A kind of anti-pilling antibacterial wool yarn and preparation method thereof

A wool yarn and anti-pilling technology, which is applied in yarn, rayon manufacturing, filament/thread forming, etc., can solve the problem that the goodness of anti-pilling performance and antibacterial performance cannot be satisfied at the same time, and the preparation method of wool fabric is complicated , unable to carry out fully automatic production and other problems, to achieve the effect of good mechanical properties, good antibacterial performance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

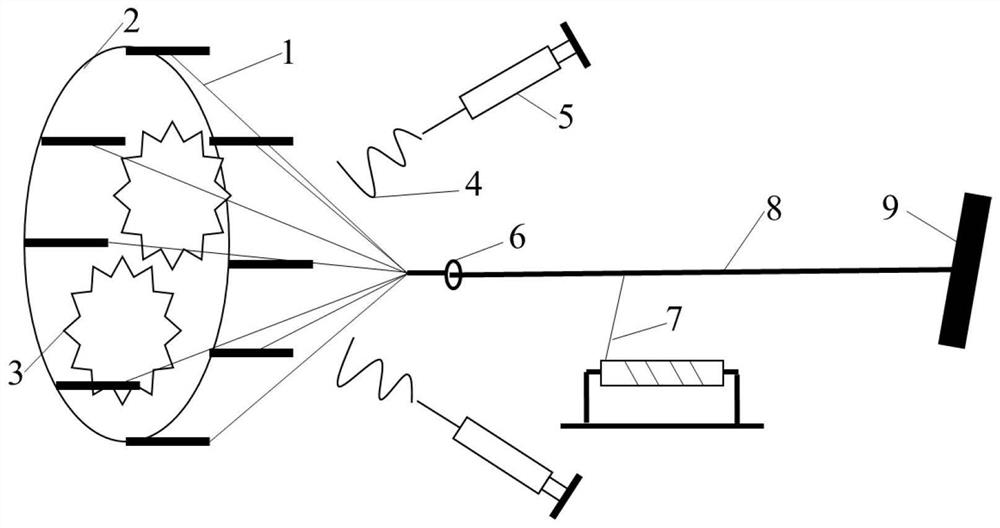

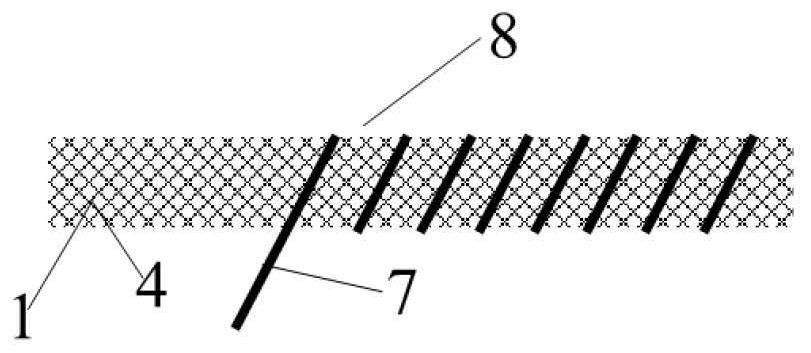

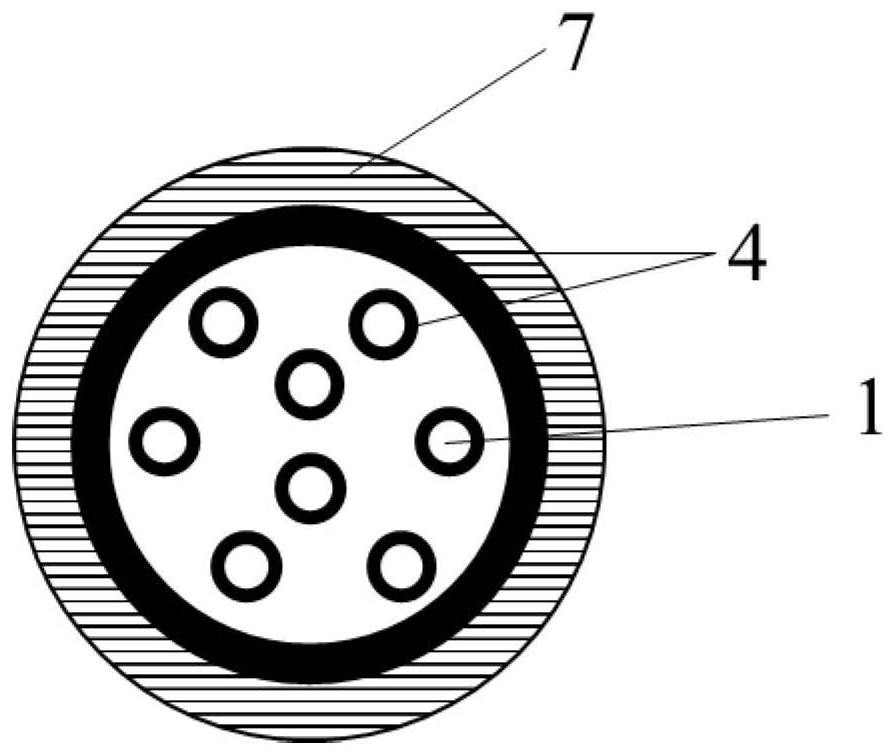

[0032] This embodiment provides an anti-pilling and antibacterial wool yarn, the structure is as follows figure 2 shown, the cross section is as image 3 shown, including a core layer, antibacterial nanofiber layer, and cladding layer. Among them, the core layer is 8 wool yarns 1 (W, the official moisture regain is 15%, the fineness is 20μm, and the length is 50mm), and the product specification is 26s / 2; the antibacterial nanofiber layer is silver-loaded polyacrylonitrile / titanium dioxide nanofiber layer Composite fiber; the covering layer is 1 piece of modal yarn 7 (MD, the official moisture regain is 12%), and the fineness is 32s.

[0033] The preparation method of above-mentioned anti-pilling antibacterial wool yarn comprises the following steps:

[0034] (1) the wool yarn 1 and the modal yarn 7 are respectively carried out to normal temperature drying;

[0035] (2) Add polyacrylonitrile to N,N-dimethylformamide, after stirring evenly, add silver nitrate and titanium d...

Embodiment 2

