Formula containing enzymatically modified stevia sugar for cool green tea beverage

A technology of green tea beverage and stevia, applied in the field of food and beverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

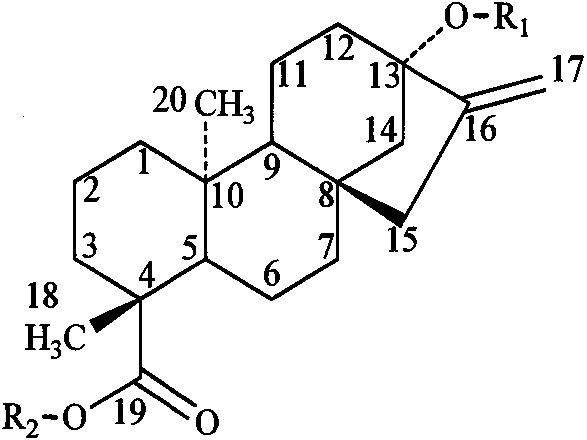

Method used

Image

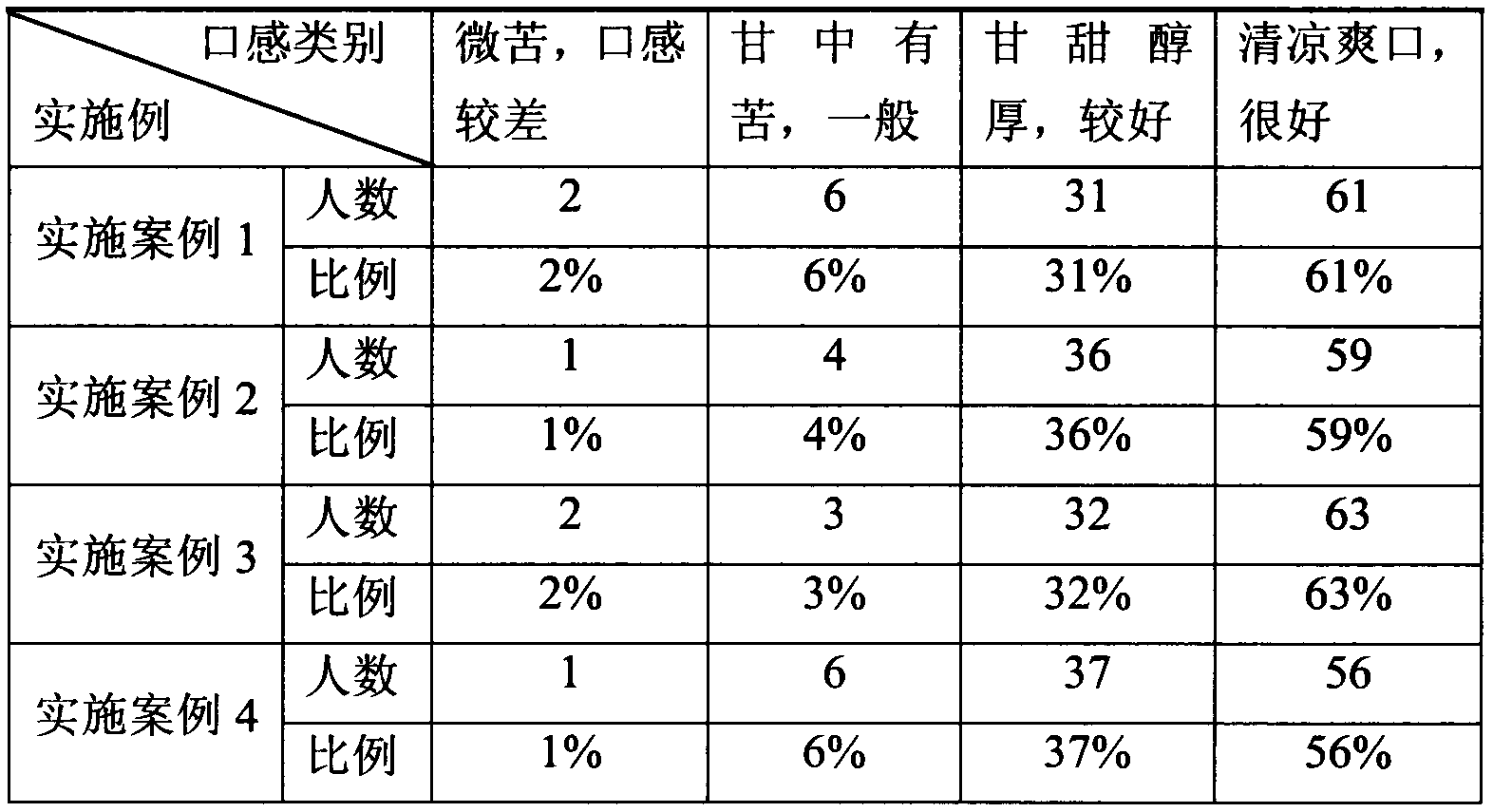

Examples

Embodiment 1

[0017] The weight ratio of raw materials is as follows based on 1000mL of finished beverage: 150g of green tea extract, 0.3g of enzyme-modified stevioside, 4g of natural honey, 0.3g of Vc, 0.2g of sodium D-isoascorbate, and the balance is water.

[0018] Preparation process: (1) Coarse pulverization: chop the tea leaves with a rotary pulverizer, with a particle size of less than 800 μm. If the particle size of the tea leaves is small, the solute in the tea leaves will easily diffuse into the solution, and the inflow and outflow rate of the tea leaves will be high. (2) Sterilization: The sterilization condition is to steam tea leaves at 95°C-100°C for 20-30min. (3) Extraction: Soak the tea leaves in hot water at a ratio of 1:85, and stir slowly. The extraction temperature is 85°C-90°C, and the extraction time is 10 minutes. The extraction method is adopted twice, the extracts are combined, centrifuged, and the leaching residue is discarded. (4) Filtration: Filter the extract s...

Embodiment 2

[0023] The weight ratio of raw materials is as follows based on 1000mL of finished beverage: 200g of green tea extract, 0.8g of enzyme-modified stevioside, 0.2g of natural honey, 0.2g of Vc, 0.1g of sodium D-isoascorbate, and the balance is water.

[0024] The preparation process is the same as that of Example 1.

[0025] Compared with Example 1, increasing the amount of enzyme-modified stevioside increases the sweetness and coolness of the green tea beverage.

Embodiment 3

[0027] The weight ratio of raw materials is as follows based on 1000mL of finished beverage: 200g of green tea extract, 0.5g of enzyme-modified stevioside, 0.4g of natural honey, 0.25g of Vc, 0.15g of sodium D-isoascorbate, and the balance is water.

[0028] The preparation process is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com