Quaternary body air heating furnace

A technology of hot blast stove and element body, which is applied in fluid heaters, air heaters, lighting and heating equipment, etc., and can solve problems such as heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

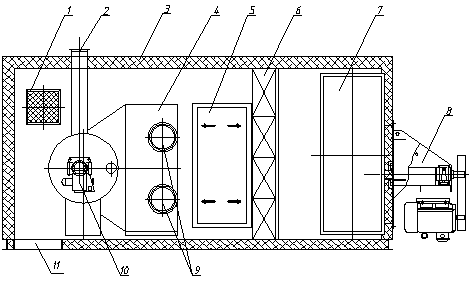

[0010] Quaternary body hot blast stove, the hot blast stove is equipped with a circulating air inlet 11, a circulating air outlet 7, a fresh air outlet 1, an exhaust gas outlet 2, a heat exchanger 4, a filter 6, a burner 10, and a smoke exhaust chimney 9 and the circulating fan 8, the circulating air inlet 11 is arranged at the lower part of the hot blast stove, the exhaust gas outlet 2 is arranged at the upper part of the hot blast stove, the burner 10 is arranged below the exhaust gas outlet 2, and the heat exchanger 4 Set in the middle of the hot blast stove, the filter 6 is set at the rear of the heat exchanger, the burner 10 is connected with a solenoid valve and a PLC intelligent controller, the hot blast stove is provided with an inspection door 5, the hot blast stove The shell is filled with insulation cotton 3, and the mixed air passes through the circulating air inlet 11 to exchange heat with the heat exchanger 4, and then passes through the action of the circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com