Heat conducting double sided tape and preparation process thereof

A technology of double-sided tape and thermal conductive layer, applied in the direction of adhesives, non-polymer adhesive additives, film/sheet adhesives, etc. problem, to achieve the effect of good thermal conductivity and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

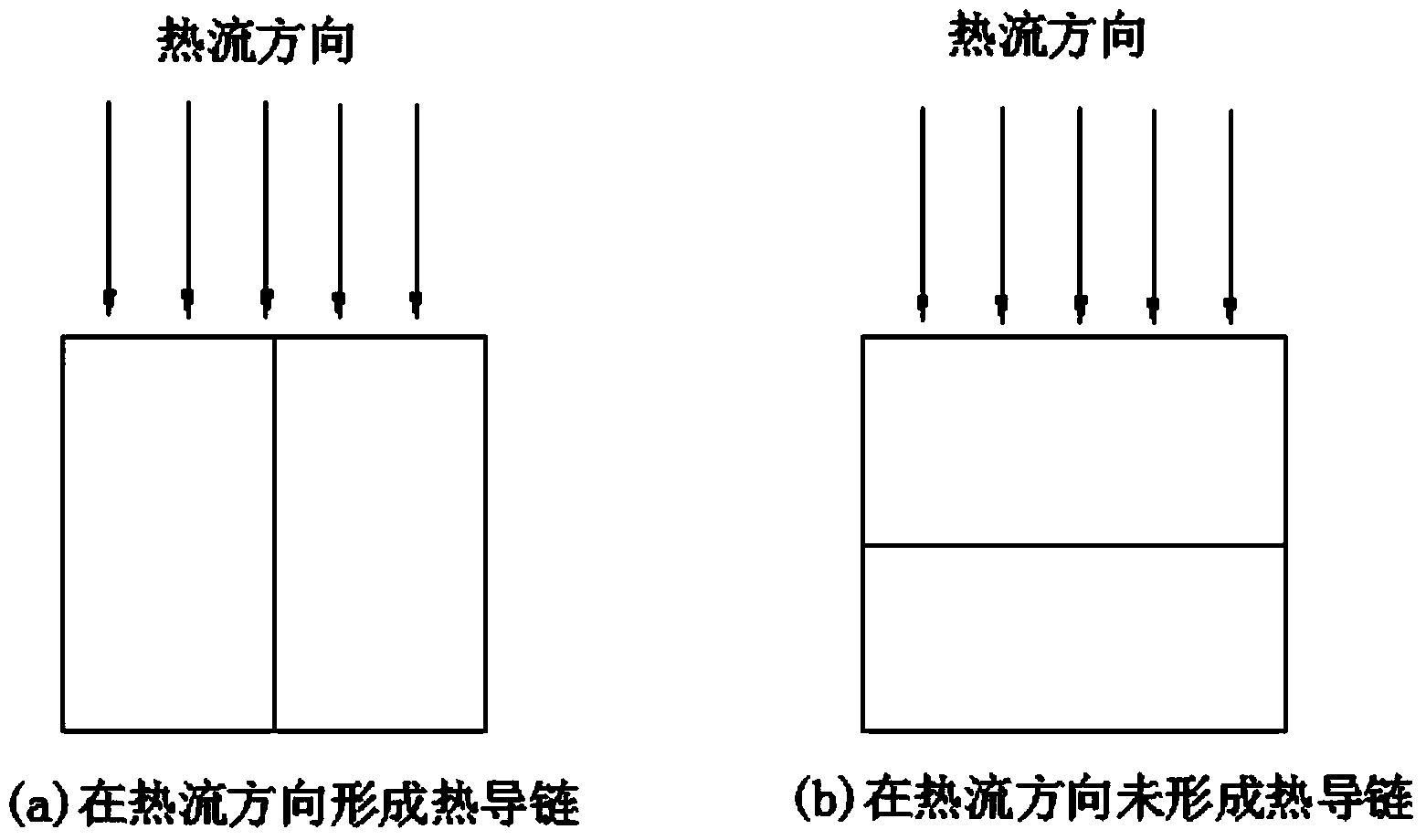

Problems solved by technology

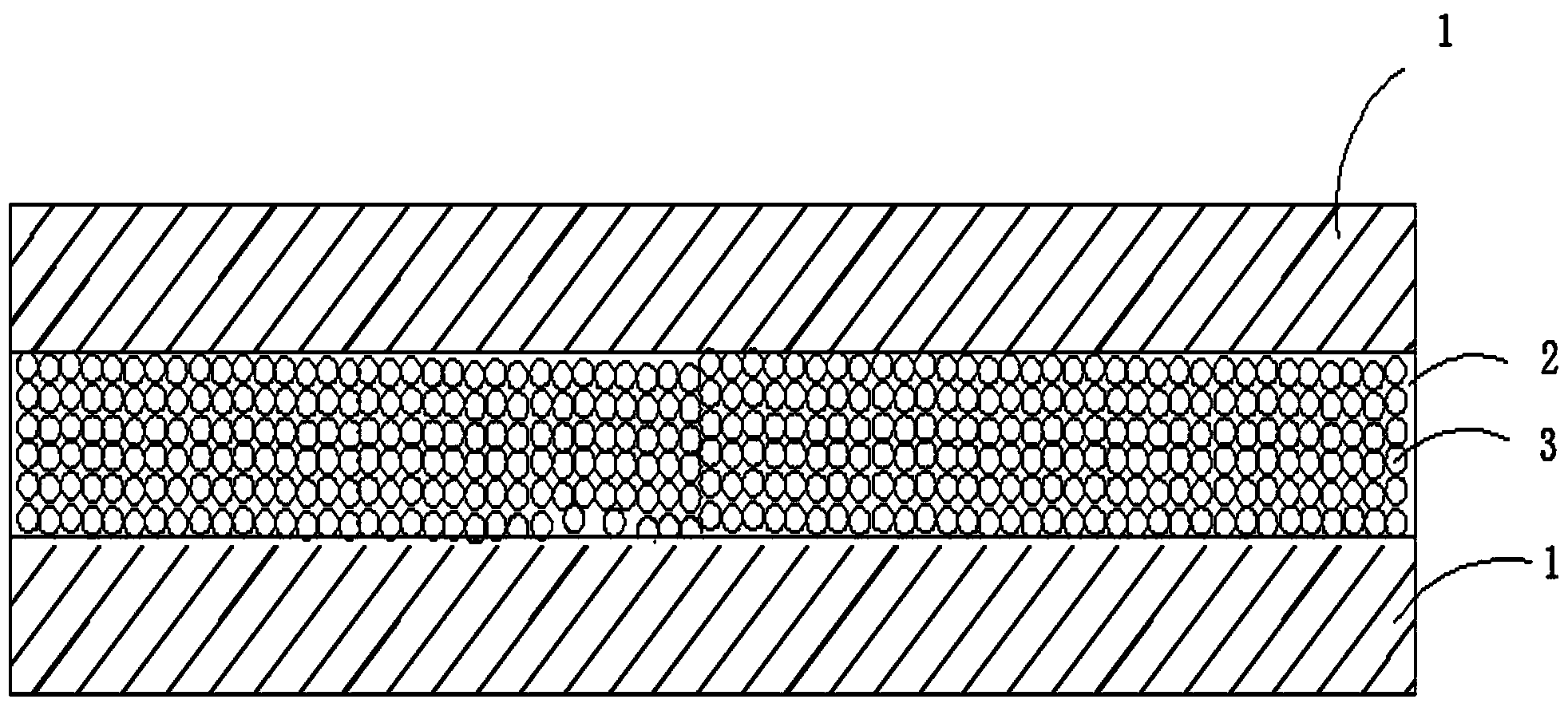

Method used

Image

Examples

experiment example 1

[0029] Formula: acrylic acid polymer: 85%, graphite: 15%, and the graphite is graphite with a particle size of 4um.

[0030] Preparation process: a. Put the graphite in a vacuum drying oven to dry for half an hour;

[0031] b. Weigh the nano-graphite powder and add it to the silane coupling agent KH-550 for surface modification, and stir for 24 hours during the modification process;

[0032] c. After centrifugation, filtration and other steps, the surface-modified graphite powder is put into a vacuum drying oven for drying.

[0033] d. Add the dried graphite powder into the acrylic glue and stir for 2 hours to ensure uniform stirring.

[0034] e. Gluing: Use gluing equipment to evenly coat the evenly stirred glue on the release film, and pay attention to controlling the thickness of the glue to 0.05mm during the gluing process.

[0035] f. Detect the thermal conductivity of the prepared thermally conductive double-sided tape, testing equipment: thermal conductivity tester

...

experiment example 2

[0039] Formula: acrylic acid polymer: 64%, graphite: 36%, and the graphite is graphite with a particle size of 4um.

[0040] Preparation process: a. Put the graphite in a vacuum drying oven to dry for half an hour;

