Parching system for processing tea-seed oil

A tea seed oil roasting and frying technology, which is applied in the field of tea seed oil processing roasting system, can solve the problems of low roasting efficiency, unstable roasting temperature control, and large manual roasting workload, so as to improve the roasting efficiency. Efficiency, improvement of product quality, effect of effective temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below according to the drawings and embodiments.

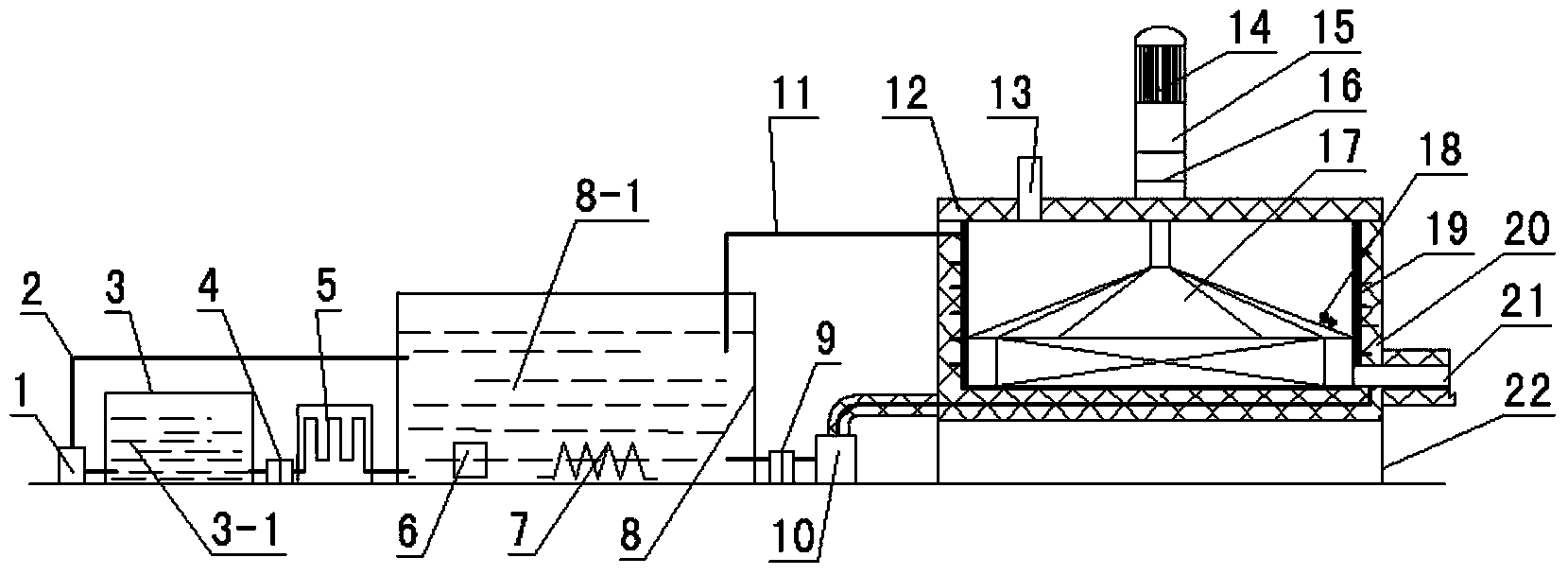

[0016] figure 1 For the structural diagram of the roasting and frying system used for tea seed oil processing in this implementation case, refer to figure 1 , the present invention, the frying system that is used for tea seed oil processing comprises oil supply device, frying device;

[0017] The above-mentioned frying device includes a furnace body 12 , an inner container 19 , a motor 14 , an agitator 17 , a furnace body insulation layer 20 , a speed reducer 15 and an electromagnetic clutch 16 .

[0018] Above-mentioned liner 19 is arranged on the inside of above-mentioned furnace body 12, and above-mentioned furnace body 12 and the top of liner 19 are provided with corresponding through-hole and arrange feed pipe 13, and raw material 18 enters through feed pipe 13, and above-mentioned furnace body 12 and interior The bottom of the liner 19 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com