Three-dimensional orthogonal nalgrass composite material plate and molding method thereof

A composite material board and molding method technology, applied in the field of composite material manufacturing, can solve the problems of poor mechanical properties, delamination and ring breakage, poor waterproof performance and corrosion resistance, and achieve low cost, increased interlayer bonding force, excellent tensile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: make four-layer epoxy Arundo donax composite material laminated board.

[0021] The steps in this example are as follows:

[0022] (1) Collect 1-year-old fresh and mature reed bamboo for felling, remove the sundries on the reed bamboo stem, and cut into 0.6-meter reed bamboo segments, break the reed bamboo segments, flatten and process them into reed bamboo strips; then The obtained reed bamboo strips are dried to make the water content 8-10%; finally, the dried reed bamboo strips are planed and processed into standardized reed bamboo strips with a thickness of 2 mm.

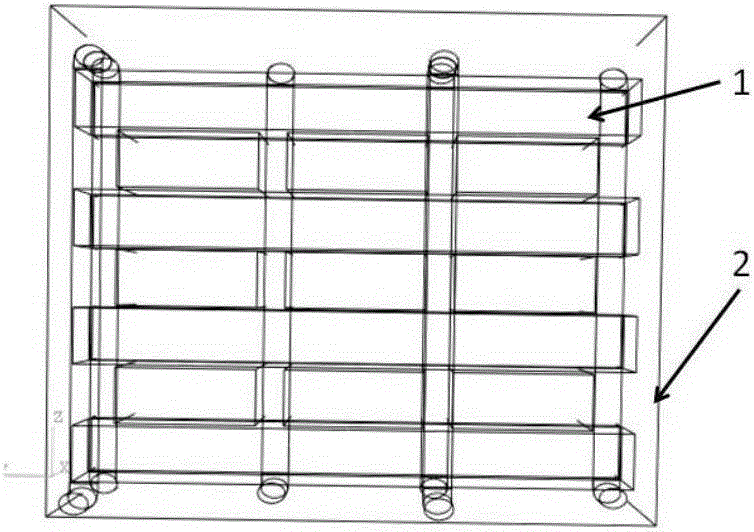

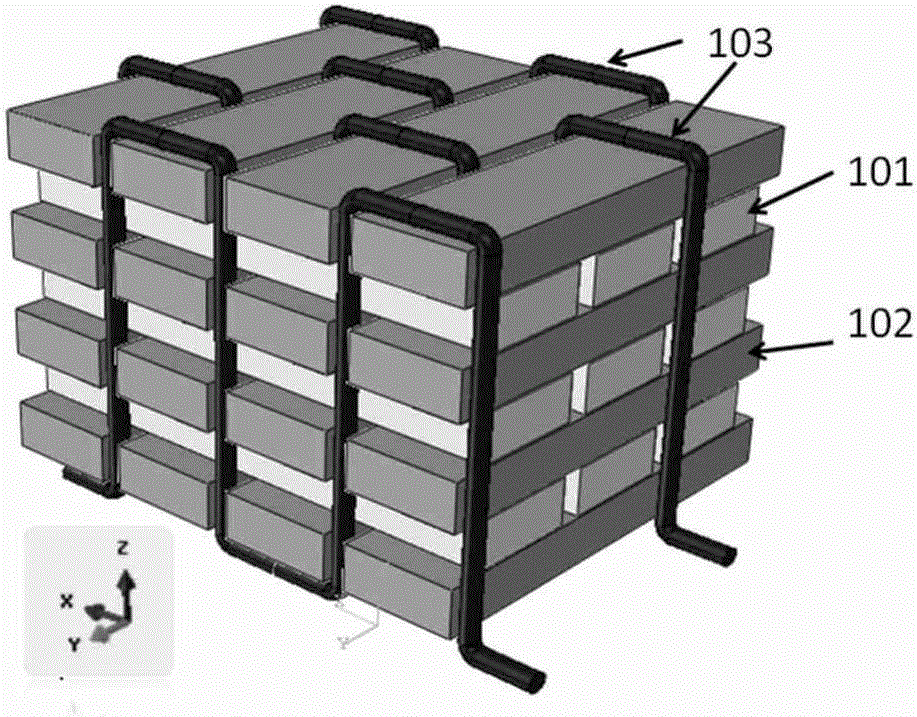

[0023] (2) Lay the flattened reed bamboo board three layers horizontally in the warp direction, and lay four layers in the weft direction, using 1000D Aramid filament yarn as Z-direction yarn with a density of 1.45g / cm 3 , the tensile modulus is 116GPa, and the tensile strength is 200cN / tex. Through the opening of the opening device, the reed bamboo strips arranged orthogonally are bound...

Embodiment 2

[0027] Embodiment 2: making six layers of unsaturated polyester resin Arundo donax composite material laminated board.

[0028] The steps in this example are as follows:

[0029] (1) Collect 1-year-old fresh and mature reed bamboo for felling, remove the sundries on the reed bamboo stem, and cut into 0.8-meter reed bamboo segments, break the reed bamboo segments, flatten and process them into reed bamboo strips; then The obtained reed bamboo strips are dried to make the water content 8-10%; finally, the dried reed bamboo strips are planed and processed into standardized reed bamboo strips with a thickness of 2mm.

[0030] (2) Lay the flattened reed bamboo board 5 layers horizontally in the warp direction, and 6 layers in the weft direction. The yarn in the thickness direction adopts 800D ultra-high molecular weight polyethylene filaments, and the density is 0.97g / cm 3 , which is only 1 / 8 of steel, the tensile modulus is 150GPa, and the tensile strength is 350cN / tex. Pass the ...

Embodiment 3

[0034] Embodiment 3: Making seven layers of phenolic resin Arundo donax composite material laminated board.

[0035] The steps in this example are as follows:

[0036] (1) Collect 1-year-old fresh and mature reed bamboo for felling, remove the sundries on the reed bamboo stem, and cut into 0.6-meter reed bamboo segments, break the reed bamboo segments, flatten and process them into reed bamboo strips; then The obtained reed bamboo strips are dried to make the water content 8-10%; finally, the dried reed bamboo strips are planed and processed into standardized reed bamboo strips with a thickness of 2mm.

[0037](2) 5 layers of flattened reed bamboo boards are laid horizontally in the warp direction, and 6 layers are laid in the weft direction. The yarn in the thickness direction adopts 500D PBO fiber filaments, and the density is 1.54g / cm 3 , the tensile modulus is 180GPa, the tensile strength is 370cN / tex, the yarn is passed through the opening device, and through the opening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com