Utilize acrylonitrile and vinyl acetate to prepare the method for anti-pilling acrylic fiber

A vinyl acetate, anti-pilling acrylic technology, applied in the direction of chemical characteristics of fibers, wet spinning, rayon manufacturing, etc., can solve the problems of inconvenient operation, not obvious improvement of anti-pilling effect, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment, but should not limit protection scope of the present invention with this.

[0017] A kind of method utilizing acrylonitrile and vinyl acetate to prepare anti-pilling acrylic fiber, comprises steps as follows:

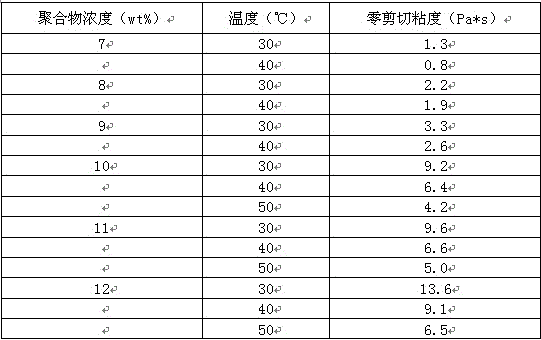

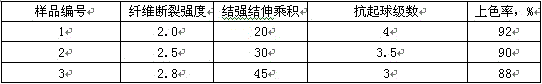

[0018] ① Dissolve acrylonitrile content of 85% to 95% and vinyl acetate content of 5% to 10% with a 40% to 60% NaSCN solution, more precisely, a NaSCN solution with a concentration of 50% to 60% through a high-speed dissolving machine. %, the content of sodium methacrylic sulfonate is less than 1%, and the viscosity-average molecular weight of polyacrylonitrile is 45,000 to 65,000 polyacrylonitrile polymers. In order to ensure a better dissolution effect, the sodium thiocyanate solvent needs to be heated above 75°C. The main function of vinyl acetate is to reduce the chain regularity of polymers, reduce molecular rigidity, and increase fiber feel. The function of sodium methac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com