[0041] b. Weigh the nano-graphite powder and add it to the silane coupling agent KH-550 for surface modification, and stir for 24 hours during the modification process;

[0042] c. After centrifugation, filtration and other steps, the surface-modified graphite powder is put into a vacuum drying oven for drying.

[0043] d. Add the dried graphite powder into the acrylic glue and stir for 2 hours to ensure uniform stirring.

[0044] e. Gluing: Use gluing equipment to evenly coat the evenly stirred glue on the release film, and pay attention to controlling the thickness of the glue to 0.05mm during the gluing process.

[0045] f. Detect the thermal conductivity of the prepared thermally conductive double-sided tape, testing equipment: thermal conductivity tester

...

experiment example 3

[0052] Formulation: Acrylic Polymer: 50%; Graphite: 20%, Boron Nitride: 10%, Aluminum Nitride: 10% and Aluminum Oxide: 10%. The graphite adopts graphite with a particle diameter of 4um, the boron nitride adopts boron nitride with a particle diameter of 4um, the boron nitride adopts boron nitride with a particle diameter of 4um, and the described aluminum oxide adopts a particle diameter of 4um. Aluminum oxide of 4um.

[0053] Preparation process: a. Put graphite, boron nitride, aluminum nitride and aluminum oxide into a vacuum drying oven and dry for half an hour;

[0054] b. Weigh a certain amount of graphite, boron nitride, aluminum nitride and aluminum oxide and add them to KH-550 or NDZ-131 for surface modification, and stir for 24 hours during the modification process;

[0055] c. After centrifugation, filtration and other steps, the surface-modified graphite, boron nitride, aluminum nitride and aluminum oxide mixed powder is put into a vacuum drying oven for drying.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com