Photolithographic pattern for modeling and measurement method thereof

A graphics and measurement technology, which is applied in the direction of photo-plate making process of originals, optics, and patterned surfaces for photomechanical processing, can solve the problems of low quantity accuracy and unfavorable OPC model establishment, so as to improve efficiency and reduce Superposition of accumulated errors, effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

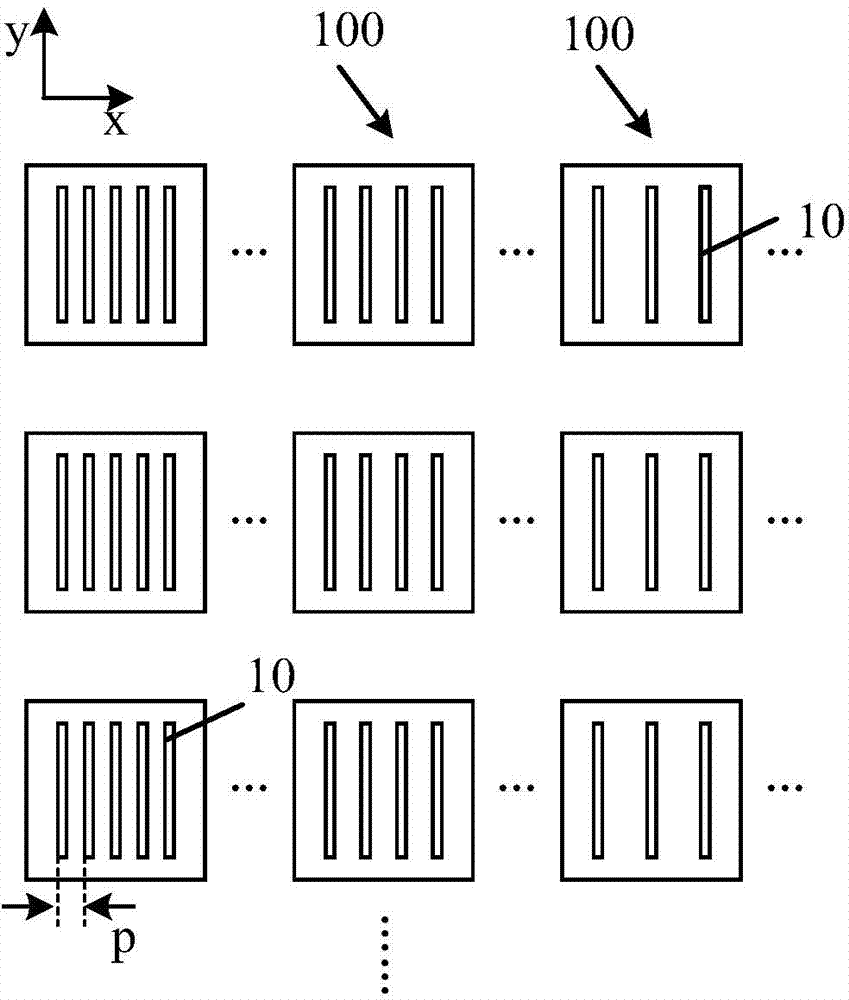

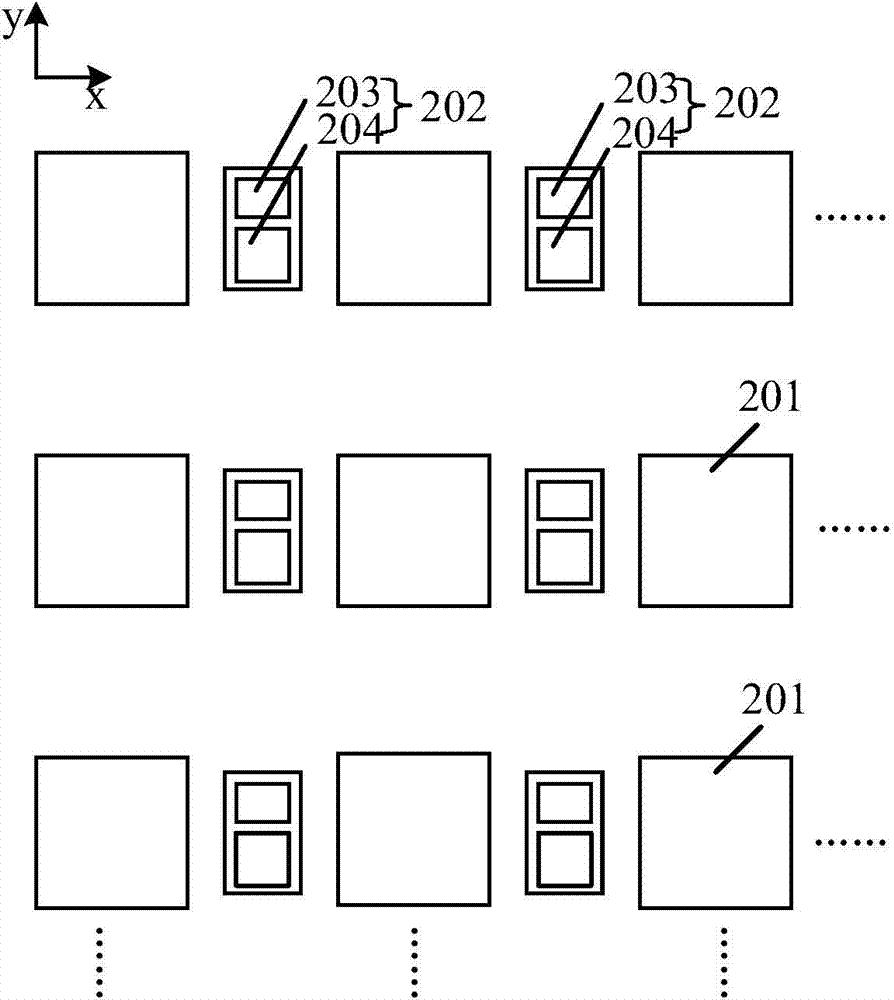

[0037] Please refer to figure 2 , the lithographic pattern for modeling includes: several reference patterns 201 distributed in rows and columns, and each reference pattern 201 includes a plurality of first linear patterns distributed at intervals; the auxiliary pattern between adjacent reference patterns 201 in each row Graphic 202, the auxiliary graphic 202 includes a position graphic 203 and a data graphic 204, the position graphic 203 is used to locate the reference position information of the adjacent reference graphic 201 and the reference position information of the data graphic 204, and the data graphic 204 uses Information about the row where the reference pattern 201 is located.

