Slow cooker

A slow cooker and pot lid technology, which is applied to special materials of cooking utensils, lids of cooking utensils, heating devices, etc., can solve the problem that users cannot control the temperature and cooking time, the heating elements fluctuate greatly, and the heating temperature is not good. Control and other issues, to achieve the effect of various choices, little influence of ambient temperature, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

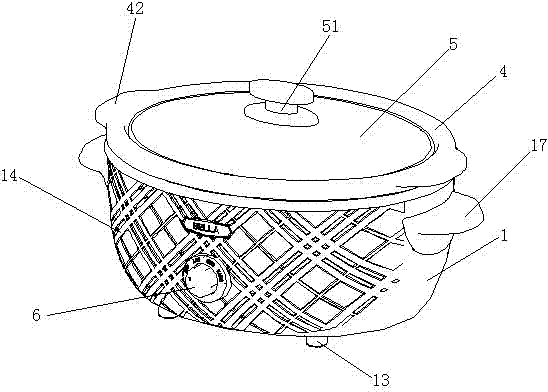

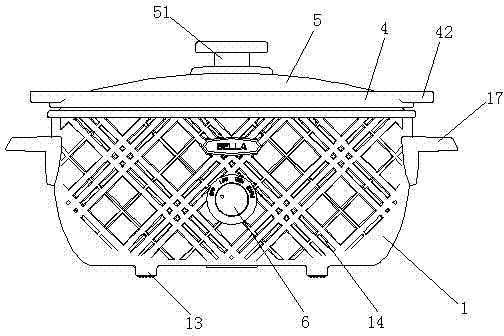

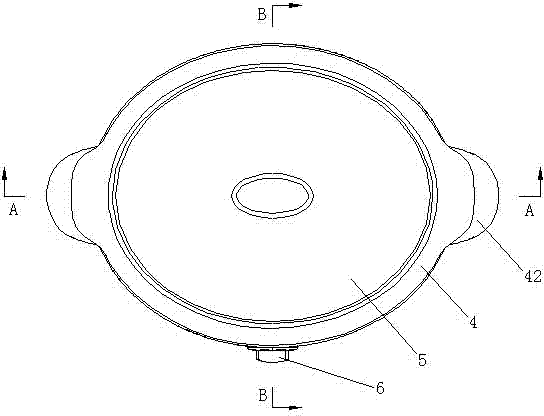

[0029] Figure 1 to Figure 9 Shown is the structural representation of the present invention.

[0030] The reference signs are: pot shell 1, pot cavity 1a, bottom cover 11, cooling hole 11a, shell 12, mounting hole 12a, supporting foot 13, bird's nest pattern 14, screw 15, base screw pad 16, handle 17 , installation reinforcement plate 18, pot aluminum liner 2, heating chamber 2a, boss 21, flange 22, heat insulation ring 3, concave cavity 3a, pot pottery liner 4, support edge 41, lug 42, pot cover 5, Handle part 51, connecting screw 52, handle cover 53, control switch 6, switch body 61, switch panel 62, switch knob 63, mica sheet 64, power cord 7, PTC heater 8, radiator 81, heat conduction plate 82 .

[0031] Such as Figure 1 to Figure 9 as shown,

[0032] A slow cooker, comprising a pot shell 1 provided with a power cord 7, and a contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com