Visual sample positioning operating system and method based on light spot detection

A sample positioning and operating system technology, applied in optics, measuring devices, optical components, etc., can solve the problems of operator inconvenience, poor adjustability and flexibility, lack of visual operation function of position sensing technology, etc., and achieve a simple optical path structure. , high portability, high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

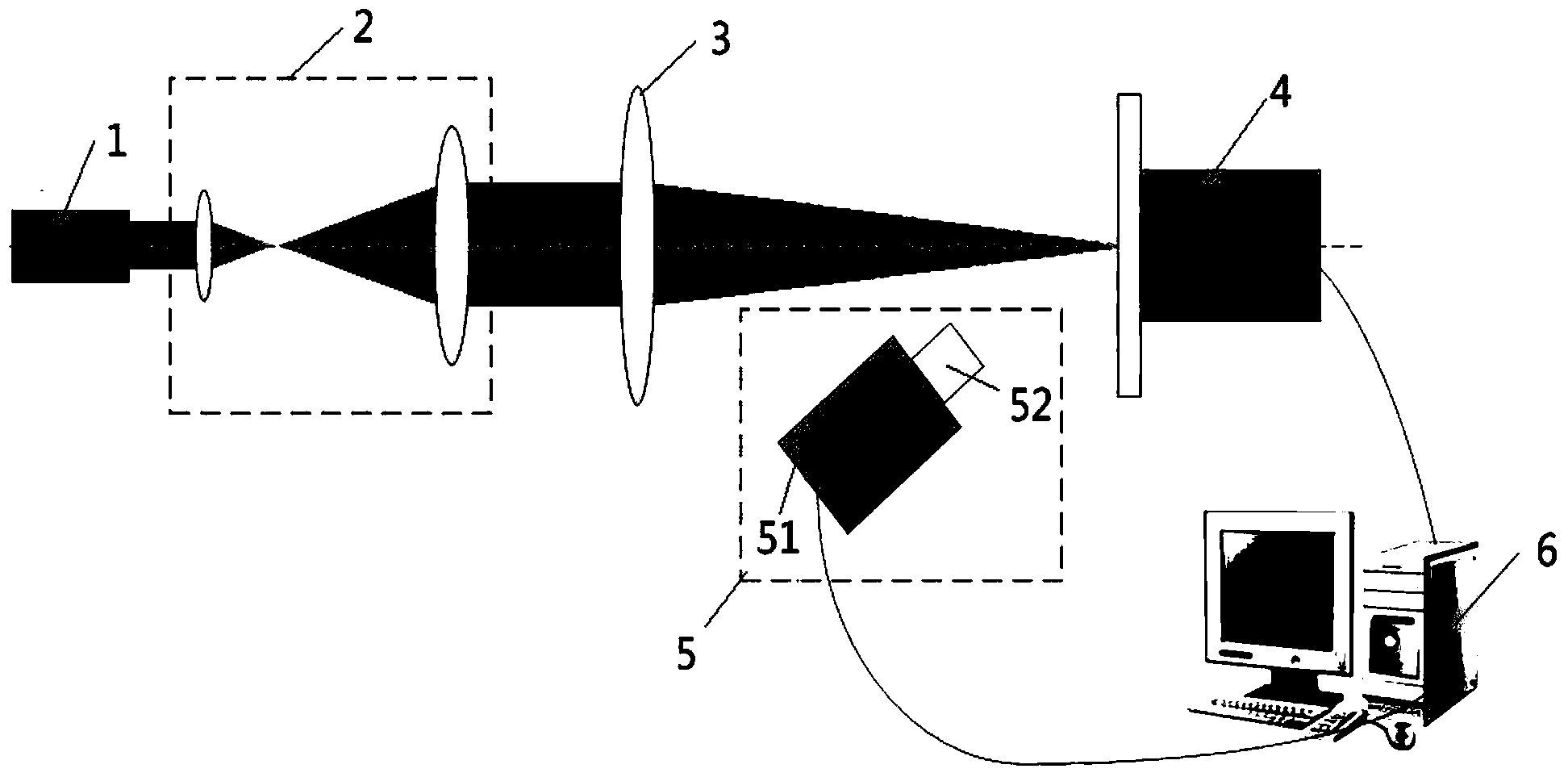

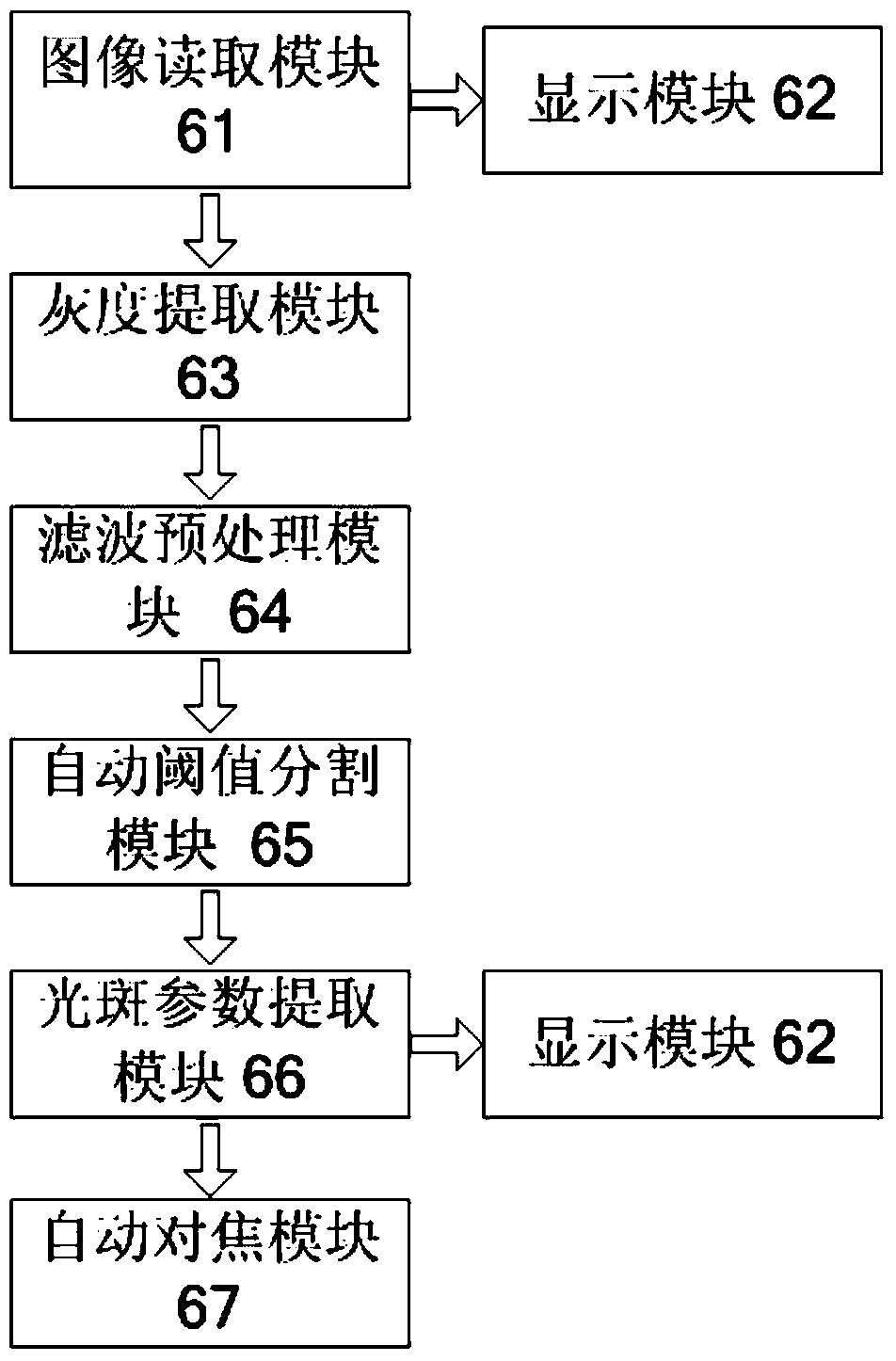

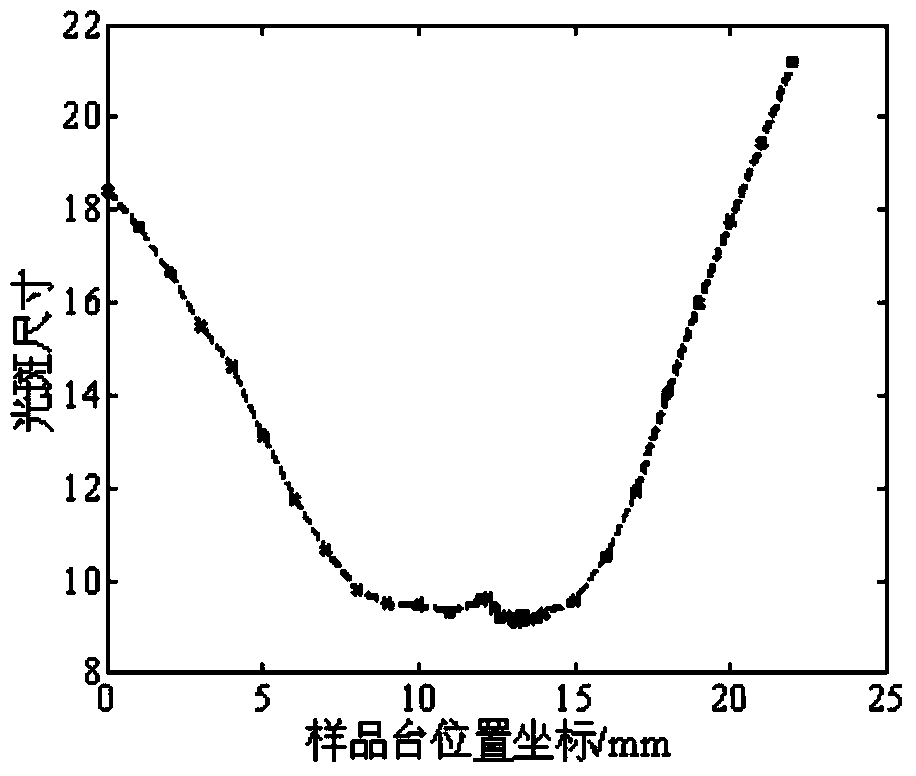

[0018] Such as figure 1 As shown, the visual sample positioning operating system based on spot detection of the present invention includes a visible light laser source 1, a collimating beam expanding unit 2, a beam focusing unit 3, an electronically controlled mobile sample stage 4, and a CCD image acquisition unit 5 and a computer6. The sample to be tested is loaded on the electronically controlled mobile sample stage 4 through an existing sample carrier, and the visible laser light source 1 is used as the marking light source, and the visible laser light emitted by it passes through the collimating beam expanding unit 2 and the beam focusing unit 3 in turn to form a cone. A marked light path; the tapered marked light path is emitted to the sample to be tested to form a marked spot, and the CCD image acquisition unit 5 collects the marked spot and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com