[0038] Specifically, the reference pattern 201 is usually formed on a photolithography mask. In the photolithography equipment, the reference pattern on the photomask is transferred to the photoresist layer through exposure and development processes, and then the photoresist layer is measu...

no. 2 example

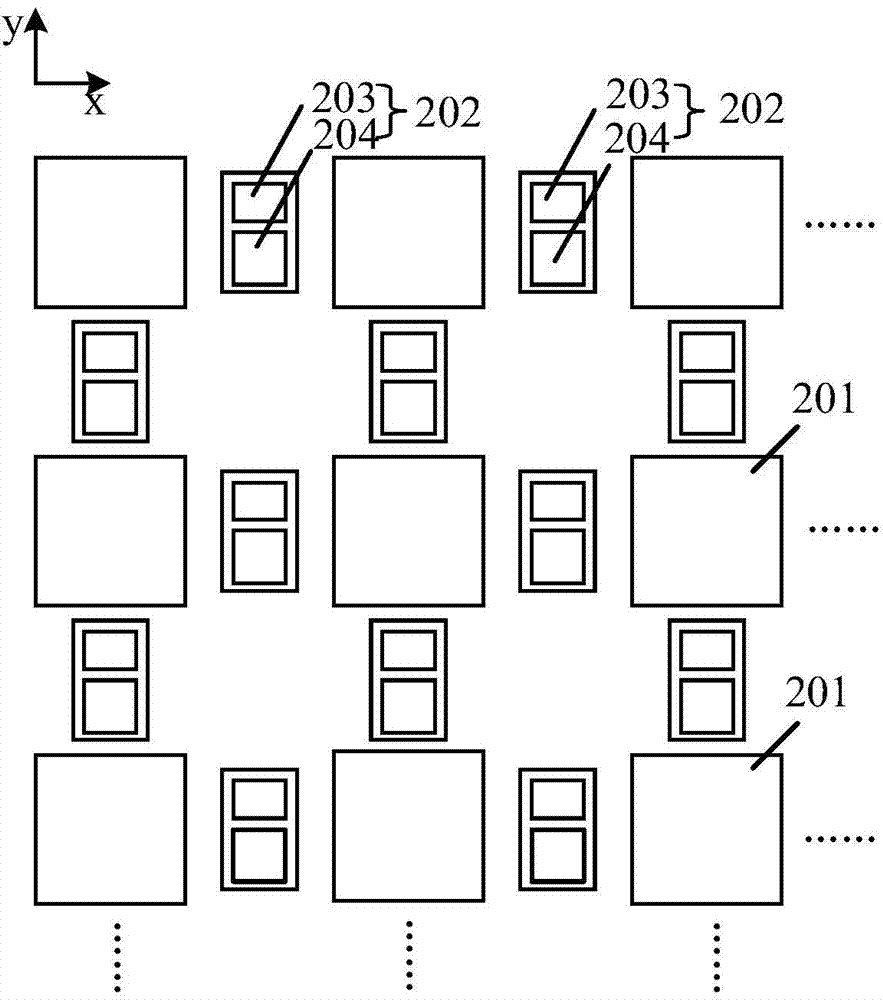

[0045] Please refer to image 3 , the lithographic pattern for modeling includes: several reference patterns 201 distributed in rows and columns, and each reference pattern 201 includes a plurality of first linear patterns distributed at intervals; between adjacent reference patterns 201 in each row and between Auxiliary graphics 202 between adjacent reference graphics 201 of each column, said auxiliary graphics 202 include position graphics 203 and data graphics 204, and said location graphics 203 are used to locate reference position information and data of adjacent reference graphics 201 The reference position information of the graphic 204, the data graphic 204 in each row is used for the information in the row where the positioning reference graphic 201 is located, and the data graphic 204 in each column is used for the information in the column where the positioning reference graphic 201 is located.

[0046] Compared with the first embodiment, in this embodiment, there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com