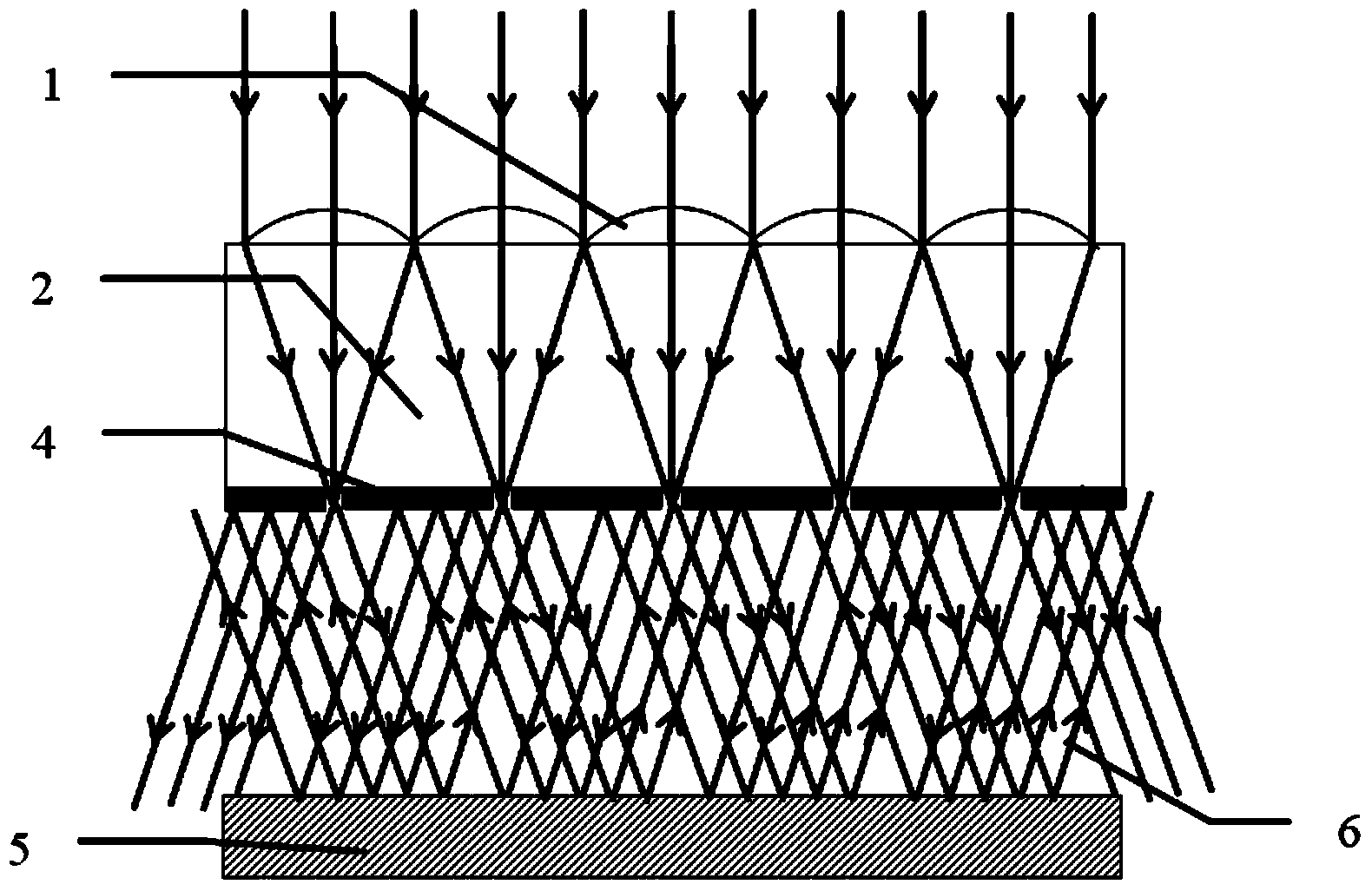

Light trapping structure for thin film solar cell and manufacturing method thereof

A technology for a solar cell and a light trapping structure, which is applied in the field of solar cells, can solve the problems of limited light trapping effect and complicated processing of the light trapping structure, and achieves the effects of simple structure, wide application range and strong light trapping ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

