Three-layer series micro-perforated pipe muffler

A micro-perforation and muffler technology, which is applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of reduced sound-absorbing materials for mufflers, adverse effects on personnel health, and large volume of mufflers, achieving small back pressure loss and volume reduction The effect of small and wide anechoic frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

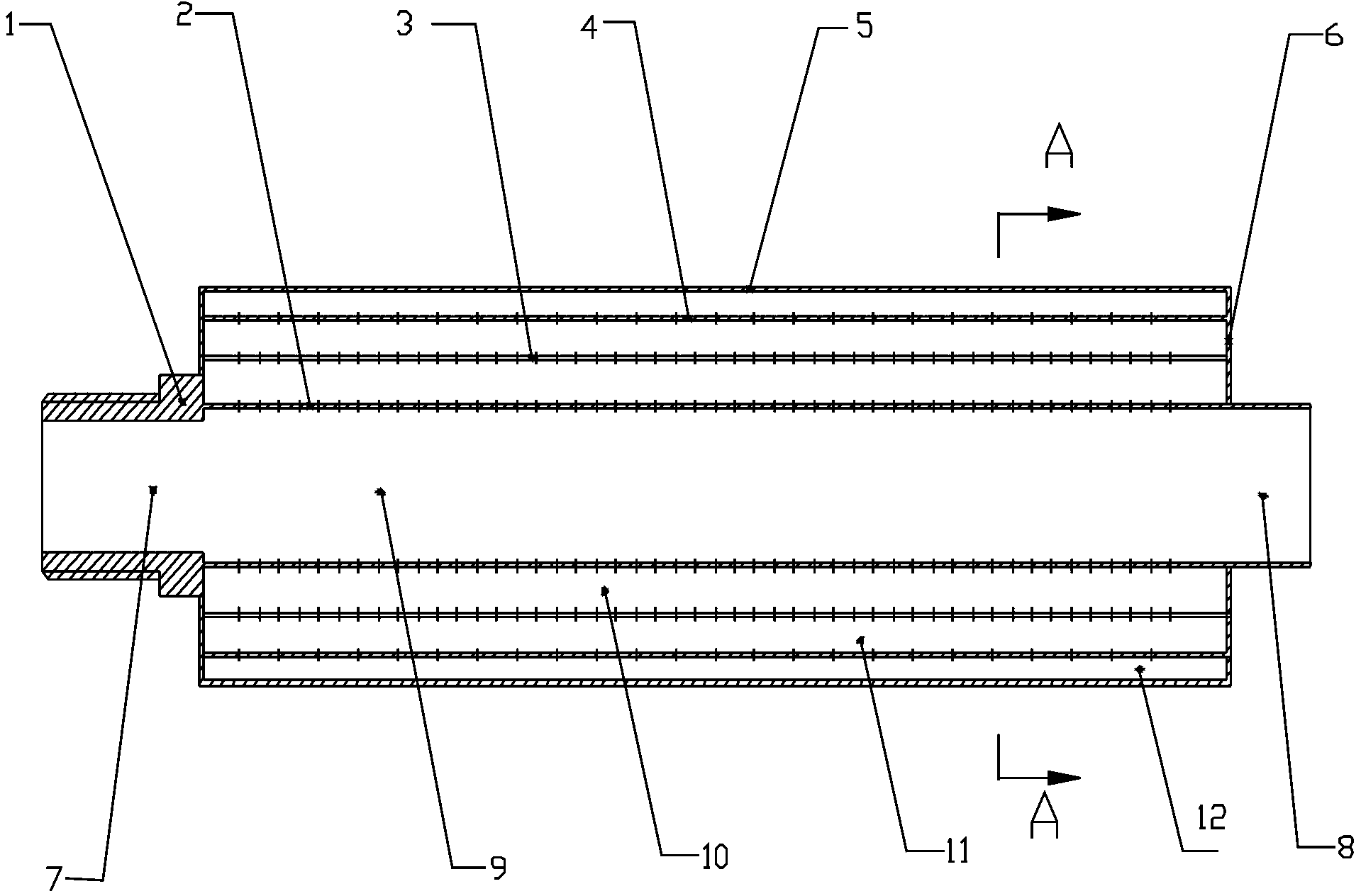

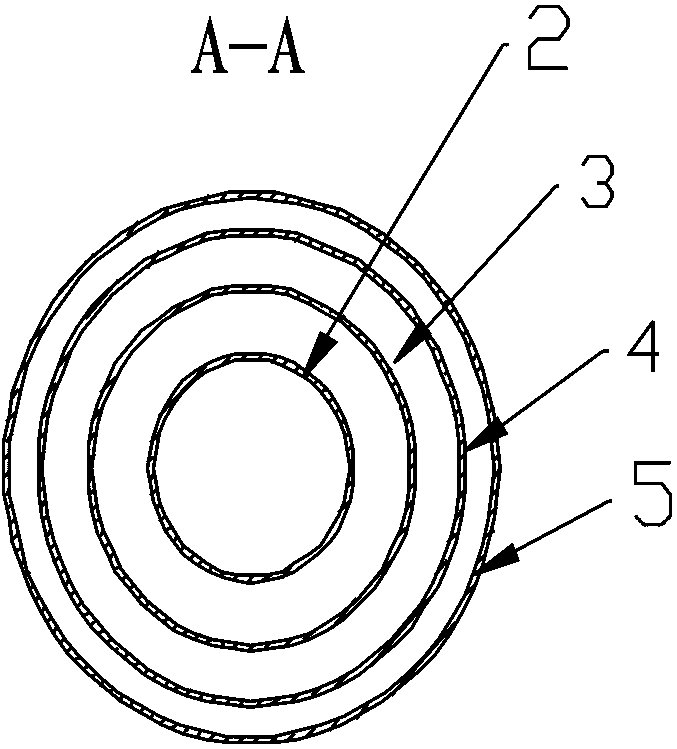

[0023] Such as Figure 1-5 The three-layer micro-perforated tube muffler in series of the present invention includes a metal shell 5, the two ends of the shell 5 are respectively a front end cover 1 and a rear end cover 6, the cross section of the muffler is circular, and the cross section is micro-perforated from the inside to the outside. Hole inner pipe 2, microporous middle pipe 3, microporous outer pipe 4, muffler shell 5.

