Preparation method of micro filter screen assembly for aircraft engine oil circuit system

A technology of aircraft engine and oil circuit system, applied in aircraft parts, transportation and packaging, etc., can solve the problems of reduced service life and reliability, stress concentration, large scrap volume, etc. The roundness is easy to ensure and the effect of improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

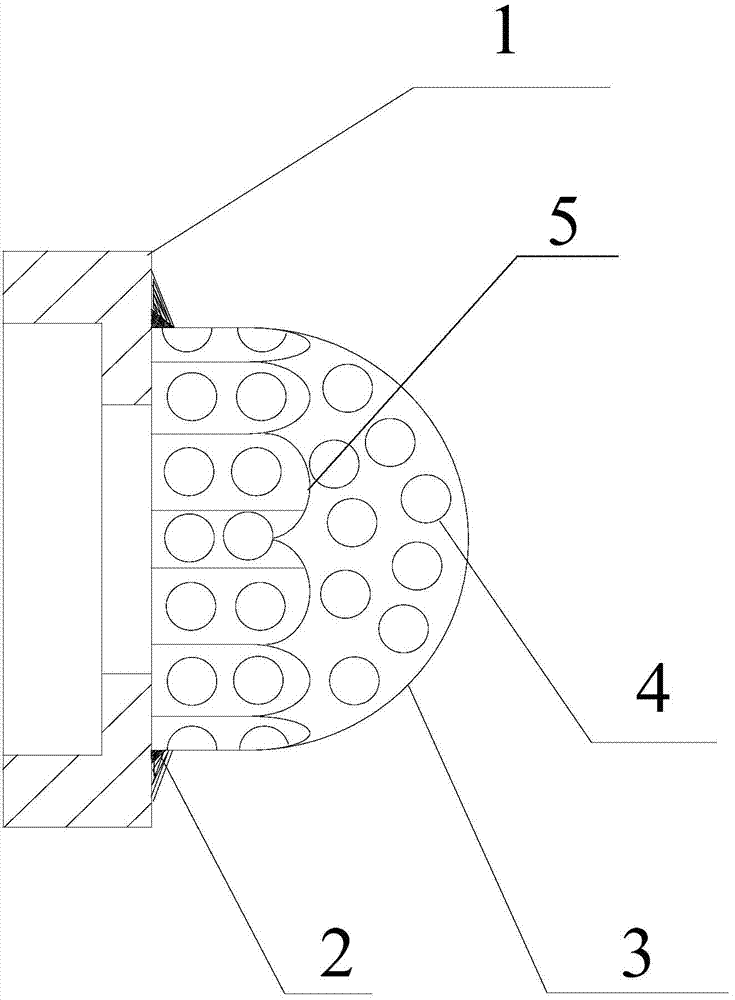

[0019] Attached below Figure 1-2 An embodiment of the present invention is described.

[0020] The preparation method of the micro filter screen assembly for the oil circuit system of the aircraft engine includes the following steps:

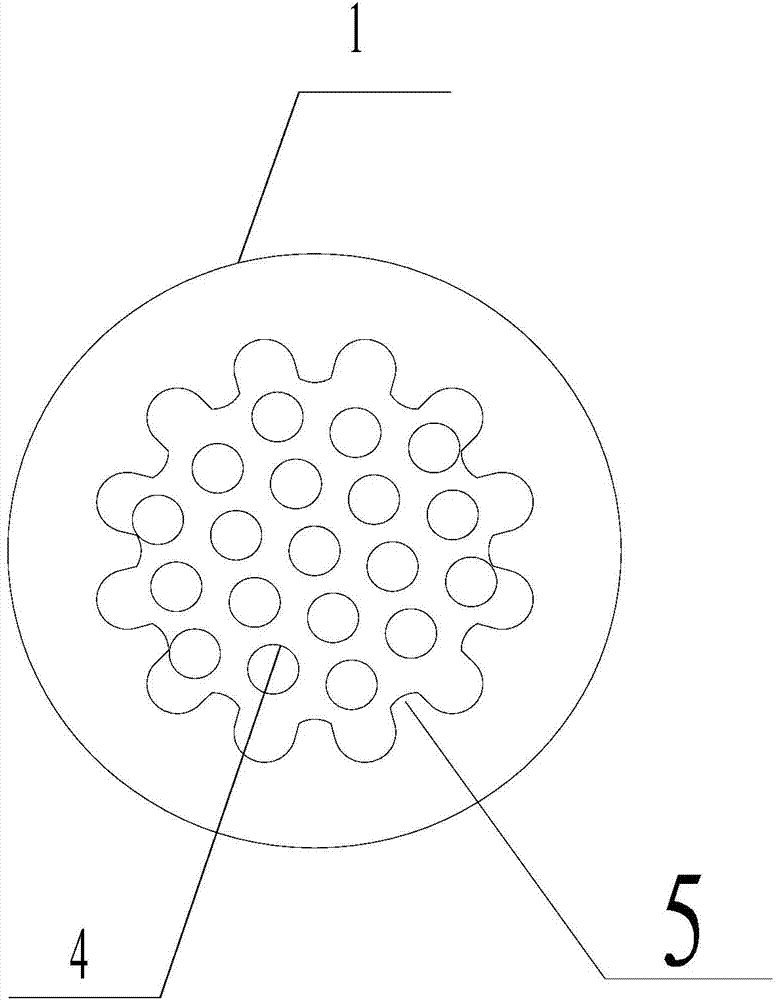

[0021] 1) Stretch forming: take the filter material and punch it into a disc with a certain diameter, and then use a special mold to stretch the disc into a bucket with a certain diameter and height. Use a lathe to flatten the open end of the bucket filter and remove it by hand. For burrs, change another set of special molds to stretch out a plurality of folds 5 along its axis from the open end of the barrel-shaped filter to form a molded filter 3; the number of folds 5 is 3-20;

[0022] 2) Laser drilling: install the barrel-shaped molded filter 3 on a special fixture. Use a laser to make a number of small holes 4 on the hemispherical surface of the sealing end and remove it, and then install the molded filter 3 on a fixture with indexing function ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com