A kind of preparation method of high temperature resistant flame retardant composite material

A flame-retardant composite material and high-temperature-resistant technology, which is applied in chemical instruments and methods, synthetic resin layered products, lamination auxiliary operations, etc., can solve the problem of difficulty in obtaining production technical parameters, failure to meet new requirements, and thin overall materials and other problems, to achieve the effect of green production process, excellent ductility and softness, and reduced unit consumption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

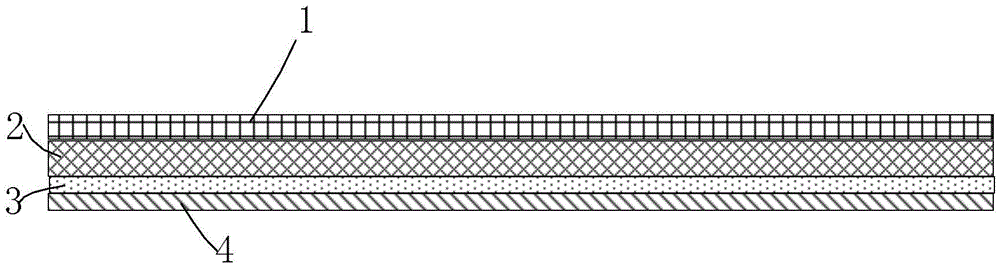

Image

Examples

Embodiment 1

[0022] A method for preparing a high-temperature-resistant flame-retardant composite material, comprising the steps of:

[0023] Step 1, printing patterns on the polyester film according to a predetermined pattern;

[0024] Step 2: apply glue with a dry laminating machine, heat-bond the polyester film with soft polyvinyl chloride cloth under a certain temperature and pressure, and wind it up to obtain an intermediate product with a glue coating amount of 3.2g / m 2 , the thermal lamination temperature is 146°C, the heat sealing pressure is 1.8kg; the winding tension is 19.5N, and the winding speed is 95m / min;

[0025] Step 3, curing the rolled intermediate product at a certain temperature: specifically, curing the intermediate product at a constant temperature of 50° C. for 25 hours.

[0026] Step 4. After the roll film is cooled, use a laminating machine to apply glue and compound it with the paper release film under a certain pressure and wind it up. In this step, the amount ...

Embodiment 2

[0030] A method for preparing a high-temperature-resistant flame-retardant composite material, comprising the steps of:

[0031] Step 1, printing patterns on the polyester film according to a predetermined pattern;

[0032] Step 2: apply glue with a dry laminating machine, heat-bond the polyester film with soft polyvinyl chloride cloth under a certain temperature and pressure, and wind it up to obtain an intermediate product with a glue coating amount of 3.8g / m 2 , the thermal lamination temperature is 152°C, the heat sealing pressure is 2.4kg; the winding tension is 21.5N, and the winding speed is 100m / min;

[0033] Step 3, curing the rolled intermediate product at a certain temperature: specifically, curing the intermediate product at a constant temperature of 55° C. for 28 hours.

[0034] Step 4. After the roll film is cooled, use a laminating machine to apply glue and compound it with the paper release film under a certain pressure and wind it up. In this step, the amount...

Embodiment 3

[0038] A method for preparing a high-temperature-resistant flame-retardant composite material, comprising the steps of:

[0039] Step 1, printing patterns on the polyester film according to a predetermined pattern;

[0040] Step 2: apply glue with a dry laminating machine, heat-bond the polyester film with a soft polyvinyl chloride cloth under a certain temperature and pressure, and wind it up to obtain an intermediate product, and the amount of glue applied is 3.5g / m 2 , the thermal lamination temperature is 150°C, the heat sealing pressure is 2.5kg; the winding tension is 18N, and the winding speed is 105m / min;

[0041] Step 3, curing the rolled intermediate product at a certain temperature: specifically, curing the intermediate product at a constant temperature of 45° C. for 30 hours.

[0042] Step 4. After the roll film is cooled, use a laminating machine to apply glue and compound it with the paper release film under a certain pressure and wind it up. In this step, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com