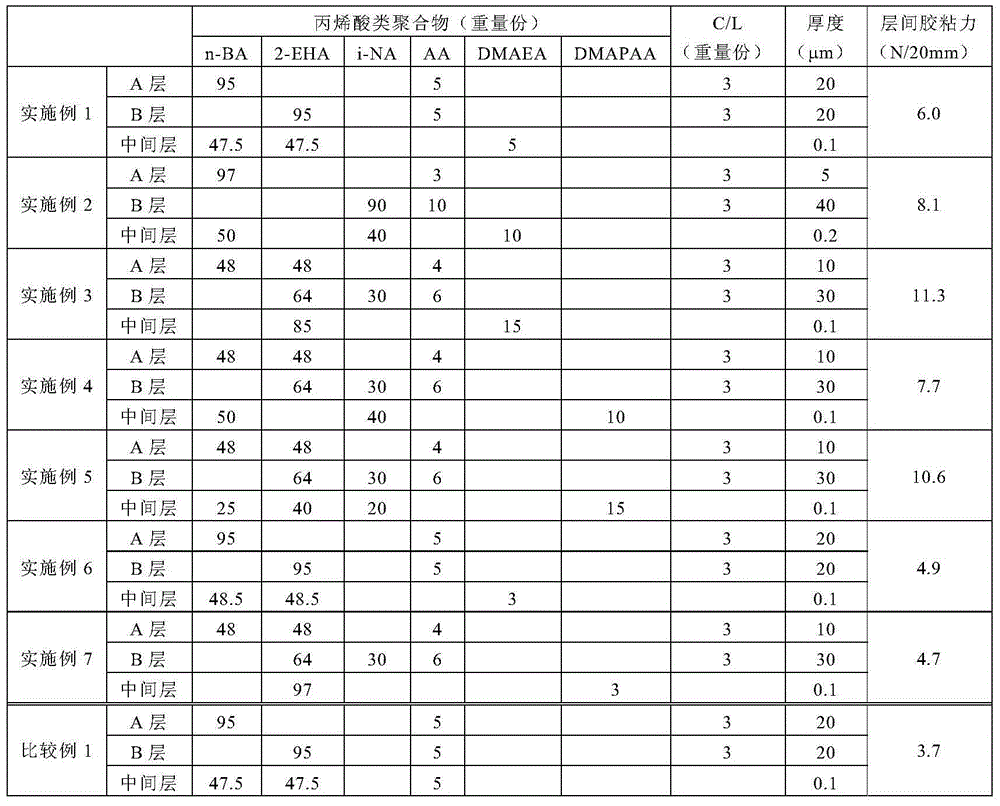

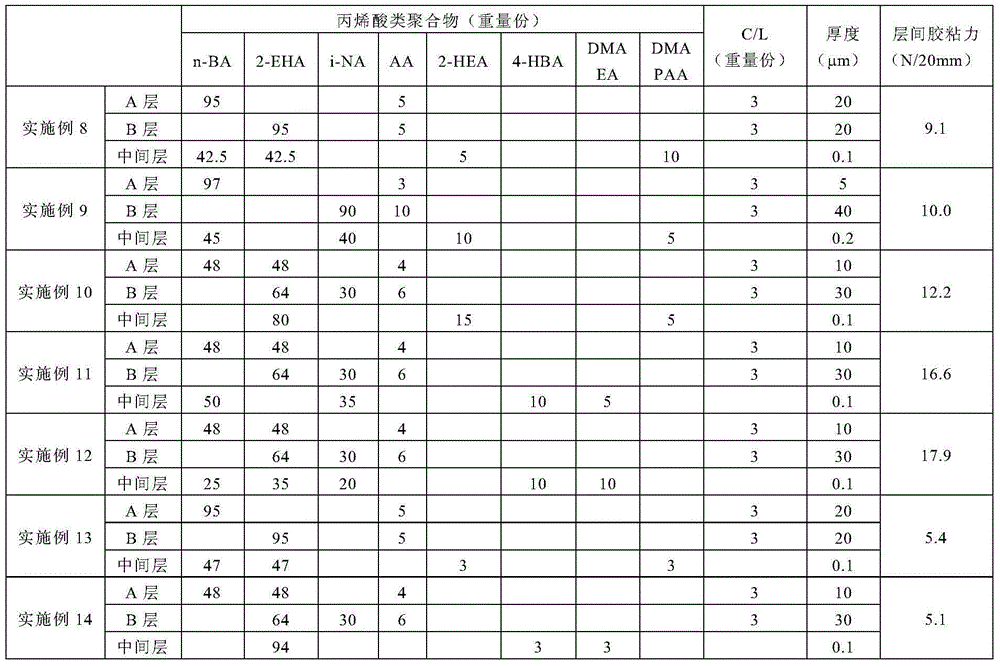

[0164] The types and amounts of the monomers used in the synthesis of the acrylic polymers (a) to (c), the amount of the crosslinking agent, and the thickness of each adhesive layer were changed to the values described in Table 1 and Table 2 , except that, the same operation as in Example 1 was performed, and each adhesive tape was produced.

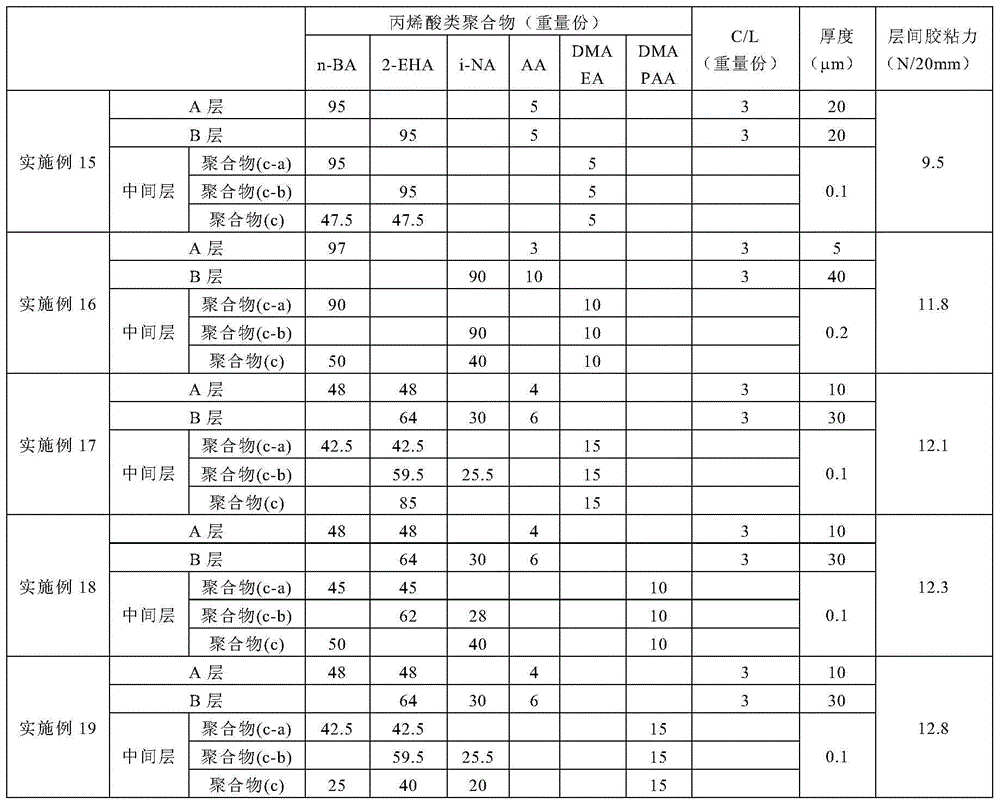

Embodiment 15

[0166] (Synthesis of Acrylic Polymer (a))

[0167] Put 229 parts of ethyl acetate, 0.2 parts of azobisisobutyronitrile, 95 parts of n-butyl acrylate and 5 parts of acrylic acid into a reactor with a thermometer, a stirrer, a nitrogen gas inlet tube and a reflux condenser tube, and carry out at 60 ° C. Solution polymerization was carried out to obtain an acrylic polymer solution A having a concentration of the acrylic polymer (a) of 30% by weight. The weight average molecular weight of the said acrylic polymer (a) was 750,000.

[0168] (Synthesis of Acrylic Polymer (b))

[0169] In the reactor with thermometer, stirrer, nitrogen inlet pipe and reflux condenser, drop 146 parts of ethyl acetate, 0.2 part of azobisisobutyronitrile, 95 parts of 2-ethylhexyl acrylate and 5 parts of acrylic acid, Solution polymerization was performed at 60° C. to obtain an acrylic polymer solution B having a concentration of the acrylic polymer (b) of 40% by weight. The weight average molecular we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com