Pavement deflection full-field laser detection method and system

A laser detection and road surface deflection technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of difficult span, can not be used as standard measurement, unclear measurement base point, etc., to achieve reliable measurement benchmark and improve measurement performance. , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

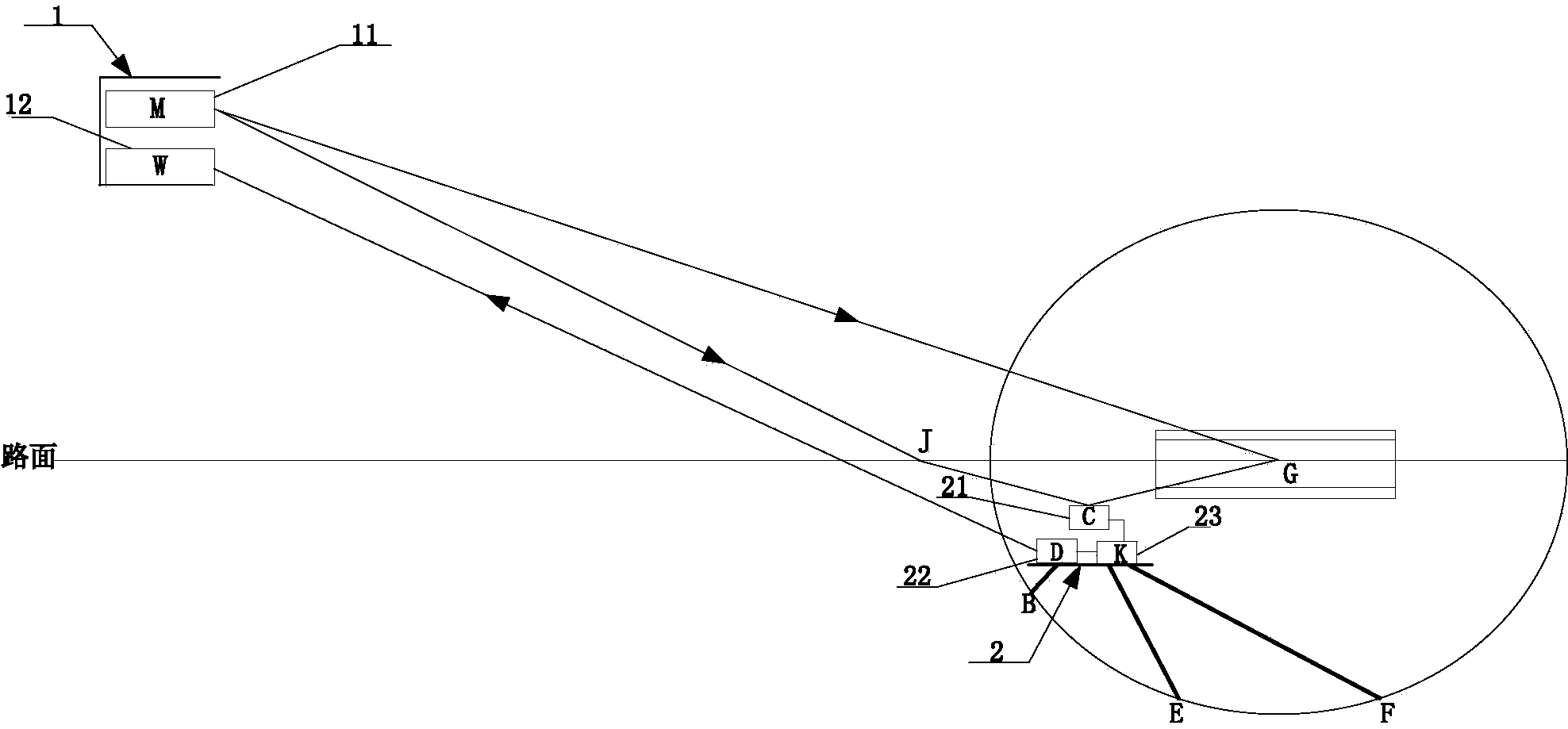

[0039] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

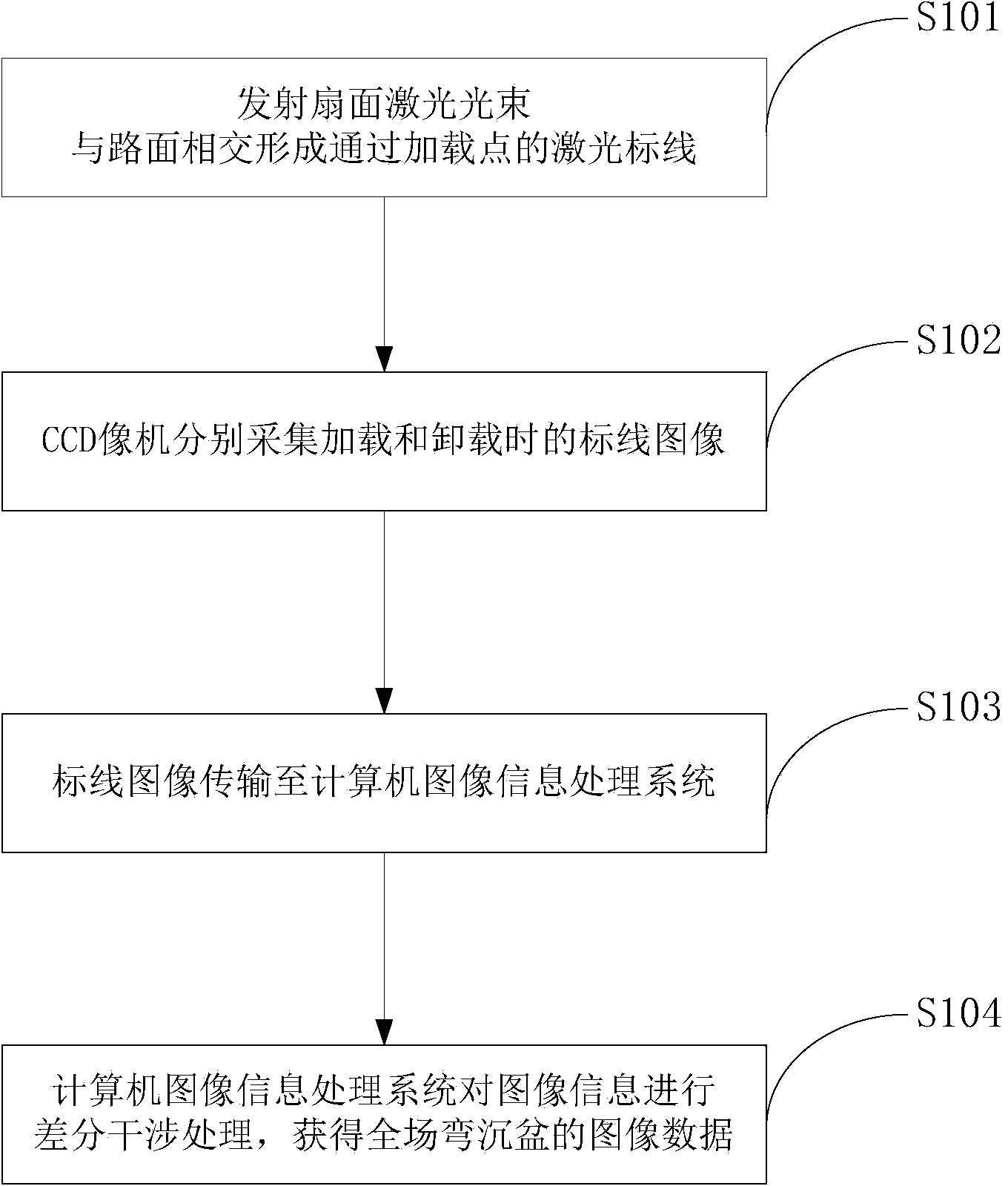

[0040] figure 1 It is an exemplary flowchart of a full-field laser detection method for road surface deflection according to an embodiment of the present invention, wherein a full-field laser detection method for road surface deflection starts at step S101 and ends after step S104.

