Toner for forming electrostatic image, development agent, image forming apparatus, and image forming method

An electrostatic image and toner technology, applied in the direction of developer, electric recording process using charge pattern, electric recording process using charge pattern, etc., can solve the problem of insufficient technology, caking resistance, and bad influence on image stability , Instable crystal structure and other problems, to achieve the effect of improving image hardness, excellent scratch resistance, and suppressing bad conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

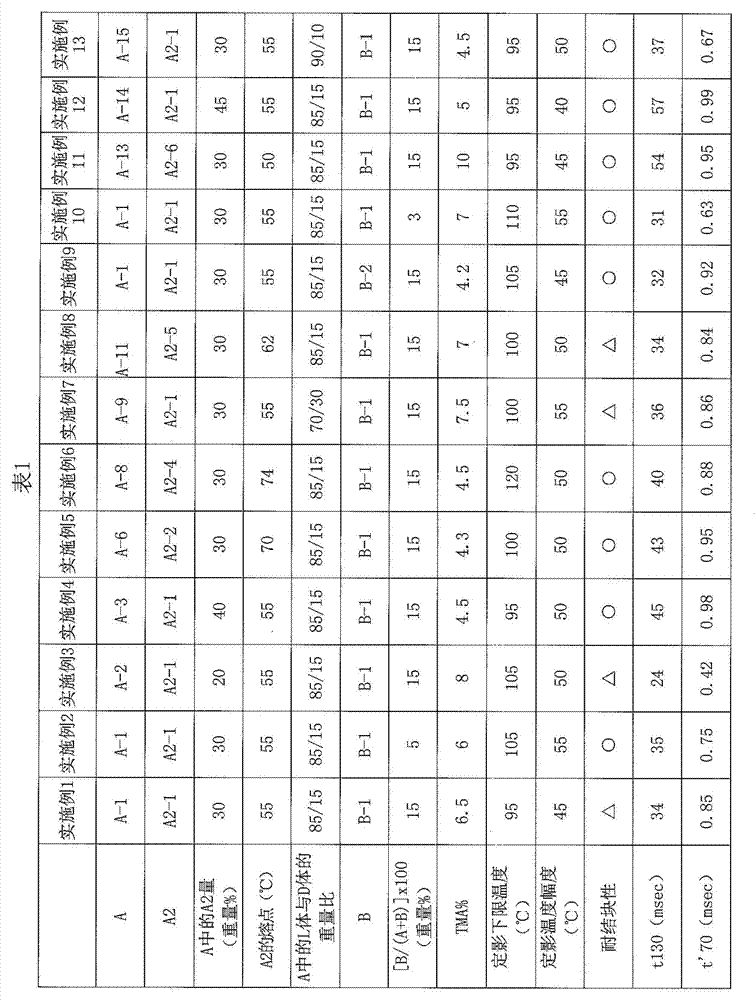

[0205] Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated more concretely, this invention is not limited to these Examples. "Parts" in the description are "parts by weight", and "%" with respect to the amount of materials is "% by weight".

Synthetic example 1

[0206] Synthesis Example 1: Synthesis of Block Copolymer A-1

[0207] Into a 500 mL four-necked flask, 212 g of L-lactide (lactide), 38 g of D-lactide (weight ratio, L body / D body = 85 / 15), and 107 g of the crystalline compound of Synthesis Example 2 described later were added. After polyester A2-1 was dried at 40°C for 5 hours, the internal temperature was gradually raised to 150°C, and after visually confirming that the reaction system was uniform, 50 mg of tin 2-ethylhexanoate was added to conduct a polymerization reaction. At this time, the temperature inside the system was controlled not to exceed 190°C. After 2 hours of reaction time, the system was cooled to 175° C., and the lactide was removed under the condition of 10 mmHg for 60 minutes to complete the polymerization reaction and obtain block copolymer A-1. The resin had a weight-average molecular weight Mw of 31,000 and a melting point of 51°C.

Synthetic example 2

[0208] Synthesis Example 2: Synthesis of Crystalline Polyester A2-1

[0209] Add 1,6-hexanediol and adipic acid at a ratio of OH / COOH=1.15 to a 5L four-necked flask equipped with a heated and dried nitrogen inlet tube, a dehydration tube, a stirrer, and a thermocouple, and 300 ppm tetraiso Titanium propoxide was reacted under normal pressure at 200 to 230° C. for 10 hours, and further reacted under reduced pressure of 10 mmHg or less for 5 hours to obtain crystalline polyester A2-1. The resin had a melting point of 55°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com