Dimensionally stable multilayer polyester film

An aromatic polyester, intermediate layer technology, applied in the direction of layered products, synthetic resin layered products, other household appliances, etc., can solve problems such as contradictions, and achieve the effect of high delamination resistance and excellent film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

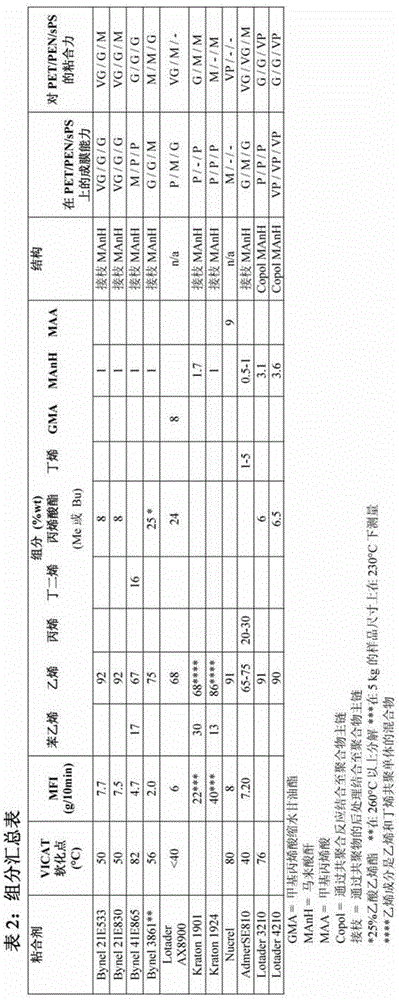

[0142] Films comprising two layers were extruded and cast using a standard melt coextrusion system. The coextrusion system was assembled utilizing two independently operated extruders that fed separate supplies of polymer melt to standard coextrusion blocks or junctions where these streams were connected. Thereafter, the melt is transferred to a simple, flat film extrusion die that allows the melt curtain to be cast and quenched at temperature on a rotating, cold metal cylinder. The first layer comprised PET polyester 1, which was extruded and cast from a common die at a set processing temperature of 275°C. The second coextruded layer comprises material Bynel 21E533 (a similar grade Bynel 21E830 can be used). The Bynel material was processed at an extruder temperature of 260°C and finally cast from a coextrusion die at 275°C. The cast film was collected at a processing speed of about 1.8 m / min and had a width of about 150 mm. The total thickness of the film was about 550 μm...

Embodiment 2 to 10

[0144] In each of these examples, membranes were fabricated as described in Example 1, except that the material Bynel 21E533 was replaced by the following: Bynel 41E865; Bynel 3861; LotaderAX8900; Lotader 3210; Lotader 4210; KratonFG1901X; Lotader grades are supplied by Arkema Chemicals. Kraton grades are supplied by Kraton Polymers. Bynel and Nucrel grades are supplied by E.I. DuPont de Nemours. Admer grades are supplied by Mitsubishi Chemical Company.

Embodiment 11

[0146]Films were fabricated as described in Example 1 except that the aromatic polyester was replaced by PEN Polyester 2. The PEN material was extruded and cast from a common die at a set process temperature of 285°C. A second coextruded layer of Bynel 21E533 was processed at an extruder temperature of 260°C and finally cast from a coextrusion die at 285°C. The cast film was collected under similar conditions as in Example 1 and had similar dimensions, ie a total thickness of 550 μm with a PEN layer of about 400 μm and a Bynel adhesive layer of about 150 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com