Novel fixed tube-sheet heat exchanger

A fixed tube-sheet type heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of leakage and corrosion resistance, poor effect, etc., to achieve full utilization of resources, The effect of reducing industrial use costs and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate description and understanding of the technical content of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

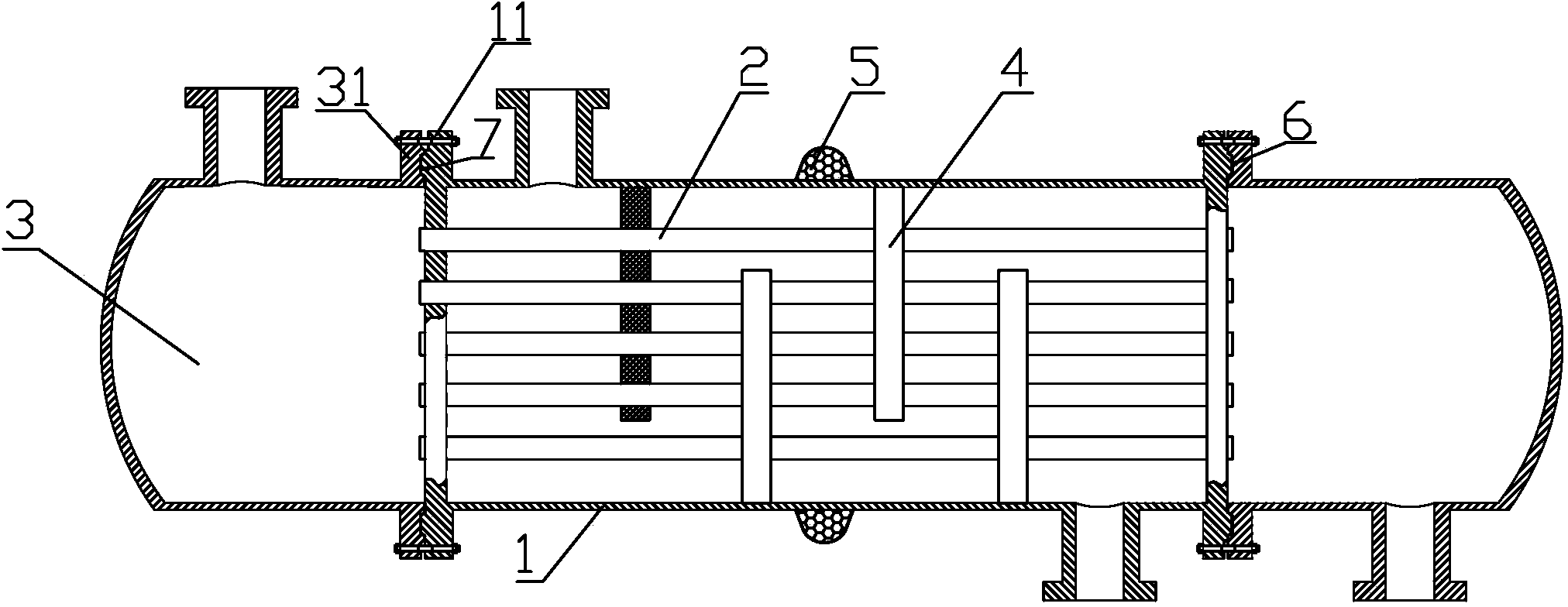

[0019] like figure 1 A new type of fixed tube-sheet heat exchanger is shown, which includes a shell 1 , heat transfer tubes 2 , tube boxes 3 , baffles 4 and expansion joints 5 . The tube box 3 is connected to the tube plate flange 11 welded on the tube plate at both ends of the shell 1 through the tube box flange 31; The trapezoidal groove 6 is provided with an annular sealing ring in the trapezoidal groove 6; corresponding to the trapezoidal groove 6, an annular trapezoidal boss 7 is provided on the tube plate flange 11.

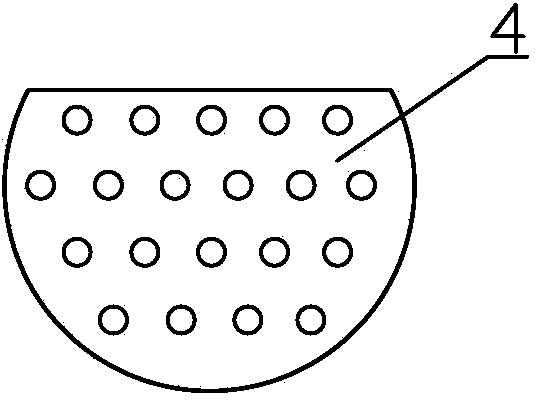

[0020] The baffle 4 is arranged in the housing 1, such as figure 2 As shown, the baffle 4 is a disc-shaped structure with a part cut off, and it is D-shaped and the radial length of its incomplete part is 1 / 4 to 1 / 3 of the inner diameter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com