[0039] This embodiment provides an anti-pilling and antibacterial wool yarn with a cross section such as Figure 4 shown, including a core layer, antibacterial nanofiber layer, and cladding layer. Among them, the core layer is 12 wool yarns 1 (W, the official moisture regain is 15%, the fineness is 20μm, and the length is 50mm), and the product specification is 26s / 2; the antibacterial nanofiber layer is silver-loaded polyacrylonitrile / titanium dioxide nanofiber. Composite fiber; the covering layer is 1 piece of modal yarn 7 (MD, the official moisture regain is 12%), and the fineness is 32s.

[0040] The preparation method of above-mentioned anti-pilling antibacterial wool yarn comprises the following steps:

[0041] (1) the wool yarn 1 and the modal yarn 7 are respectively carried out to normal temperature drying;

[0042] (2) Add polyacrylonitrile to N,N-dimethylformamide, stir evenly, add silver nitrate and titanium dioxide to prepare a mixed solution, and then stir on a ...

Embodiment 3

[0046] This embodiment provides an anti-pilling and antibacterial wool yarn with a cross section such as Figure 4 shown, including a core layer, antibacterial nanofiber layer, and cladding layer. Among them, the core layer is 12 wool yarns 1 (W, the official moisture regain is 15%, the fineness is 20μm, and the length is 50mm), and the product specification is 26s / 2; the antibacterial nanofiber layer is silver-loaded polyacrylonitrile / titanium dioxide nanofiber. Composite fiber; the covering layer is 1 piece of modal yarn 7 (MD, the official moisture regain is 12%), and the fineness is 32s.

[0047] The preparation method of above-mentioned anti-pilling antibacterial wool yarn comprises the following steps:

[0048] (1) the wool yarn 1 and the modal yarn 7 are respectively carried out to normal temperature drying;

[0049] (2) Add polyacrylonitrile to N,N-dimethylformamide, stir evenly, add silver nitrate and titanium dioxide to prepare a mixed solution, and then stir on a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com