Multilayer ceramic substrate and manufacturing method thereof

一种多层陶瓷、基板的技术,应用在多层电路制造、制造测量仪器、印刷电路制造等方向,能够解决连接部面积变小、电阻膜与过孔导体连接可靠性下降等问题,达到优异电阻特性、牢固连接强度、小连接面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

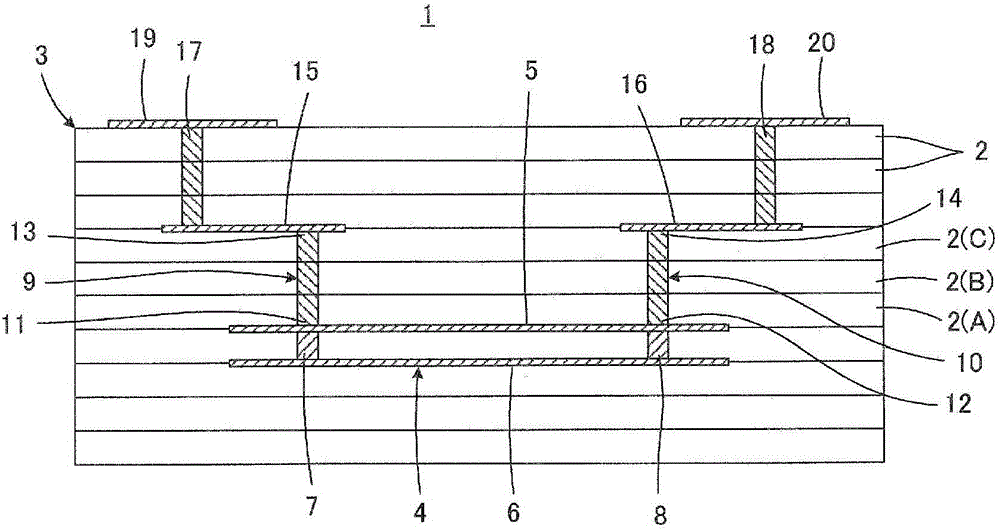

[0049] refer to figure 1 , the multilayer ceramic substrate 1 according to Embodiment 1 of the present invention will be described.

[0050] The multilayer ceramic substrate 1 includes ceramic domains 3 composed of a plurality of laminated ceramic layers 2 . A resistor 4 is arranged inside the ceramic element 3 .

[0051] The resistor body 4 includes a plurality of layers formed between a plurality of ceramic layers 2, for example, two layers of resistance films 5 and 6; and a plurality of, for example, two via conductors for parallel connection arranged at different positions. 7 and 8, the parallel connection via conductors 7 and 8 are used to connect these resistance films 5 and 6 in parallel, and are formed so as to penetrate the ceramic layer 2 in the thickness direction. Via conductors 7 and 8 for parallel connection are preferably made of the same material as resistive films 5 and 6 . Accordingly, it is possible to make it difficult for each component to diffuse betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com