Hydraulic-motor angular-displacement digital servo control system and method thereof

A digital control, hydraulic motor technology, applied in the field of digital servo control of hydraulic motor angular displacement, to achieve the effect of improving system response capability, improving static and dynamic performance, and high dynamic tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

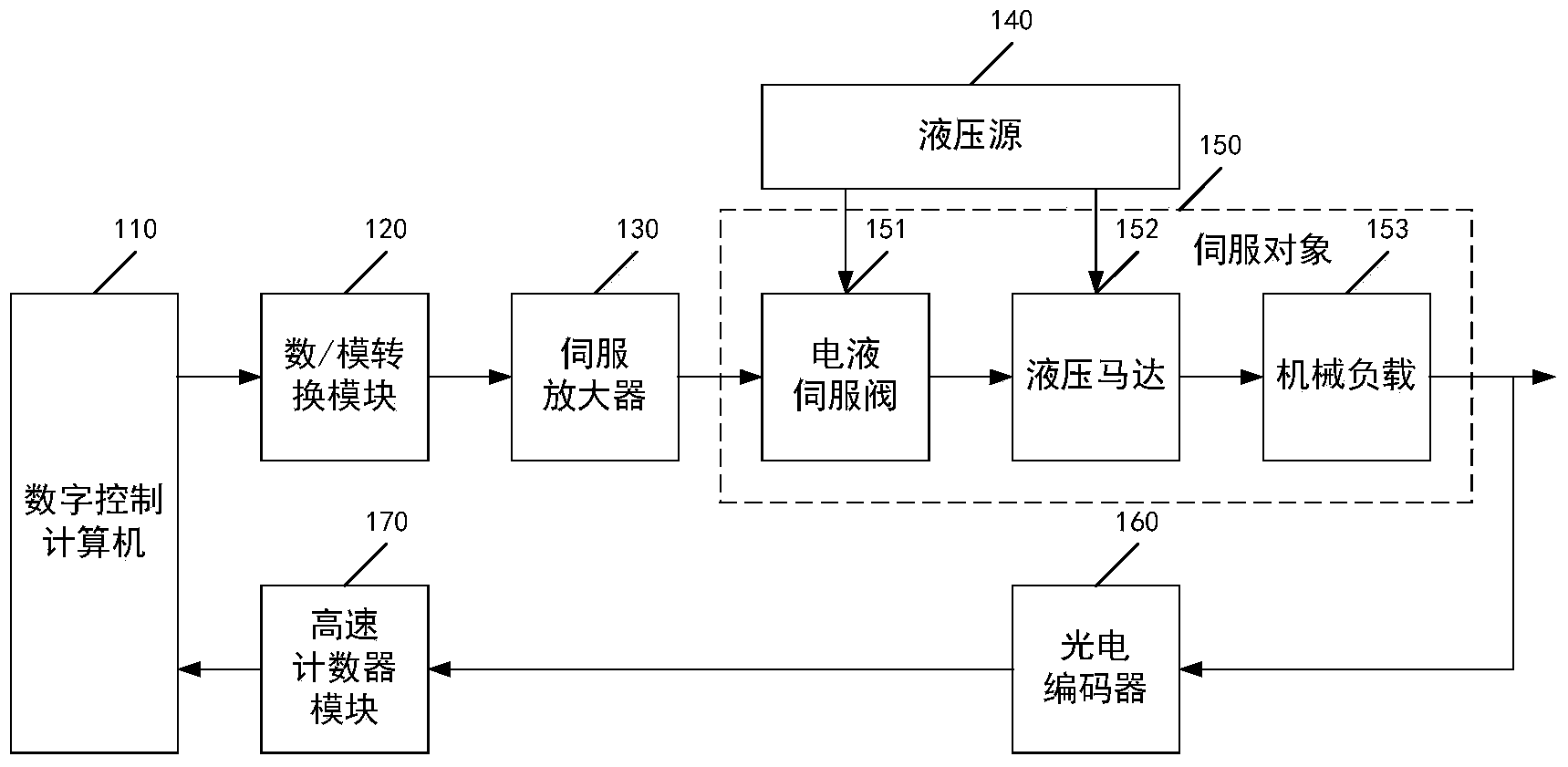

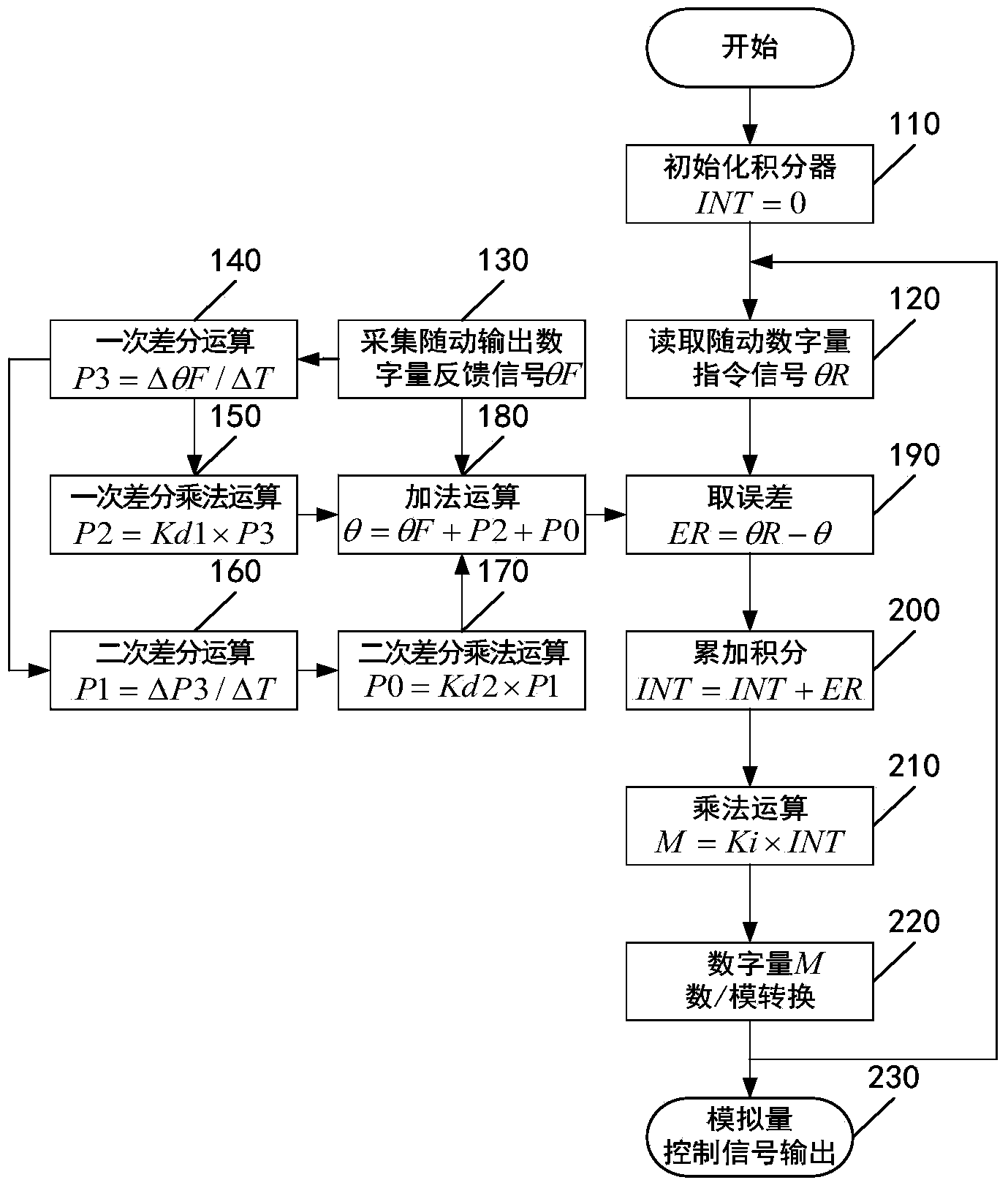

[0035] Such as figure 1 Shown is a block diagram of the hydraulic motor angular displacement digital servo control method according to the embodiment of the present invention. The control method is composed of digital control computer 110, digital / analog conversion module 120, servo amplifier 130, hydraulic source 140, servo object 150, photoelectric encoder 160 and high-speed counting module 170; digital control computer 110, digital / analog conversion module 120 , servo amplifier 130, servo object 150, photoelectric encoder 160 and high-speed counting module 170 are connected circularly in a clockwise direction; wherein the servo object 150 is serially connected in sequence by an electro-hydraulic servo valve 151, a hydraulic motor 152, and a mechanical load 153 , the electro-hydraulic servo valve 151 is also connected to the servo amplifier 130, the mechanical load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com