Kiln furniture (kiln car) used for firing of ceramic counter basin frame structures

A frame structure and kiln furniture technology, which is applied in the field of kiln furniture and kiln cars, can solve problems such as low loading density, high labor intensity, and dark cracks in the basin, and achieve the effects of increasing loading density, reducing labor intensity, and improving product grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

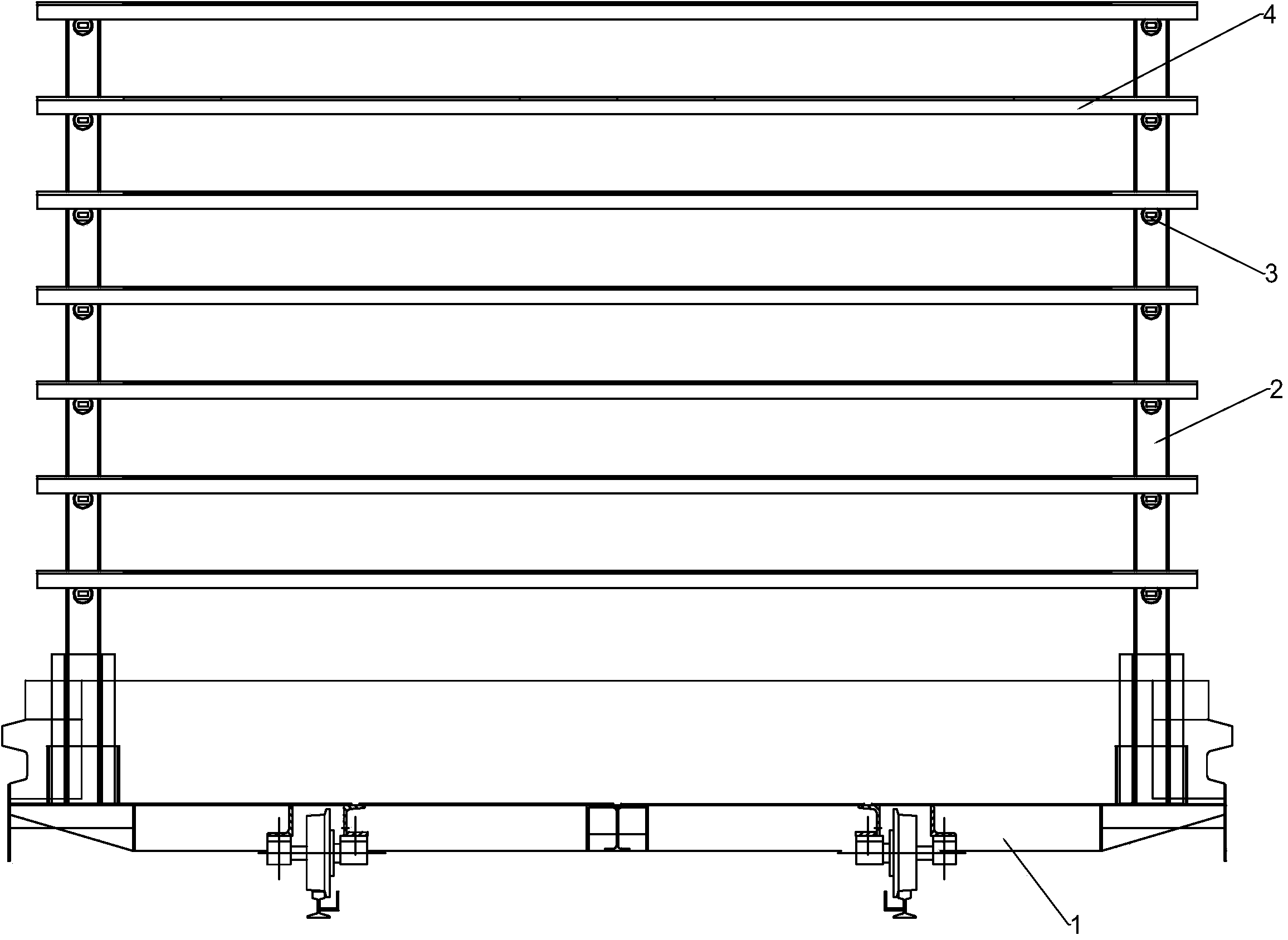

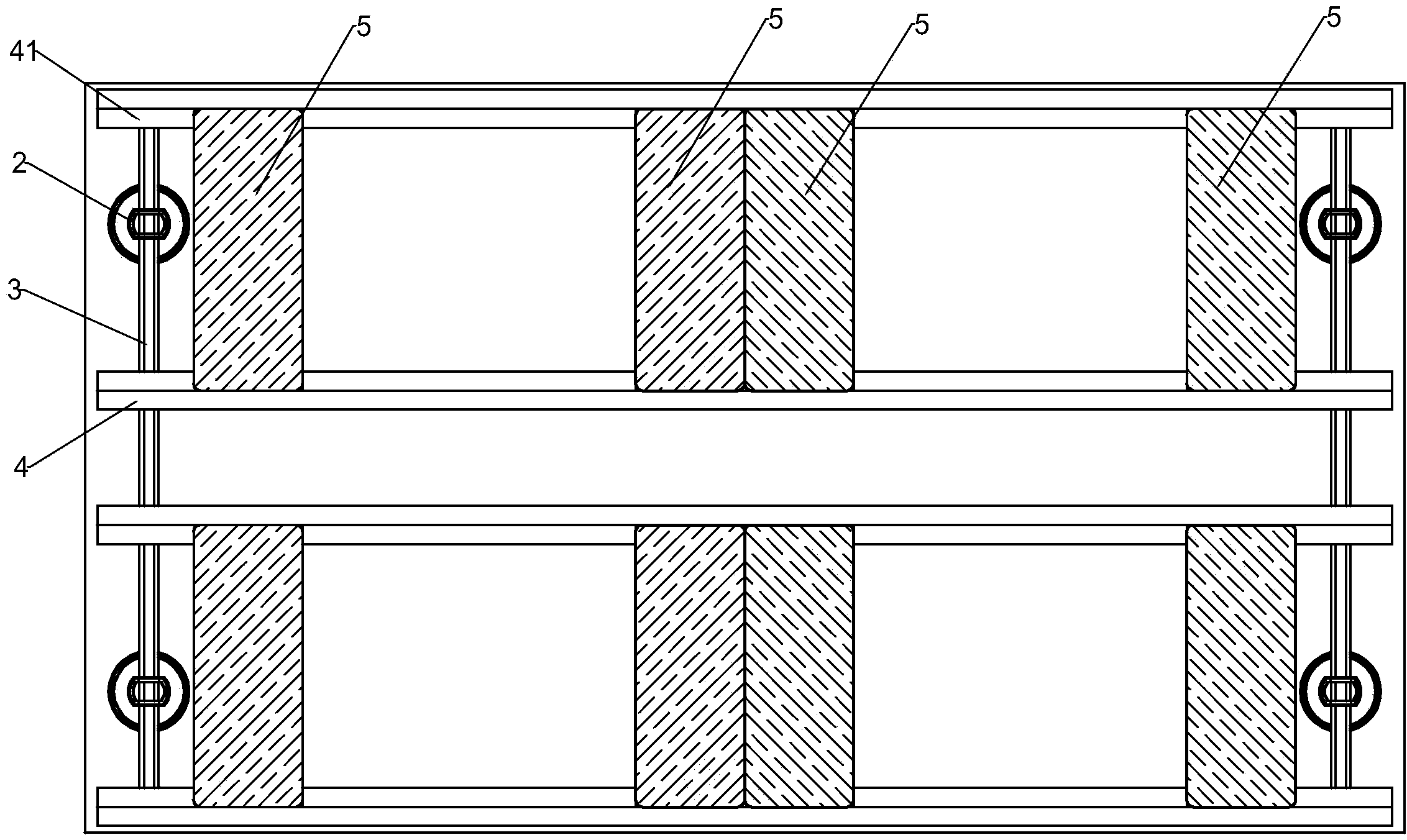

[0025] Embodiment 1, with reference to Figure 1- Figure 7 , a kind of kiln furniture kiln car used in firing ceramic table basin frame structure, including vehicle frame 1, column 2, beam 3 and joist 4, is provided with 4 columns 2 on vehicle frame 1, and each column 2 Layer frame through holes are arranged on the vehicle frame, and layer frame crossbeams 3 are arranged on the width direction of the vehicle frame. 2 groups of 4 joists 4 in total, the joists 4 are erected on the left and right beams 3, and 4 supporting plates 5 are erected between each group of joists 4, the joists 4 are double holes with steps Rectangular cylindrical body, the steps 41 are low-level steps, the height of the steps 41 is equal to the thickness of the supporting plate 5, the steps 41 on each group of joists 4 are oppositely arranged, and the supporting plates 5 are erected on the same group 2 between the steps 41 of the root joists 4 .

