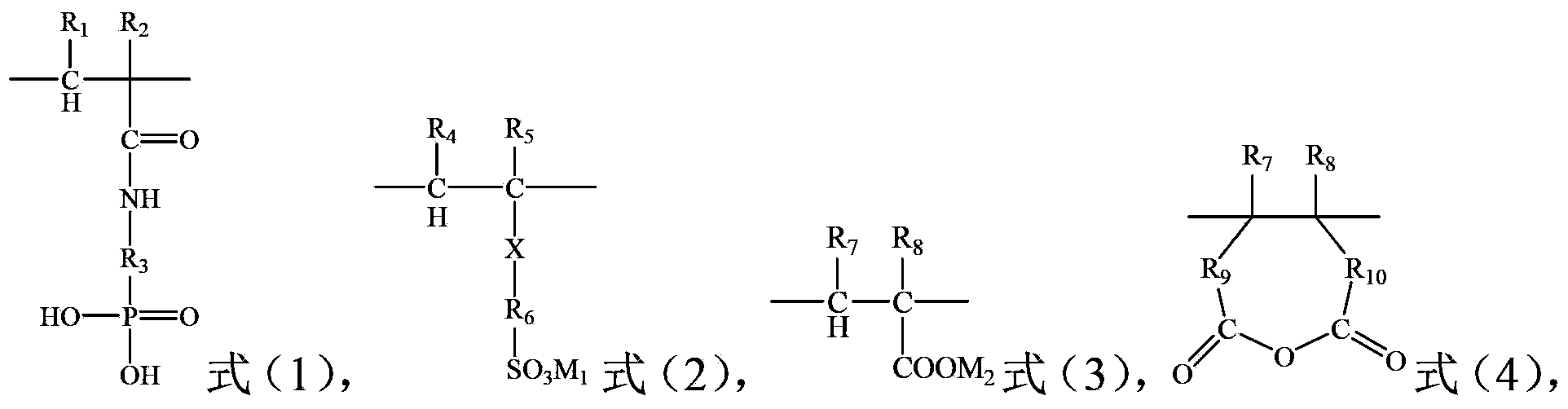

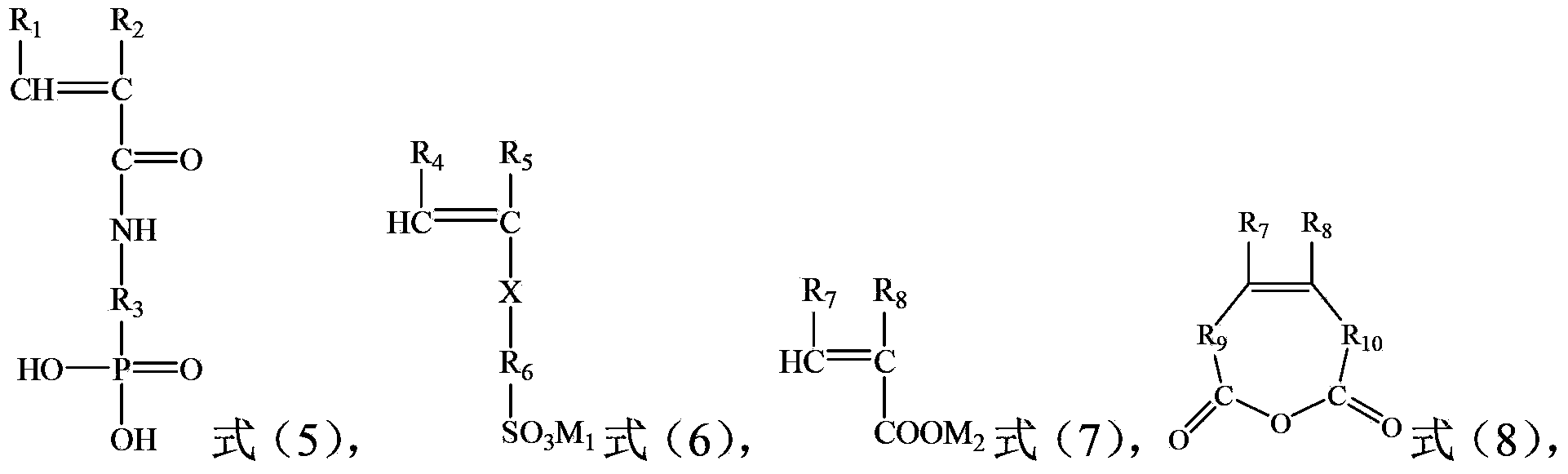

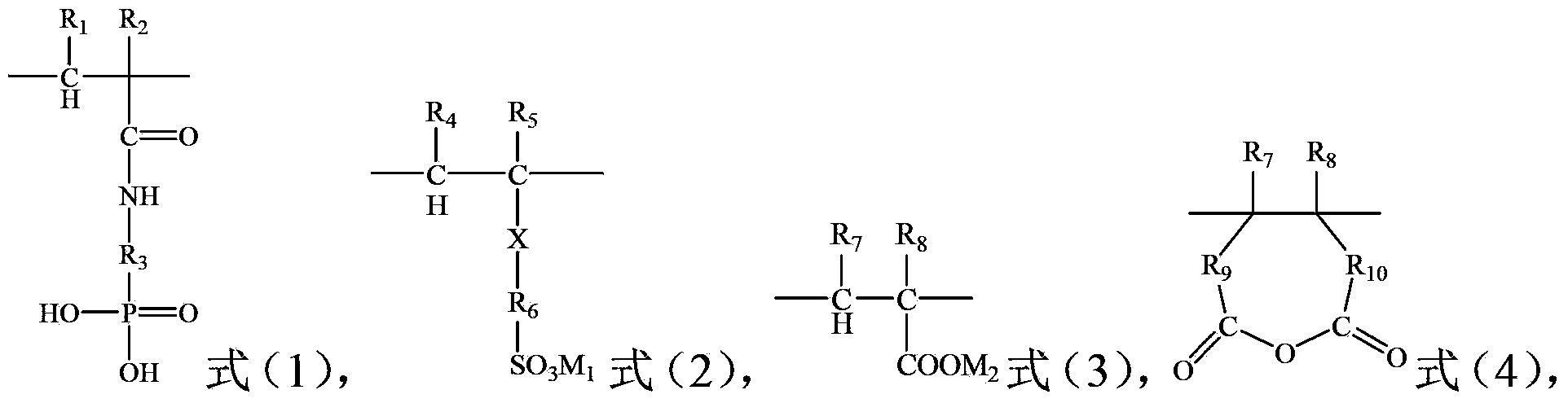

Phosphonic acid base containing polymer and application thereof as well as phosphonic acid base containing polymer drilling fluid viscosity reducer

A polymer, phosphonic acid-based technology, used in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor viscosity reduction effect, and achieve the effect of good temperature resistance and salt resistance, and excellent viscosity reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example is used to illustrate the preparation method of the phosphonic acid group-containing polymer and the phosphonic acid group-containing polymer drilling fluid viscosity reducer provided by the present invention.

[0046] 2-acrylamido-2-methylpropanephosphonic acid (AMPP) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and acrylic acid (AA), according to the material ratio of 85%: 10 %: 5% is mixed and dissolved in water to form a monomer mixture aqueous solution with a mass fraction of 35%, and ammonium persulfate accounting for 3% of the total mass of the monomer mixture is formulated into an aqueous solution with a mass fraction of 10%. 1.5% thioglycolic acid (TGA) of the total mass of the monomer mixture is dissolved in water (the weight of water in which thioglycolic acid is dissolved is twice the total mass of the monomer mixture) and added to the reaction kettle to raise the temperature to 65°C, and then the monomer water mixture solution and ammon...

Embodiment 2-9

[0048] Examples 2-9 are used to illustrate the preparation method of the phosphonic acid group-containing polymer and the phosphonic acid group-containing polymer drilling fluid viscosity reducer provided by the present invention.

[0049] Prepare phosphonic acid-based polymer and phosphonic acid-based polymer drilling fluid viscosity reducer according to the method of Example 1. The difference is that the number average molecular weight Mn of the specific reaction substance, reaction conditions and the drilling fluid viscosity reducer obtained is as follows Table 1 shows:

[0050] Table 1

[0051]

[0052] Note: In Table 1, the amount of initiator and molecular weight regulator refers to the percentage of total monomer mass, for example, in Example 1, "ammonium persulfate, 3.5%" means that the initiator is ammonium persulfate, and The amount of ammonium persulfate accounts for 3.5% of the total mass of the monomers; "IPA, 4%" means that the molecular weight regulator is I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com