A circulating material distribution system for producing ceramic wall and floor tiles

A technology for circulating cloth, wall and floor tiles, applied in supply devices, manufacturing tools, etc., can solve the problems of high cost, unfavorable production scale, and wide area, so as to reduce site occupation, improve equipment utilization, and save investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

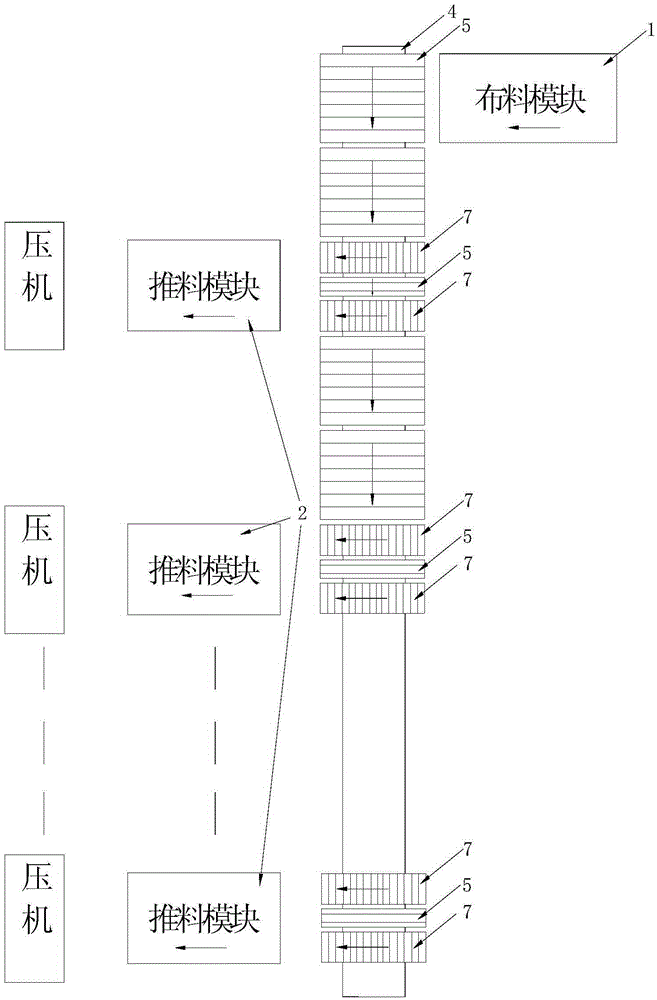

[0029] Embodiment 1: as Figure 1-7 As shown, a circulating distribution system for producing ceramic wall and floor tiles includes a distribution module 1, five pushing modules 2, a pallet 3 and a two-way horizontal conveying platform 4.

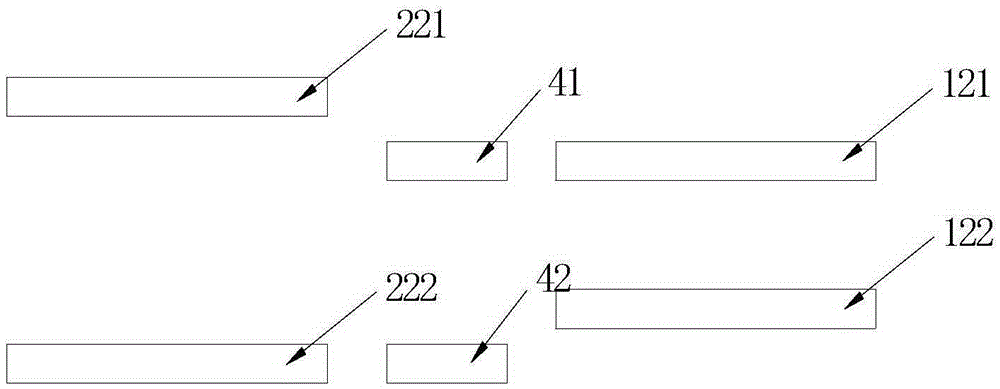

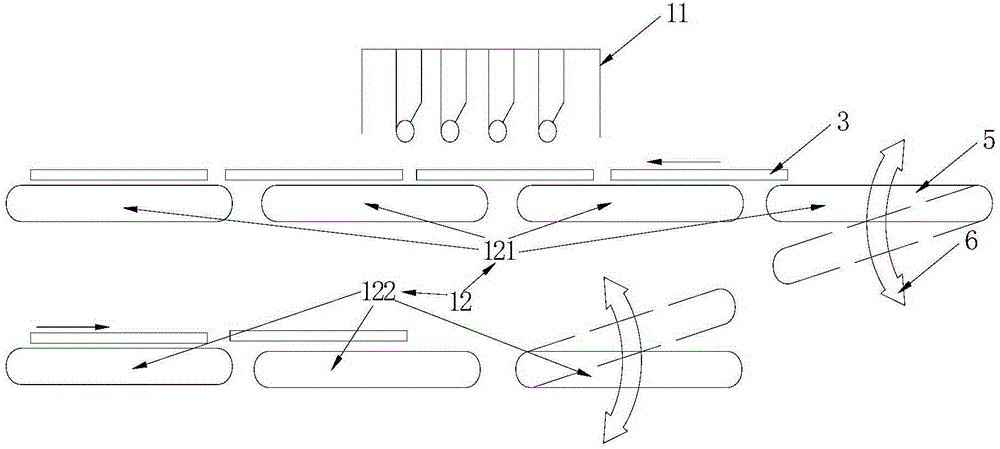

[0030] The cloth module 1 is composed of a cloth station device 11, a cloth horizontal conveying platform 12 and a cloth lifting device. In this embodiment 1, the cloth horizontal conveying platform 12 is made up of several groups of belt transmission mechanisms 5, including the upper cloth horizontal conveying platform 121 and the lower cloth horizontal conveying platform 122, which are arranged side by side in two layers, the upper cloth horizontal conveying platform 121 and the lower cloth horizontal conveying platform 122. The conveying lengths of the lower cloth horizontal conveying platforms 122 are equal. The belt transmission mechanism 5 is an existing general belt transmission mechanism, and the required quantity is determined acc...

Embodiment 2

[0035] Embodiment 2: as Figure 8-9 As shown, the difference between Embodiment 2 and Embodiment 1 is that the lateral conveying device in the two-way horizontal conveying platform 4 adopts a belt changing mechanism 10, and the forward conveying device adopts a roller bar transmission mechanism 7, and the belt changing mechanism 10 is installed Below the roller bar transmission mechanism 7, its functional structure is consistent with the belt transmission mechanism 5, and its belt width is the length of the supporting plate 3 The reversing device is made up of cylinder 8 and elevating supporting bar 9, is installed in the belt reversing mechanism 10. When the cylinder 8 moves, the lifting bracket 9 goes up and contacts the belt. After rising to a certain height, the air rod 8 stops moving and keeps the cylinder shaft stretched out. At this time, the belt is tightened by the lifting bracket 9, and the belt changing mechanism 10 is in the working position, and the conveying su...

Embodiment 3

[0036] Embodiment 3: as Figure 10 As shown, the difference between embodiment 3 and embodiment 1 is that the cloth horizontal conveying platform 12, the two-way horizontal conveying platform 4 and the pushing material horizontal conveying platform 22 are arranged in a random arrangement of upper and lower layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com