Automatic continuous water distribution system

A water distribution system, automatic technology, applied in the direction of electrical program control, program control in sequence/logic controllers, etc., can solve the problem of not taking into account the measurement of the water content of raw materials and finished products, that is, humidity, water resources cannot be fully utilized, waste, control methods Low production efficiency and other problems, to achieve the effect of eliminating rough control, low precision, high cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

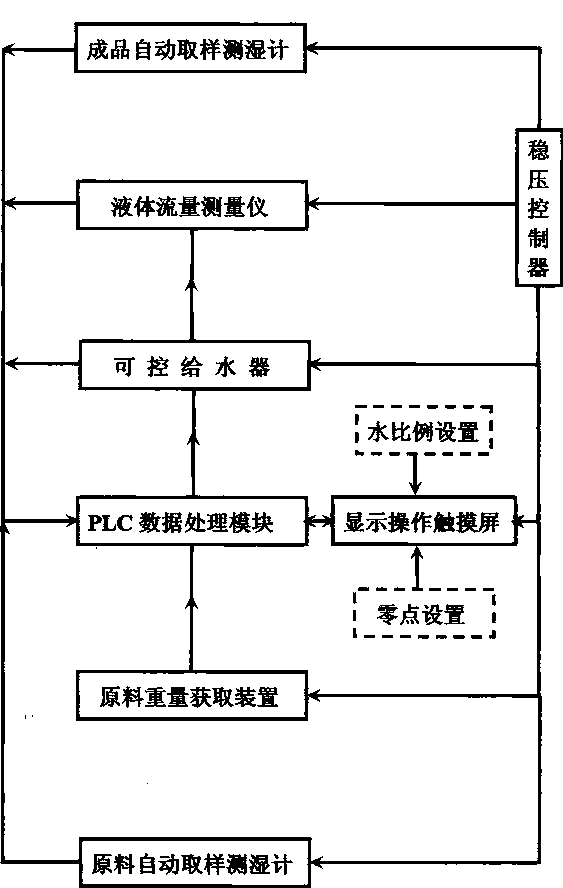

[0017] Such as figure 1 As shown, the automatic continuous water distribution system includes connected raw material automatic sampling hygrometer, raw material weight acquisition device, PLC data processing module, controllable water feeder, liquid flow measuring instrument, finished product automatic sampling hygrometer, voltage regulator controller, Displays the operation touch screen.

[0018] There are two parameter settings of water ratio setting and zero point setting on the touch screen.

[0019] The voltage regulator controller is connected separately with raw material automatic sampling hygrometer, raw material weight acquisition device, PLC data processing module, controllable water feeder, liquid flow measuring instrument, finished product automatic sampling hygrometer, and display operation touch screen to ensure the connection The operating voltage of each device is stable, avoiding the impact on the system effect caused by the change of the operating power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com