High-impact resistance polycarbonate composite material and preparation method for same

A polycarbonate and composite material technology, applied in the field of high-impact polycarbonate composite materials and their preparation, can solve the problems of difficulty in applying high-impact properties, poor compatibility, and difficulty in processing ultra-high molecular weight polyethylene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

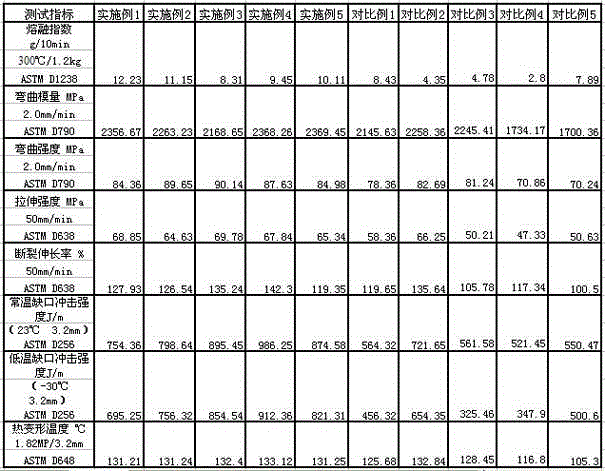

Examples

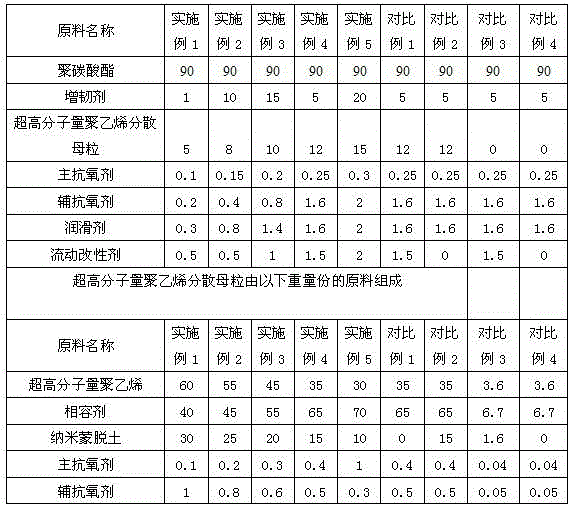

Embodiment 1

[0065] A kind of preparation method of high-impact polycarbonate composite material, it is characterized in that: comprise following preparation steps:

[0066] The first step: preparing ultra-high molecular weight polyethylene dispersion masterbatch, including the following steps:

[0067] Step 1: Weigh 60 parts of ultra-high molecular weight polyethylene, 40 parts of polyethylene grafted maleic anhydride, 30 parts of nano-montmorillonite, 0.1 part of primary antioxidant 1076, and 1 part of secondary antioxidant 168, and put them into Mix in a mixer for 20 minutes;

[0068] Step 2: The raw materials mixed in step 1 are put into a twin-screw extruder, and melted and extruded to obtain an ultra-high molecular weight polyethylene dispersion masterbatch.

[0069] Among them, the temperature of each temperature control zone of the twin-screw extruder is 230°C for temperature control zone 1-2, 260°C for temperature control zone 3-4, and 270°C for temperature control zone 5-6. The...

Embodiment 2

[0075] The first step: preparing ultra-high molecular weight polyethylene dispersion masterbatch, including the following steps:

[0076] Step 1: Weigh 55 parts of ultra-high molecular weight polyethylene, 45 parts of high-density polyethylene grafted maleic anhydride, 25 parts of nano-montmorillonite, 0.2 part of primary antioxidant 1010, 0.8 part of secondary antioxidant 626, Put into the mixer and mix for 25 minutes;

[0077] Step 2: The raw materials mixed in step 1 are put into a twin-screw extruder, and melted and extruded to obtain an ultra-high molecular weight polyethylene dispersion masterbatch.

[0078] Among them, the temperature of each temperature control zone of the twin-screw extruder, the temperature of the temperature control zone 1-2 is 240°C, the temperature of the temperature control zone 3-4 is 240°C, the temperature of the temperature control zone 5-6 is 280°C, the temperature control The temperature in zone 7-8 is 280°C, and the temperature in zone 9-1...

Embodiment 3

[0084] A kind of preparation method of high-impact polycarbonate composite material, it is characterized in that: comprise following preparation steps:

[0085] The first step: preparing ultra-high molecular weight polyethylene dispersion masterbatch, including the following steps:

[0086] Step 1: Weigh 45 parts of ultra-high molecular weight polyethylene, 55 parts of polypropylene grafted maleic anhydride, 20 parts of nano-montmorillonite, 0.3 part of primary antioxidant 1076, 0.6 part of secondary antioxidant PEPQ and 0.4 part Bis(3,5-di-tert-butyl-4-hydroxyphenylpropionyl) hydrazide was put into the mixer and mixed for 30 minutes;

[0087] Step 2: The raw materials mixed in step 1 are put into a twin-screw extruder, and melted and extruded to obtain an ultra-high molecular weight polyethylene dispersion masterbatch.

[0088] Among them, the temperature of each temperature control zone of the twin-screw extruder is 260°C for temperature control zone 1-2, 250°C for temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com