Cryogenic top entry type fireproof ball valve with composite heat dissipation disc valve cover

A technology of heat dissipation plate and valve cover, which is applied to the heating/cooling device of the valve, valve device, valve details, etc., can solve the problems of insufficient fireproof sealing ring setting, uncontrollable discharge direction, and increase of the majority factor. , to achieve the effect of eliminating fire hazards, preventing freezing and bonding, and improving the effect of heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

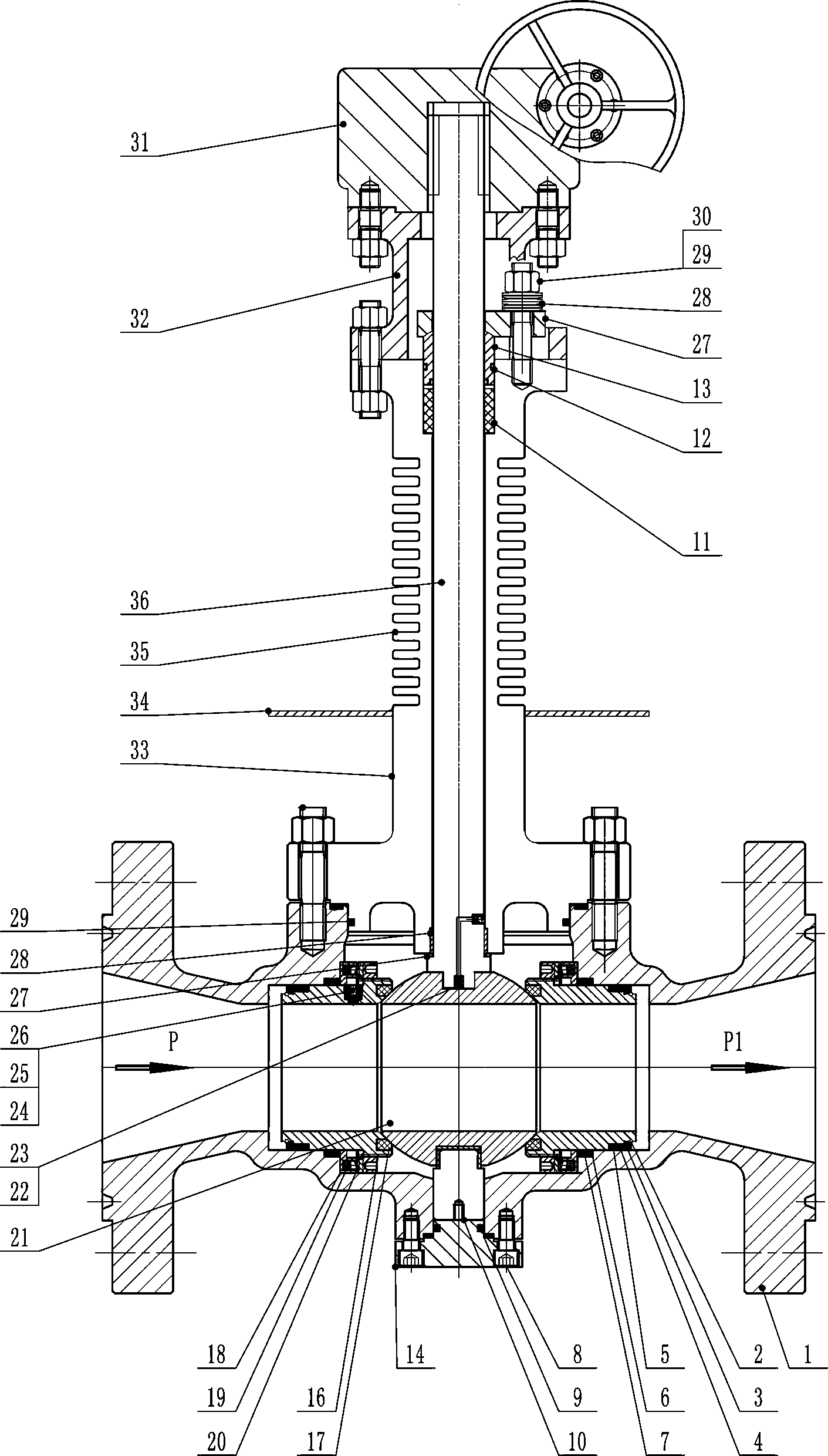

[0023] The structure of the present invention is as figure 1 Shown: Refer to the accompanying drawings, a cryogenic top-mounted fireproof ball valve with a compound cooling disc bonnet, characterized in that the fireproof ball valve includes a valve body 1, a valve cover 33 is provided on the upper part of the valve body 1, and a valve cover is provided in the middle of the valve body. Spherical core body 21, both sides of spherical core body 21 are provided with valve seat 16, and the upper end of spherical core body 21 is connected with upper valve stem 36, and the lower end is connected with lower valve stem 10, and the upper section of upper valve stem 36 is sealed with valve cover 33. The graphite filler 11 in the letter matches, and passes through the bracket 32, and is connected with the actuator 31; the valve cover 33 is provided with a single large-diameter cooling disc 34, and the single-piece large-diameter cooling disc 34 is also provided with There are multi-circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com