A kind of LED wafer testing method and testing system

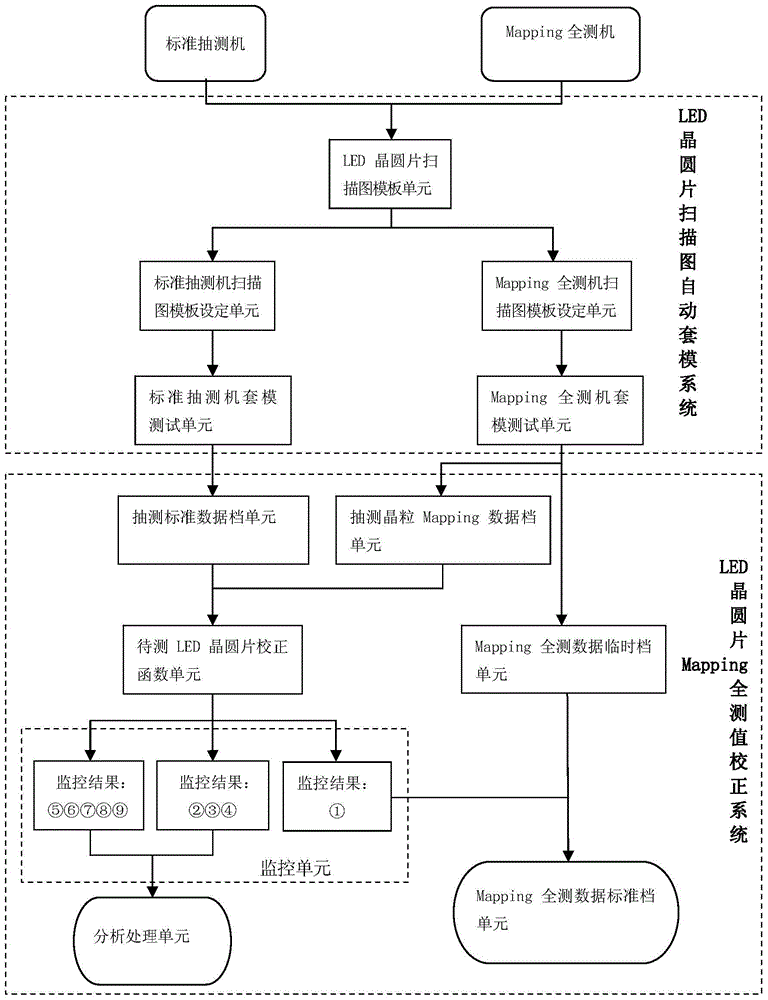

A test method and wafer technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of LED wafer Mapping full measurement value error, affecting production cycle, batch rework, etc., to achieve Solve the problem of hysteresis in abnormal control and improve production efficiency and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] First, the parameters involved in the implementation steps of the present invention are described as follows:

[0060] WL.offset: wavelength correction function after differentiation;

[0061] IV.gain: light intensity correction function after differentiation;

[0062] WL.std: The wavelength value of the sampled die when the LED wafer to be tested is sampled by the standard sampler;

[0063] IV.std: The light intensity value of the die to be tested when the LED wafer to be tested is sampled by the standard sampler;

[0064] WL.smap: The wavelength value of the random test die tested by the Mapping full test machine;

[0065] IV.smap: sample the light intensity value of the die tested by the Mapping full measuring machine;

[0066] WL.map: the initial wavelength value of the LED wafer to be tested in the Mapping full test machine;

[0067] IV.map: The initial light intensity value of the LED wafer to be tested in the Mapping full test machine;

[0068] WL (final): The final wavelength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com