High-temperature-resistant flame-retardant glue solution and preparation method of automobile air filter paper using glue solution

An air filter paper and flame retardant technology, which is applied in the field of preparation of automobile air filter paper, can solve the problems of reduced air permeability of filter paper, easy moisture absorption deformation of flame retardant filter paper, decreased strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

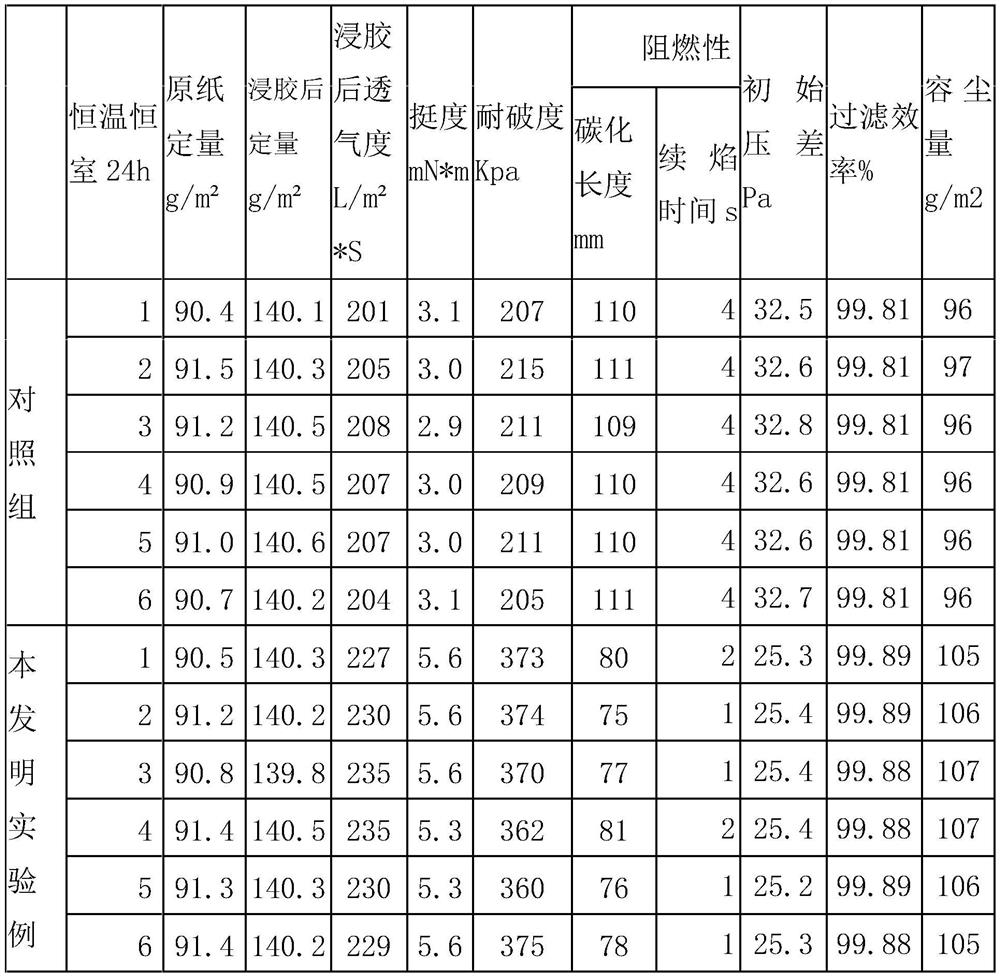

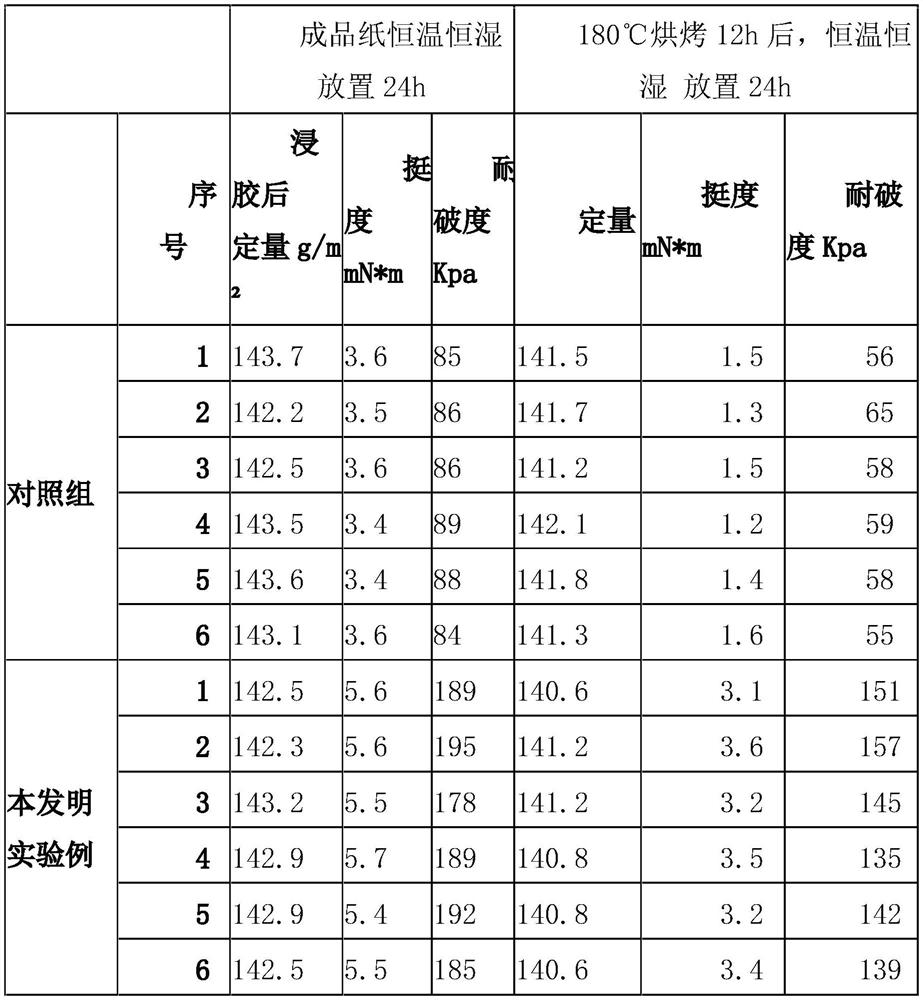

Examples

Embodiment 1

[0027] A kind of glue solution with high temperature resistance and flame retardancy and the preparation method of the automobile air filter paper using the glue solution, the automobile air filter paper comprises the following components according to the mass distribution ratio: acrylic resin 55%, flame retardant A 37.0%, flame retardant A Flame retardant B 3.0%, water resistant agent 5.0%; described flame retardant A is Hycar NH3069 halogen-free flame retardant acrylic emulsion, described flame retardant B is BASFMelapur 200 efficient halogen-free flame retardant, described water resistant agent It is BASF acrylate resin 950aL;

[0028] Its preparation method comprises steps as follows:

[0029] Step (1) Base paper preparation: Weigh mixed fibers composed of mercerized pulp, coniferous pulp fibers, broadleaf pulp fibers, and PET fibers and soak for 45 minutes to disintegrate. In the mixed fibers, 15.0% of mercerized pulp, needle Leaf pulp fiber accounts for 50%, broadleaf p...

Embodiment 2

[0033] With the dip coating glue solution described in embodiment 1, the difference is that raw material components and weight percentages thereof are composed as follows:

[0034] Acrylic resin 55%, flame retardant A 35.0%, flame retardant B 5.0%, water resistant agent 5.0%.

Embodiment 3

[0036] With the dip-coating glue solution described in Example 1, the difference is that the raw material components and their weight percentages are as follows: 55% of acrylic resin, 32.0% of flame retardant A, 8.0% of flame retardant B, and 5.0% of water resistant agent %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com