Roll-cutting tool

A hob cutting and tool technology, applied in metal processing and other directions, can solve the problems of self-expansion and poor cutting quality of the hob cutter, and achieve the effects of simple structure, good general performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

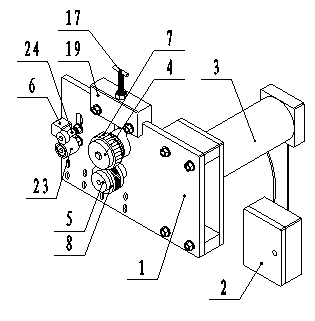

[0029] Example 1: Combining Attachment figure 1 and 2 , a rolling cutting tool, including a frame 1, a control box 2 and a rolling cutting motor 3, a rolling cutting shaft 4, a pressure shaft 5, a die 6 and a spacing adjustment mechanism installed on the frame 1, and the die 6 is fixed on the On one side of the frame 1, the rolling-cutting motor 3 is fixed on the other side of the frame 1, the rolling-cutting motor 3 is connected with the rolling-cutting shaft 4, the wiring of the rolling-cutting motor 3 is connected with the control box 2, and one end of the rolling-cutting shaft 4 is evenly A set of disc-shaped hobbing cutters 7 are provided, and the back of the hobbing cutter 7 is provided with a control mechanism for controlling the expansion and contraction of the hobbing cutter 7. The pressure-receiving wheel 8 matched with the cutter 7, and the spacing adjustment mechanism is linked with the rolling and cutting shaft 4.

[0030] When installing, firstly install the h...

Embodiment 2

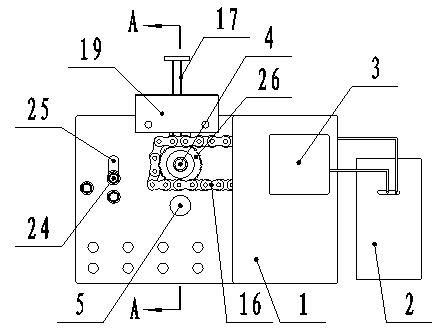

[0031] Example 2: Combining Attachment figure 1 , 2 , 3, 4, 6, a rolling cutting tool, including a frame 1, a control box 2, a rolling cutting motor 3, a rolling cutting shaft 4, a pressure shaft 5, a mold 6, and a spacing adjustment mechanism installed on the frame 1 , the positioning wheel 23 and the positioning bolt 24, the mold 6 is threadedly connected to one side of the frame 1, the hobbing motor 3 is fixed on the other side of the frame 1, and one end of the hobbing shaft 4 is provided with a transmission gear 26, The motor 3 is connected with the transmission gear 26 through the chain 16, the wiring of the hobbing motor 3 is connected with the control box 2, the other end of the hobbing and cutting shaft 4 is evenly provided with a group of disc-shaped hobbing cutters 7, and the back of the hobbing cutter 7 is provided with The control mechanism that controls the expansion and contraction of the hob cutter 7, the control mechanism is composed of a compression spring ...

Embodiment 3

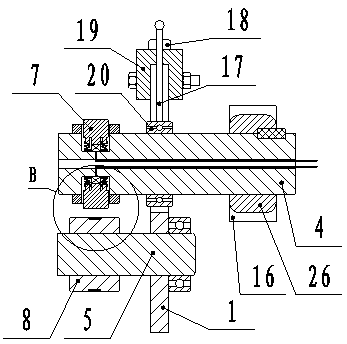

[0033] Embodiment 3, in conjunction with the attached Figure 5 , 6 , 7, 8, 9, a rolling cutting tool, including a frame 1, a control box 2, a rolling cutting motor 3, a rolling cutting shaft 4, a pressure shaft 5, a mold 6, and a spacing adjustment mechanism installed on the frame 1 , the positioning wheel 23 and the positioning bolt 24, the mold 6 is threadedly connected to one side of the frame 1, the hobbing motor 3 is fixed on the other side of the frame 1, and one end of the hobbing shaft 4 is provided with a transmission gear 26, The motor 3 is connected with the transmission gear 26 through the chain 16, the wiring of the hobbing motor 3 is connected with the control box 2, the other end of the hobbing shaft 4 is evenly provided with a group of disc-shaped hobbing cutters 7, and the back of the hobbing cutter 7 is provided with a control The telescopic control mechanism of the hob cutter 7 includes a tension spring 11, an eccentric camshaft 12 and a control motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com