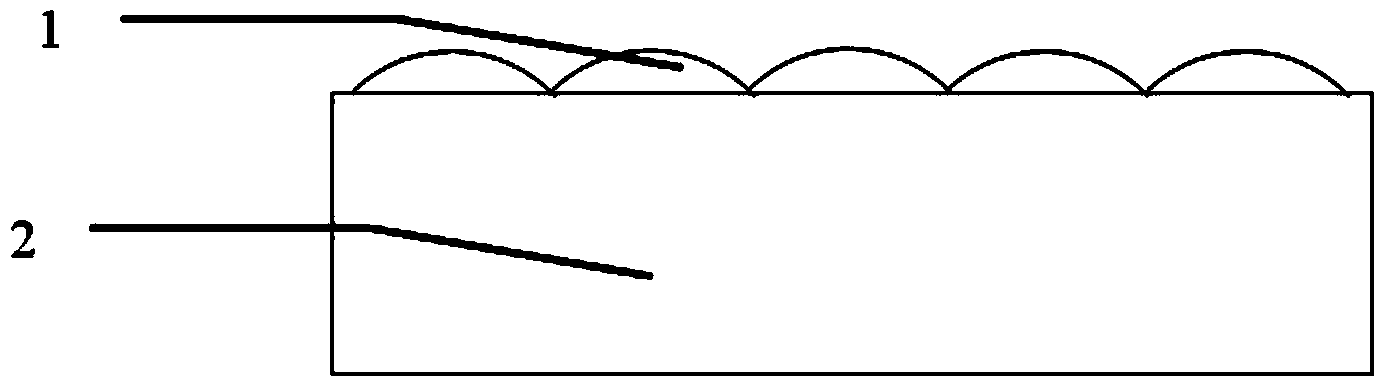

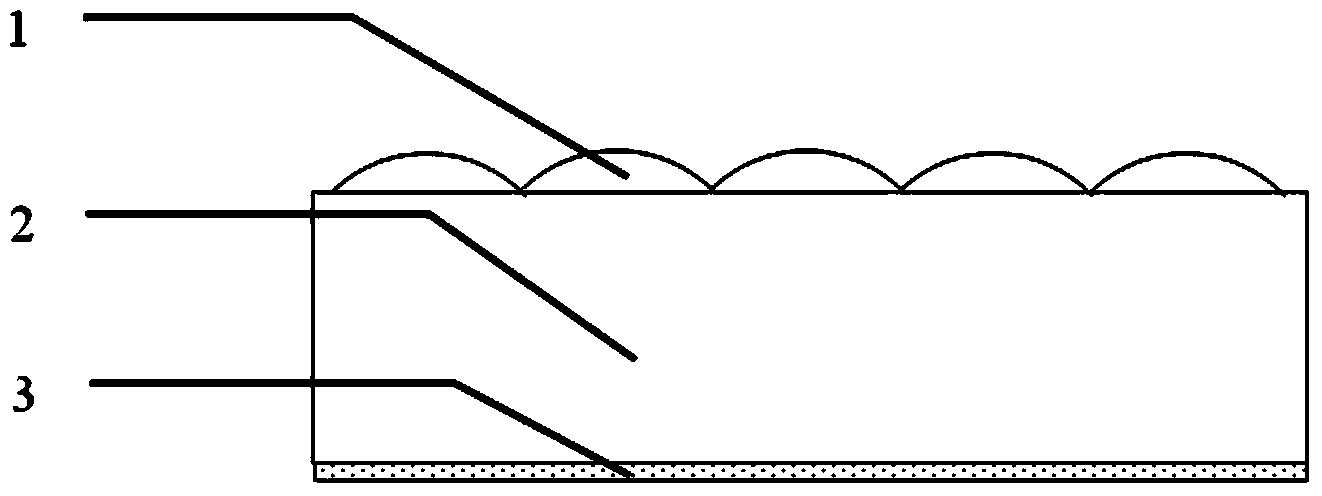

[0043] Embodiment 2 of the present invention is a light-trapping structure with a microlens diameter of 400 μm, a focal length of 2 mm in the base material, and a lens center spacing of 600 μm. The material of the microlens is plastic, and the base thickness is 2 mm.

[0044] The processing steps of the light trapping structure are:

[0045] (1) Make a microlens array on a plastic substrate with a thickness of 2 mm by hot pressing. The diameter of the microlens array is 400 μm, the focal length in the plastic substrate is 2 mm, and the lens center spacing is 600 μm;

[0046] (2) Coating a layer of negative photoresist with a thickness of 1um on the lower surface of the microlens substrate and pre-baking;

[0047] (3) Use a 365nm ultraviolet exposure machine to irradiate the upper surface of the microlens array to expose the negative photoresist at the focus of the microlens;

[0048] (4) After the exposed negative photoresist is developed, a dot matrix photoresist pattern cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com