Ship structure impact experiment boundary condition simulation device

A technology of structural impact and boundary conditions, applied in the direction of machine/structural component testing, measuring devices, impact testing, etc., can solve the problem of model similarity rate that has not been completely solved, it is difficult to measure the impact resistance of ship structures, and the test equipment is difficult to meet Requirements and other issues, to achieve the effect of convenient processing and installation, convenient quality control, and reduce the total quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

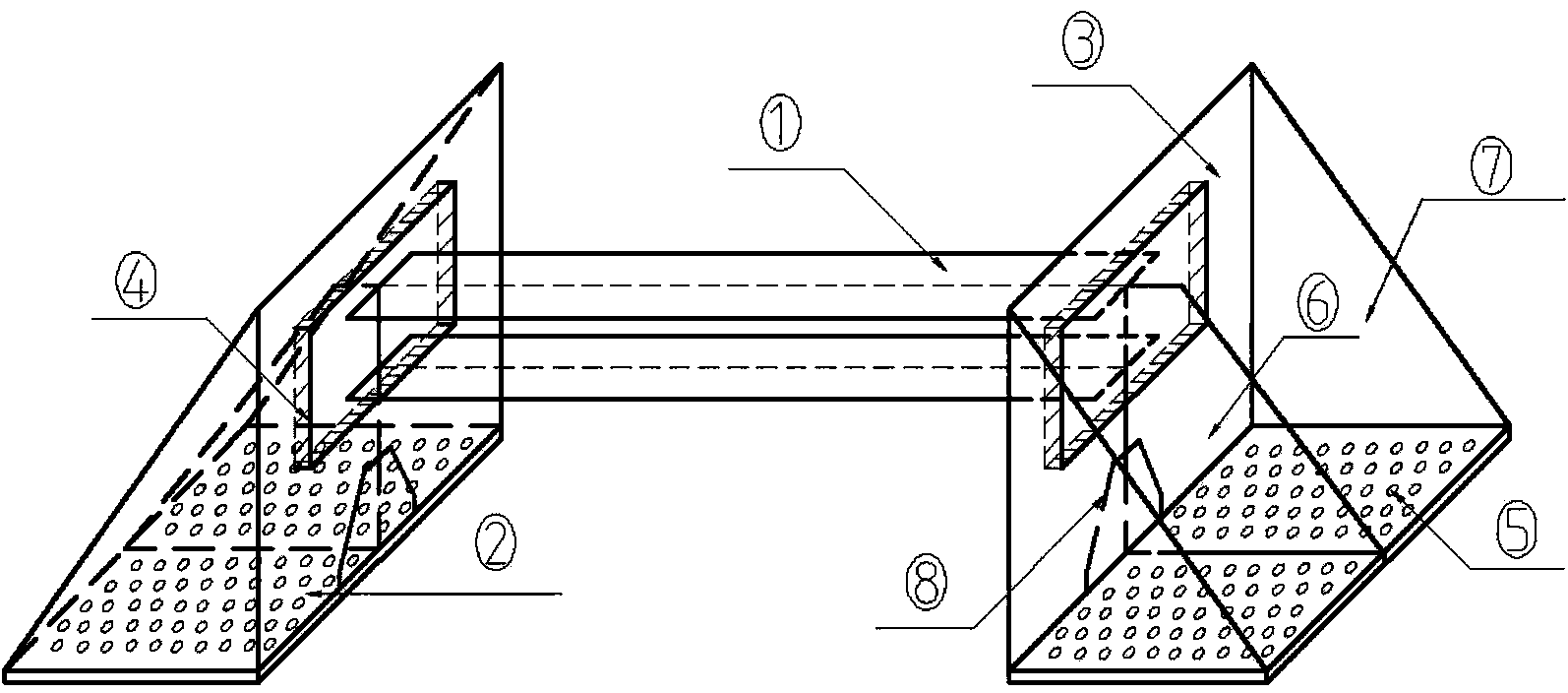

[0028] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

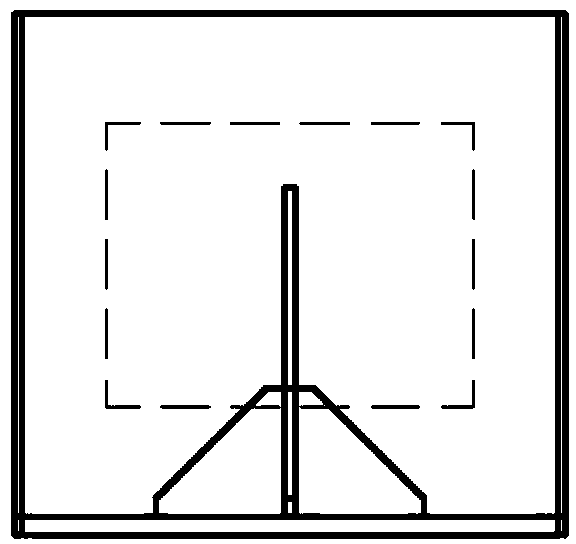

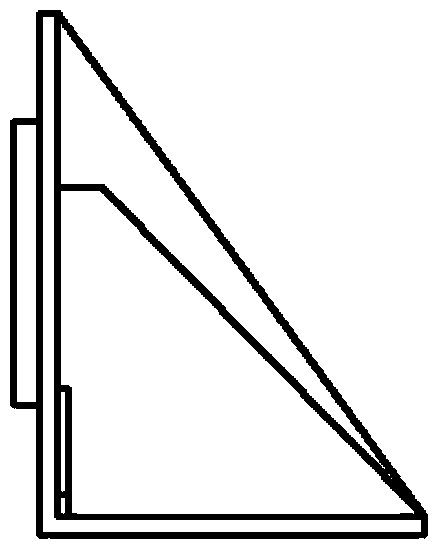

[0029] combine Figure 1-Figure 4 , the ship structure impact test boundary condition simulation device of the present invention comprises two horizontal plates 2 and two vertical plates 3, each horizontal plate and vertical plate are connected by a triangular support plate to form two right-angled "L" frame, each vertical The boundary rigid plate 4 is set in the center of the inner side of the plate, and the tooling for fixing the test components is set on the boundary rigid plate. The two ends of the test beam model 1 are respectively fixed between two right-angle "L"-shaped frames.

[0030] The horizontal plate is composed of an upper panel 9, a lower panel 10 and a composite cylinder 11. The upper panel and the lower panel are supported by the composite cylinder to form a composite structural plate. The grids are symmetrically distributed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com