[0041] In step S101, a sectoral laser beam is emitted to the road surface to be tested to form a laser marking line passing through the loading point of the road surface to be tested.

[0042] The loading point is located at the center of the rear axle of the standard load vehicle, and the standard load vehicle refers to a load vehicle loaded with a standard mass of 10T.

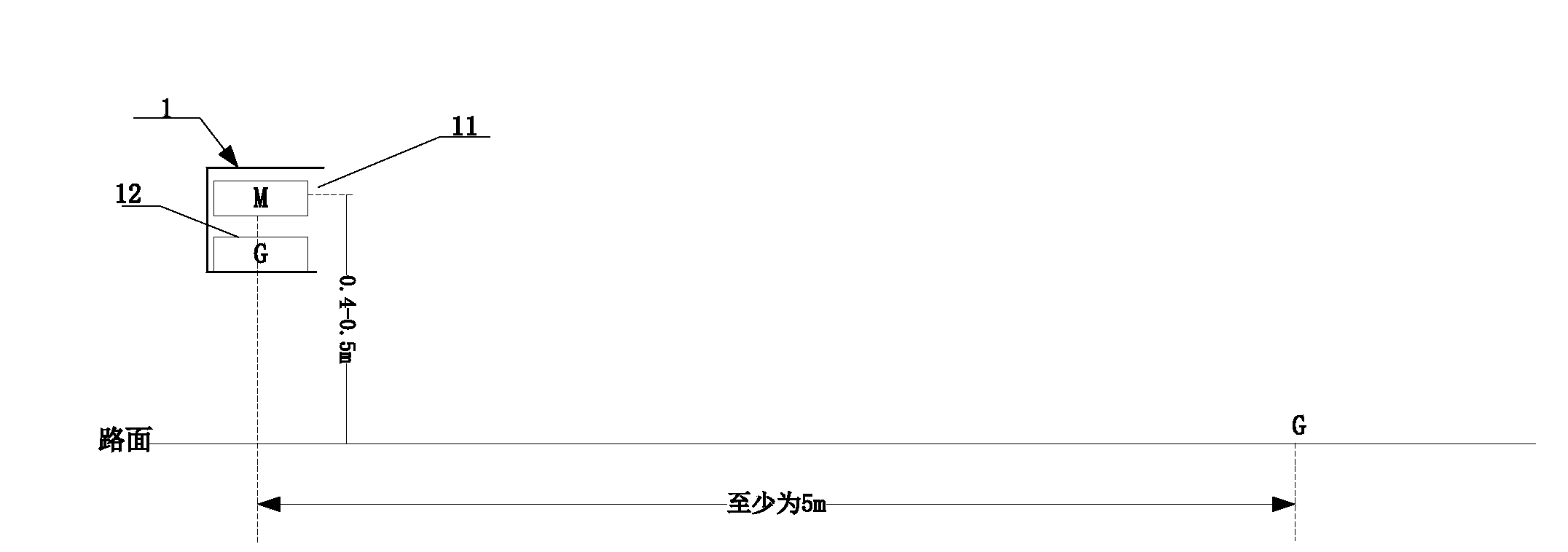

[0043] As a preferred embodiment, in order to prevent the change of the measurement reference from affecting the measurement result, the fan laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com