Laser beam splitting and processing device

A processing device and laser beam technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of slow processing speed and low processing efficiency, and achieve improved processing efficiency, rich spatial trajectory modulation, and fast focus switching Effect of High Precision Focus Switching Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

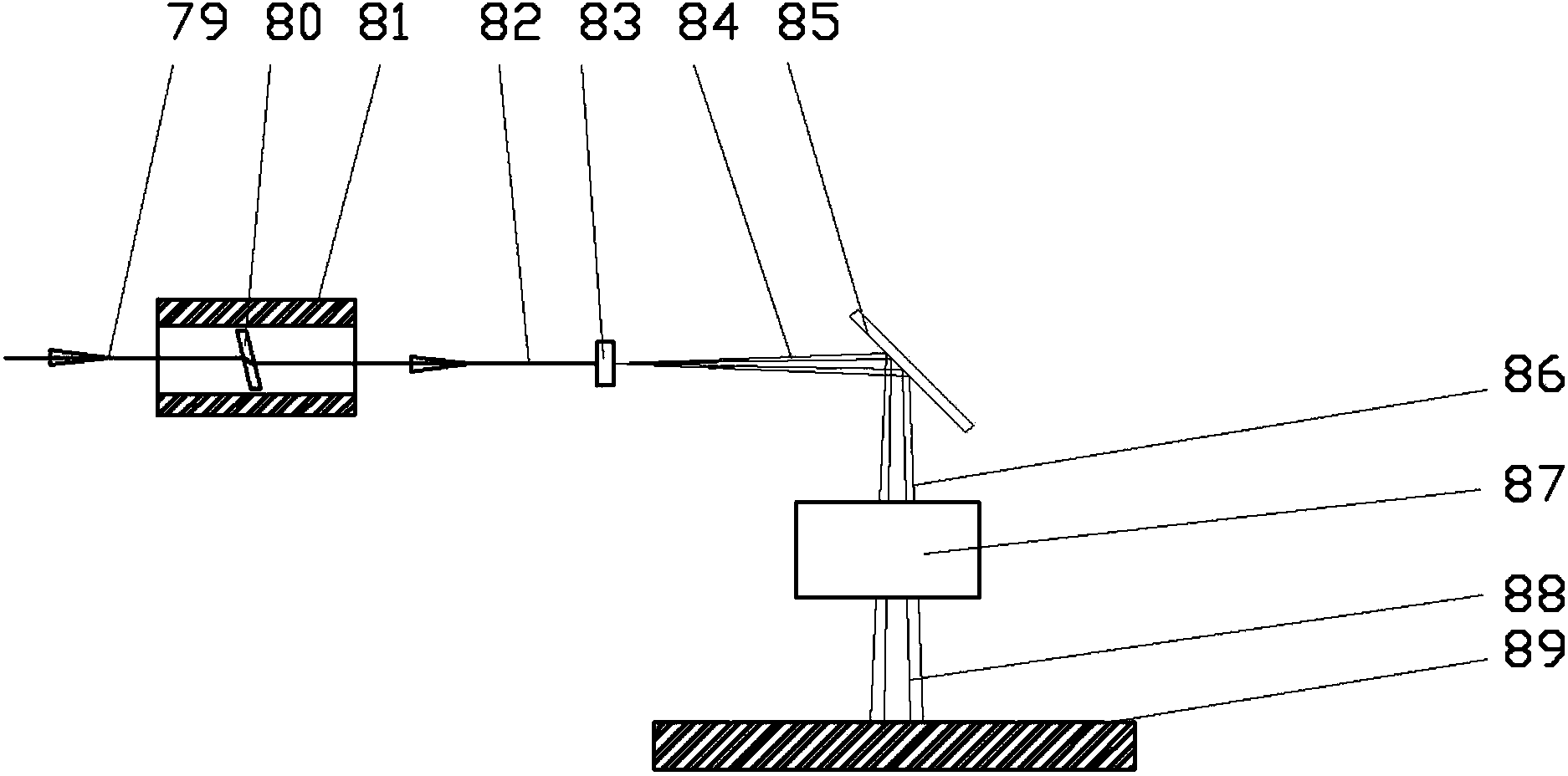

[0049] figure 1 It is a schematic diagram of the structure of a laser beam splitting processing device of the present invention when it is applied in the drilling of alumina ceramics, as figure 1 As shown: including a beam control module, a laser beam splitting module and a laser focus switching module, the workpiece 89 to be processed is a 1000 micron thick aluminum oxide ceramic sheet, which is fixedly installed on a moving platform.

[0050] The beam control module of this embodiment includes a laser beam expansion unit (not shown in the figure) and a beam dynamic control unit.

[0051] The incident beam 79 of this embodiment is a collimated beam with a diameter of 10 millimeters, and its relevant parameters are as follows: laser wavelength 532 nanometers, beam quality factor less than 1.2, spot circularity greater than 90%, average power 35 watts, single-mode Gaussian laser (transverse field strength is Gaussian distribution), pulse repetition frequency 50 kHz.

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com