Embodiment 2

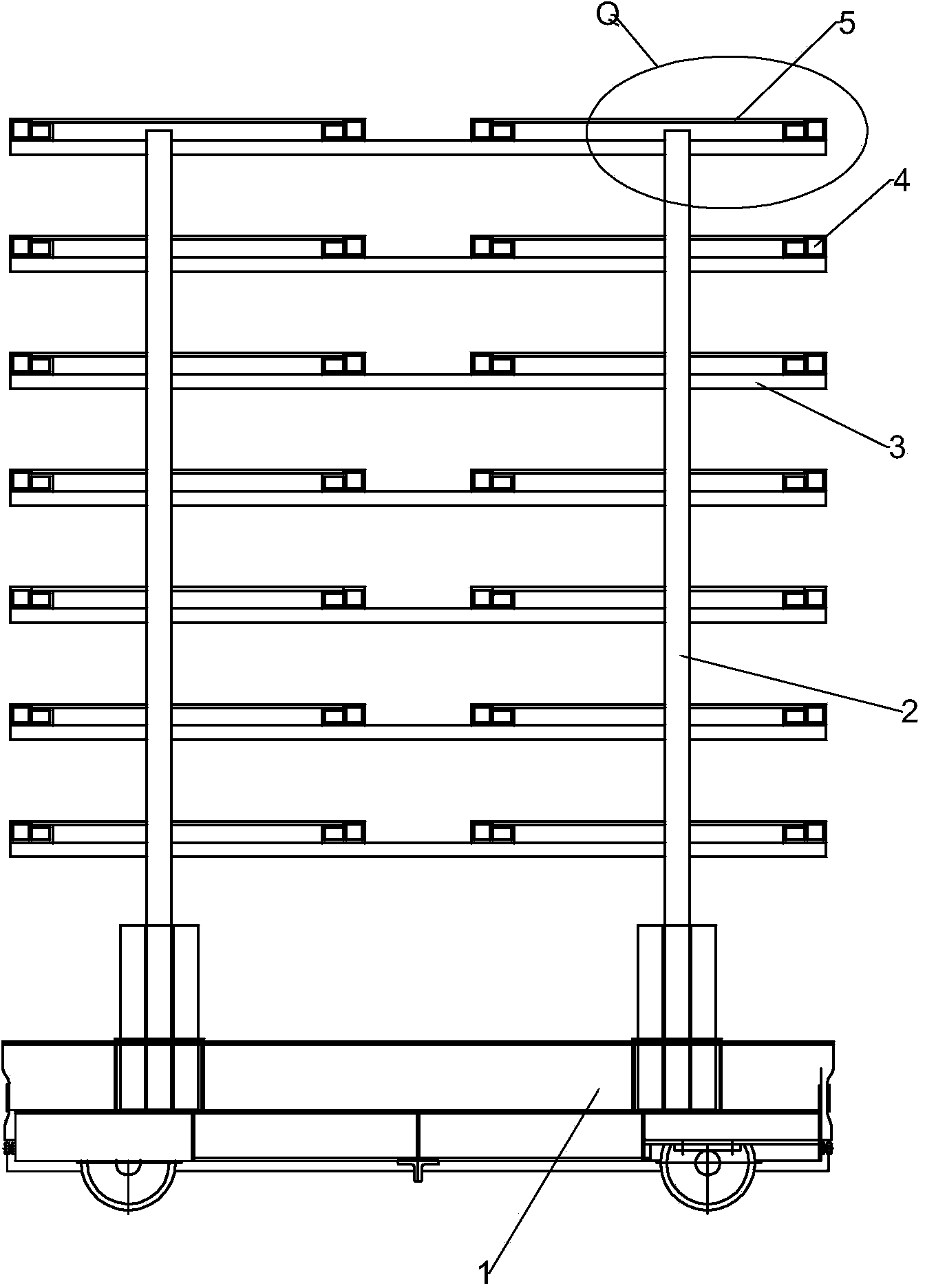

[0026] Embodiment 2, with reference to Figure 8-Figure 10 , a kind of kiln furniture kiln car used in firing ceramic table basin frame structure, including vehicle frame 1, column 2, beam 3 and joist 4, is provided with 6 columns 2 on vehicle frame 1, and each column 2 Layer frame through holes are arranged on the vehicle frame, and layer frame crossbeams 3 are arranged on the width direction of the vehicle frame. There are 8 joists 4 in 4 groups, and the joists 4 are erected on two adjacent beams 3, and two supporting plates 5 are erected between each group of joists 4, and the joists 4 are double-layered with steps Hole rectangular cylindrical body, the step 41 is a lower step, the height of the step 41 is equal to the thickness of the supporting plate 5, the steps 41 on each group of joists 4 are arranged oppositely, and the supporting plate 5 is erected on the same group between the steps 41 of the two joists 4 . On the joist 4 steps 41 between every 1 group of supporti...

Embodiment 3

[0027] Embodiment 3, with reference to Figure 11 , a kind of kiln furniture kiln car that is applied to firing ceramic basin frame structure compares with embodiment 2, and its difference is: use longer joist 4, and the length of joist 4 is the same as embodiment 1, each joist 4 can straddle on 3 upright columns 2 at the same time, and other structures are identical with embodiment 2.

[0028] The kiln furniture kiln car described in embodiment 1-embodiment 3 has 7 layers in total, and each layer can be loaded with 4 pieces of ceramic basins. Figure 5 The pallets shown are suitable for loading with straight-sided structural ceramic washbasins, Figures 6A-6E The pallets shown are suitable for loading ceramic washbasins with curved structures or special-shaped structures. You can choose (or design) pallets of different shapes to burn different shapes of basins.

[0029] In the present invention, the frame structure is not limited by the embodiment. The kiln car can be desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com