Brazing method for tungsten carbide die punching head and steel base

A technology of cemented carbide and brazing method, applied in the field of mold processing, can solve the problems of stress release, workpiece cracking and scrapping, processing cracking, etc., and achieve the effect of reducing the internal stress of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

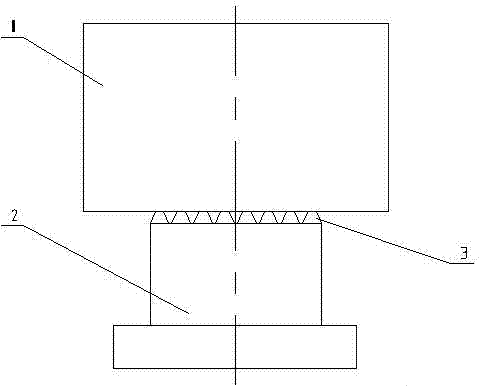

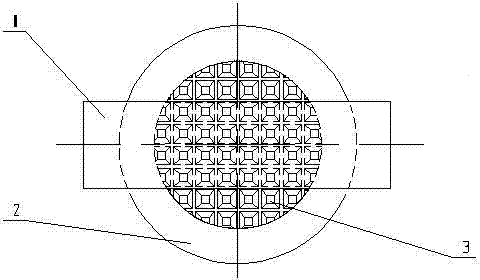

[0024] Example Figure 1-3 Shown: a brazing method of a cemented carbide die stamping head and a steel base, including a cemented carbide die stamping head brazed on the steel base, the specific steps are:

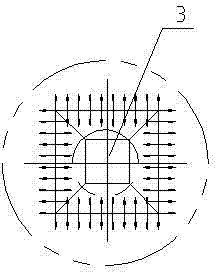

[0025] ① First process and divide the large square brazing surface of the steel base 2 into small pieces 3 of 3mm×3mm that are spaced apart from each other. The grooves between the small pieces 3 are 3mm wide and 2mm deep;

[0026] ② When the cemented carbide die stamping head 1 is brazed to the steel base 2, the heating temperature of the entire workpiece is less than 650°C;

[0027] ③ Control the high-frequency heating area, and place the plane of half the height of the annular heating ring outside the workpiece and the contact plane between the steel base 2 and the cemented carbide die stamping head 1;

[0028] ④ After the brazing is completed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com