Slag cooler for calcinator

A roasting furnace and slag cooler technology, applied in the field of slag residual heat utilization, can solve the problems of no slag waste heat utilization equipment and immature slag, and achieve high reliability, convenient installation and operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

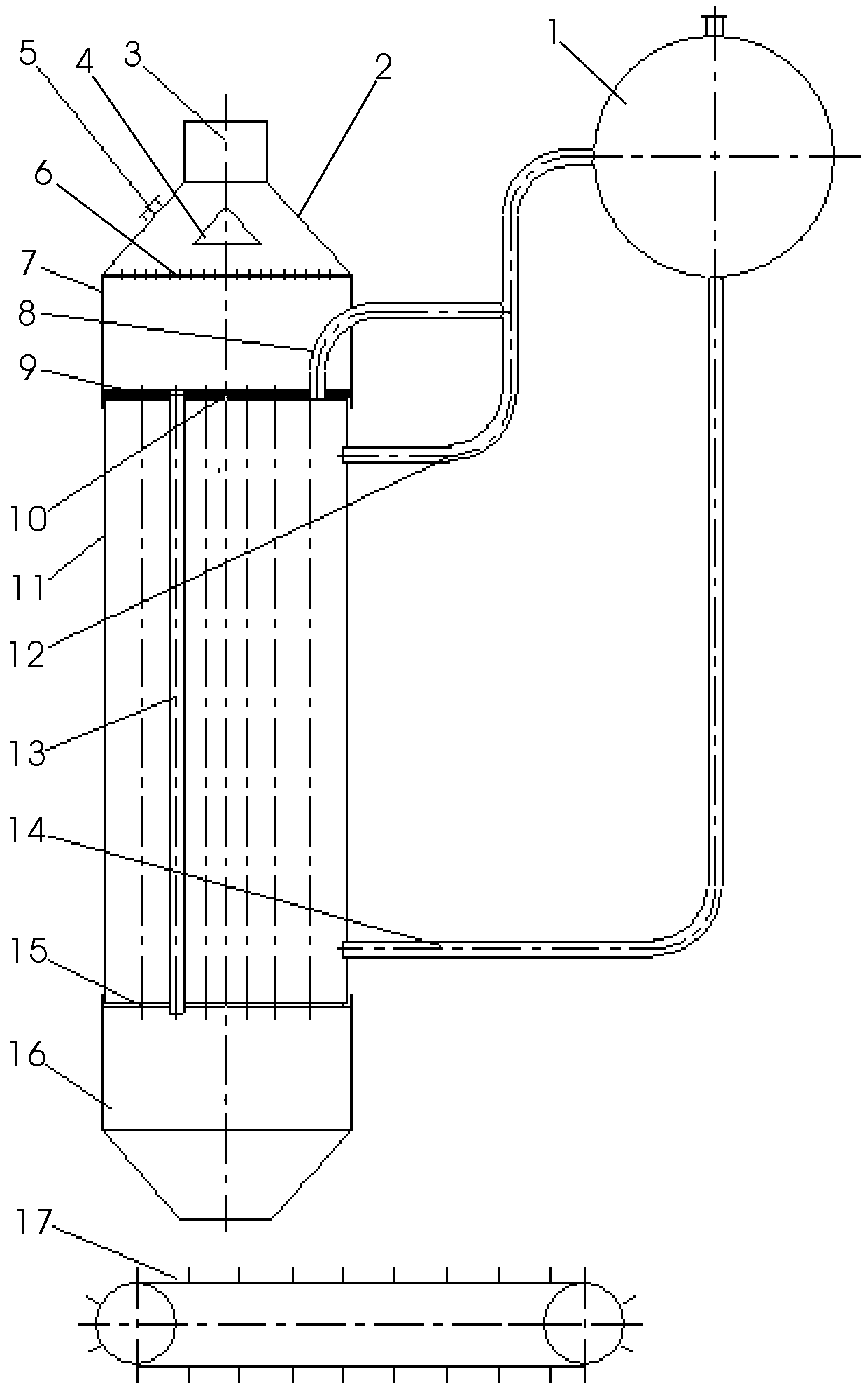

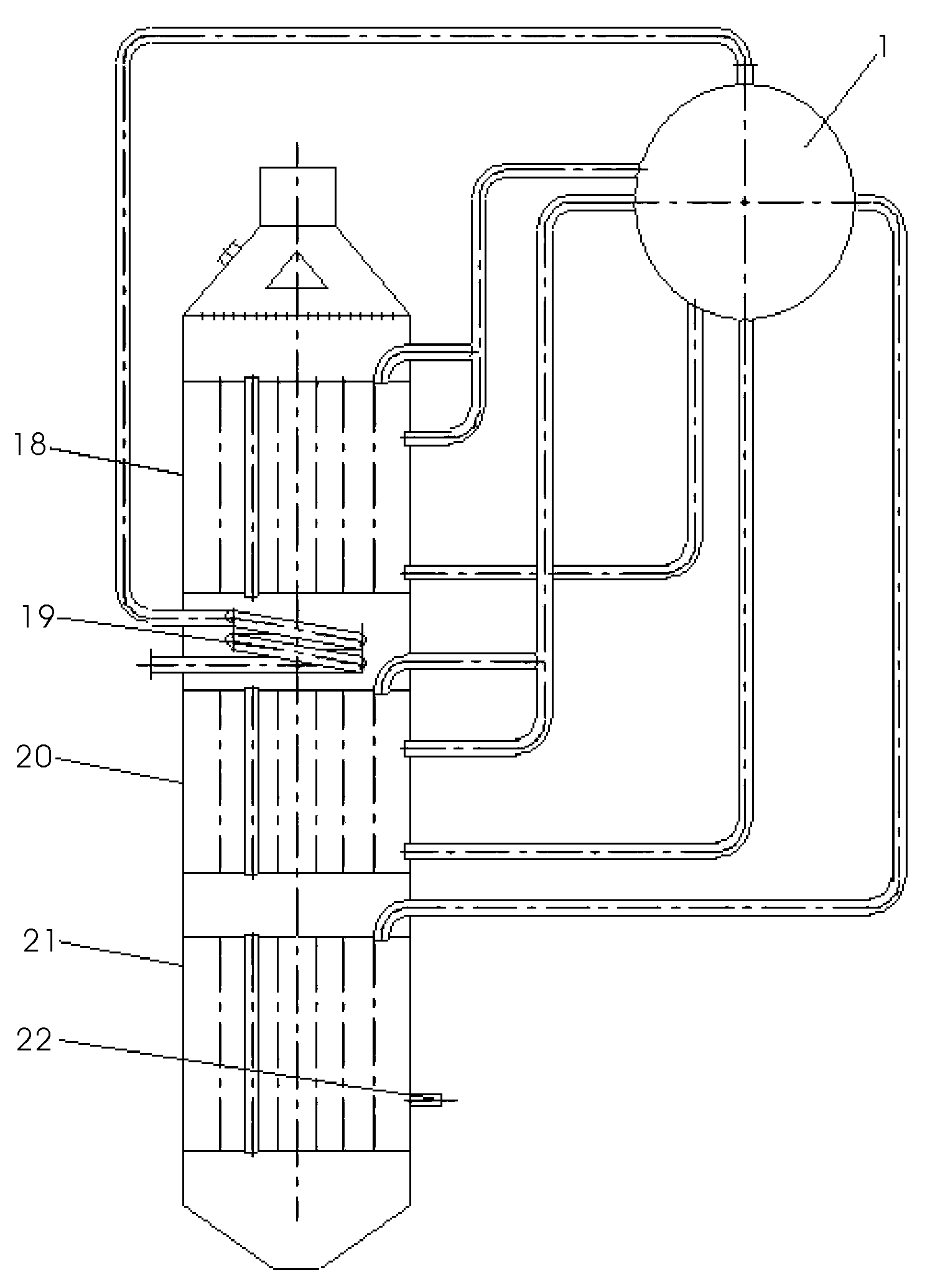

[0008] Now refer to the attached figure 1 And attached figure 2 , described as follows in conjunction with the embodiment: A kind of slag cooler for roasting furnace according to the present invention includes a steam drum 1, an upper end cover 2, a slag inlet 3, a split flow equalizing device 4, an inspection door 5, a leveling layer Flow equalizing device 6, sealing cover plate 7, upper steam-water connecting pipe 8, refractory material 9, upper tube plate 10, outer cylinder body 11, lower steam-water connecting pipe 12, fire pipe 13, descending pipe 14, lower tube plate 15, outlet Slag port 16, slag remover 17, upper evaporator 18, superheater 19, lower evaporator 20, economizer 21 and water supply pipe seat 22. The outer cylinder 11 is the main body of a slag cooler for roasting furnaces according to the present invention, and has a cylindrical structure as a whole. The basic structural form can also be set in a two-stage or multi-stage form on the basis of a single-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com