Chute coal feeder for circulating fluidized bed boiler

A technology of circulating fluidized bed and coal feeder, which is applied to fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc. problems, to achieve stable and reliable coal supply, reduce moving parts, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

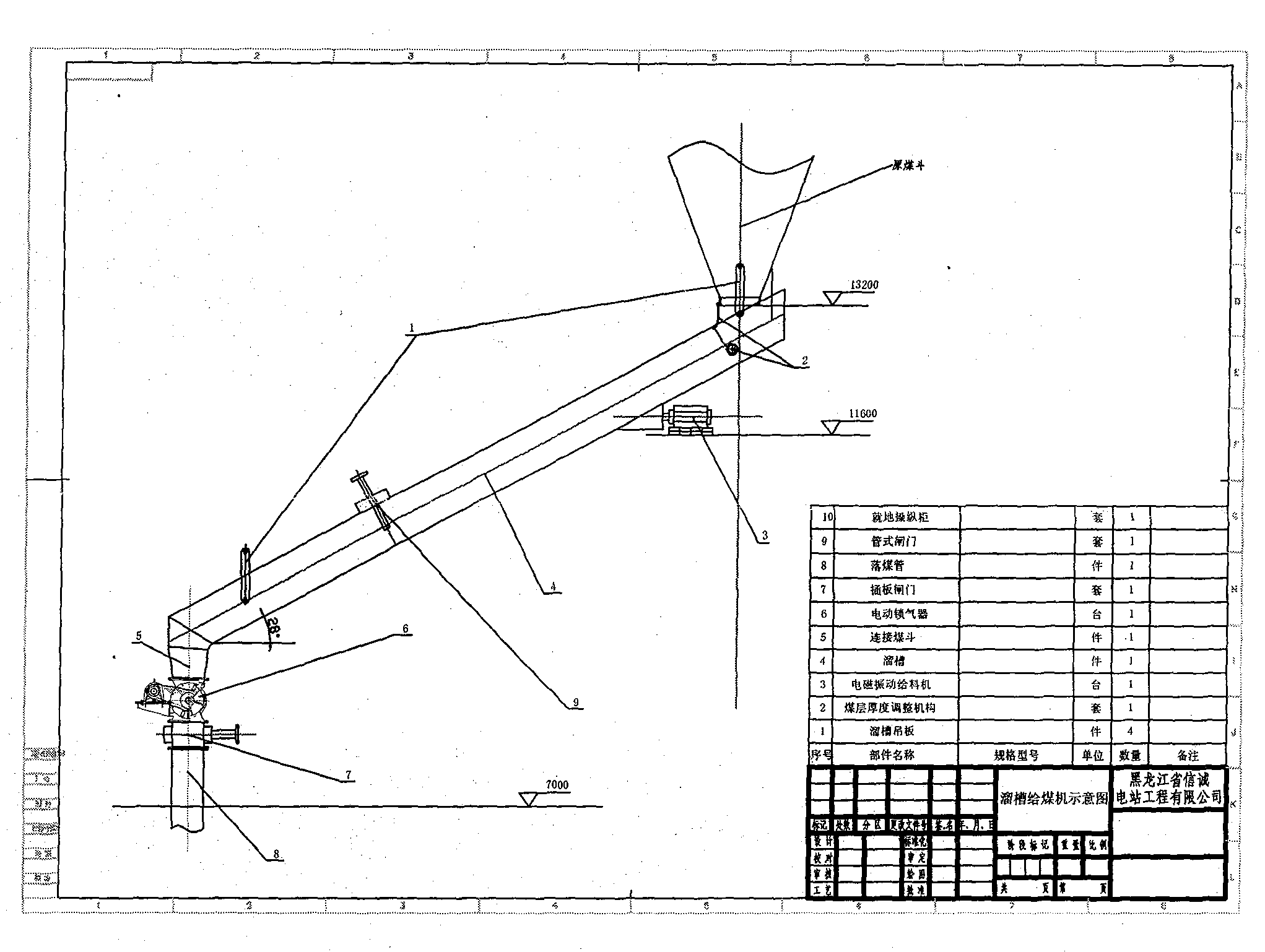

[0015] combine figure 1 Illustrate the embodiment, the circulating fluidized bed boiler chute coal feeder in this embodiment includes a chute hanging plate 1, a coal seam thickness (coal amount) adjustment mechanism 2, an electromagnetic vibrating feeder (device) 3, a chute 4, a connecting coal Bucket 5, electric air locker 6, plate gate 9, coal drop pipe 8, pipe gate 7, local operation (electrical control) cabinet 10, etc. The chute 4 is independently fixed by the chute hanging plate 1 with two degrees of freedom, and the fuel coal falls on the chute 4 from the coal hopper under the control of the coal seam thickness (coal amount) adjustment mechanism 2, and the cross section of the chute 4 is U Shaped, equipped with a protective layer of polymer materials, the horizontal angle of the chute 4 is 25° to 30°, and the chute 4 is equipped with an electromagnetic vibrating feeder (device) 3 to adjust the coal burning in the chute 4 by controlling the amplitude and frequency The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com