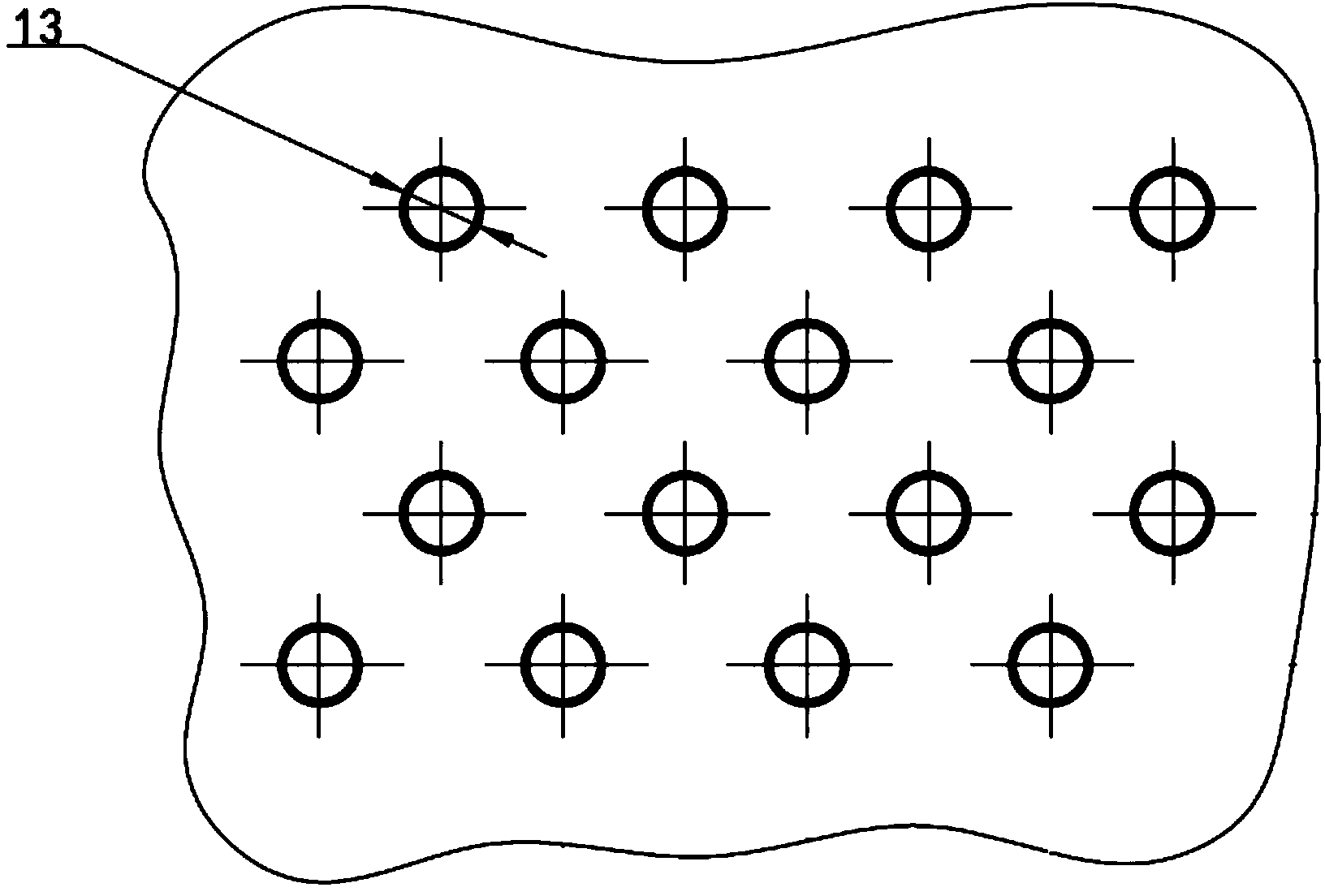

[0024] The muffler shell 5 is cylindrical; the air intake end and the exhaust end are directly connected through the muffler shell, and the air intake end and the exhaust end are located at the center of the two ends of the cylinder; The three-layer micro-perforated tube divides the inner space of the shell into flow channel I9, cavity II10, cavity III11, and cavity IV12; the three-layer micro-perforated tube is cylindrical, and the micro-porous inner tube 2 is connected The air end 7 and the exhaust end 8 have the same diameter, and are directly con...

Embodiment 2

[0027] with Example 1 figure 1 and Figure 3-5 Basically the same, the difference is that the cross section of the muffler shell 5 is square, the cross section of the microporous outer tube 4 is square, the cross section of the microporous inner tube 3 is square, and the cross section of the microporous inner tube 2 is circular.

[0028] In other embodiments not listed in the present invention, the cross-sectional shape of the muffler shell 5, the microporous outer tube 4, and the microporous inner tube 3 can also be changed to an isosceles polygon, such as a rhombus or a pentagon.

[0029] In the above-mentioned embodiment, when the three-layer micro-perforated tube muffler in series of the present invention is working, the airflow flows in from the air inlet 7 on the front cover 1, flows through the shell 5 and the three-layer series micro-perforated tubes 2, 3, 4, and passes through three The layer of micro-perforated pipe is discharged from the exhaust port 8 on the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com