Load-sensitive electric proportional multi-loop valve

A load-sensing, multi-way valve technology, applied in the direction of servo meter circuit, lifting device, fluid pressure actuating device, etc., can solve the problems of large commutation impact, low cost, poor control performance, etc., and achieve improved control accuracy and reduced The effect of streamlining pipeline connections and reducing leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

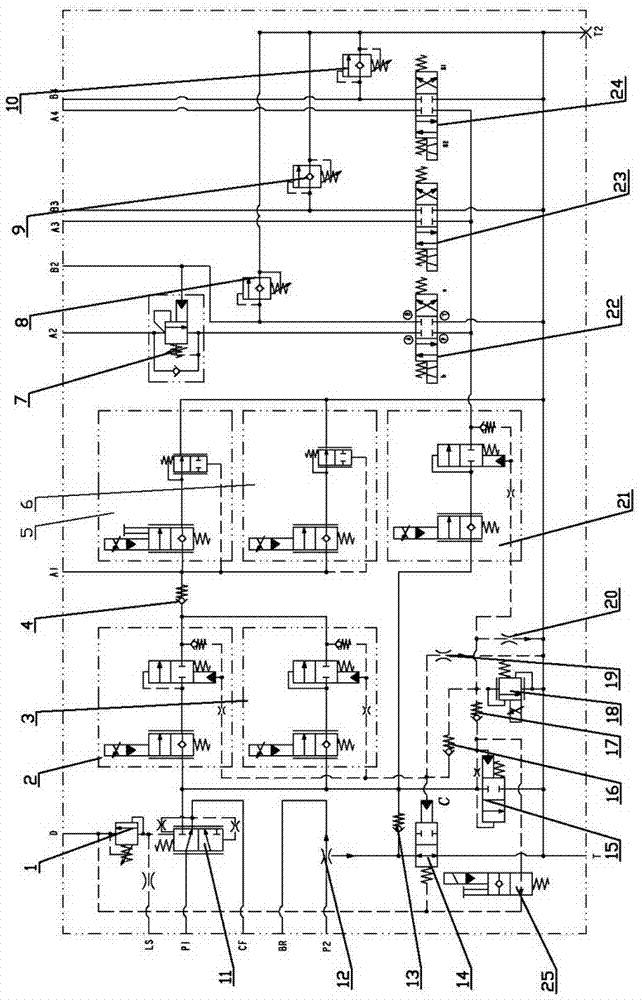

[0013] like figure 1 As shown, this embodiment includes a dynamic load sensing pressure compensation valve 11, a safety valve I1 and a pressure compensation flow regulating valve I12; wherein the oil inlet of the dynamic load sensing pressure compensation valve 11 is connected to the gear pump P1, and an oil outlet is connected to the steering gear The other oil outlet is connected to the main oil circuit of the multi-way valve, and the LS signal oil port of the compensation valve is connected with the steering gear LS port and the oil inlet of safety valve I1 at the same time, and the oil outlet of safety valve I1 is connected with the oil return port D is connected; on the one hand, the main oil road is connected with a lifting circuit and a hydraulic one-way valve I4 in sequence, and the outlet of the hydraulic one-way valve I is respectively connected with the lifting oil port A1 and the descending circuit connected with the oil outlet and the oil return port T On the one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com