Insulated wire and coil using the same

A technology of insulating wires and insulating resins, which is used in insulated cables, insulators, insulated conductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] Hereinafter, embodiments of the insulated wire and the coil using the same according to the present invention will be specifically described with reference to the drawings.

[0034] (insulated wire)

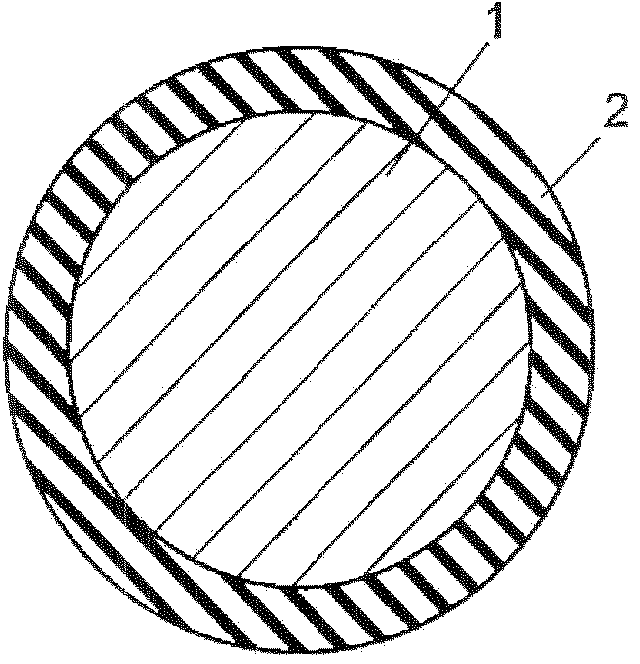

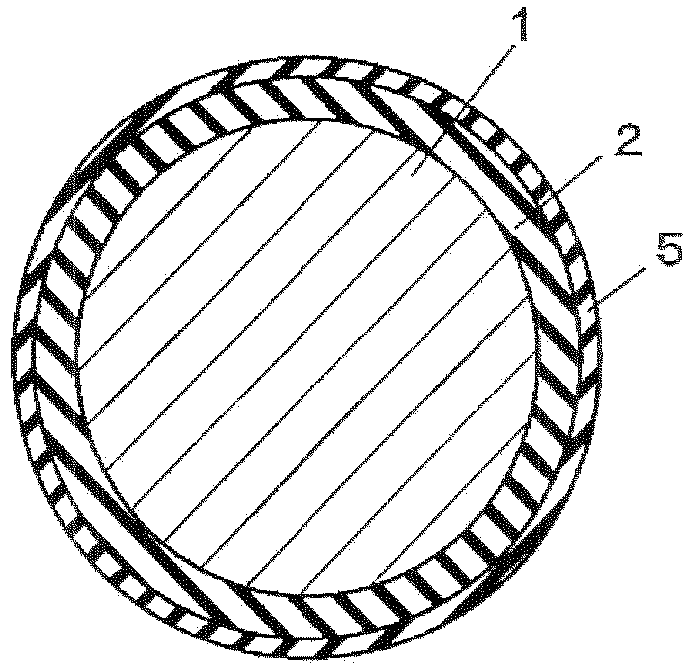

[0035] Figure 1A It is a sectional view showing the first embodiment of the insulated electric wire of the present invention. like Figure 1A As shown, the insulated electric wire of the present embodiment is configured to include: a conductor 1; and a first resin layer 2 formed on the outer periphery of the conductor 1 and containing inorganic fine particles and unreacted organometallics in an insulating resin.

[0036] In addition, the "unreacted state" refers to a state in which the organometallics are present in a state not reacted with the resin or the inorganic fine particles in the resin layer, and can react with the inorganic fine particles when the organometallics are exposed or the like.

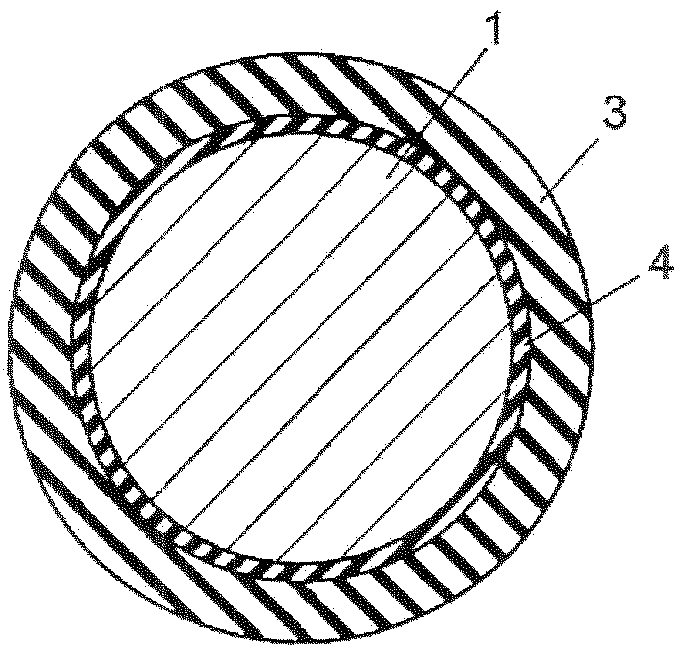

[0037] in addition, Figure 1B It is a cross-sectional view showing a s...

Embodiment 1)

[0068] Disperse organic silica sol (benzyl alcohol / naphtha-based mixed Dispersion medium, the average particle size of silica is 12nm), so that the silica component of the silicone sol becomes 20 parts by mass with respect to 100 parts by mass of the resin component of the coating material, and the organometallic (Matsumoto Seiki Co., Ltd.) is further mixed in an unreacted state Matsu moto Fine Chemical Co., Ltd. (manufactured by Matsu moto Fine Chemical Co., Ltd., trade name: ORGATIX TC-750), thus obtained coating for insulated wires (coating for partial discharge-resistant polyesterimide enameled wire), using the obtained The paint is applied on the copper conductor and fired to form the first resin layer to obtain an insulated wire with a one-layer structure (the film thickness of the insulating layer is 30 μm).

Embodiment 2~3)

[0070] In Example 1, the organosilicon sol as inorganic microparticles was dispersed so that the silicon dioxide component of the organosilicon sol became 5 parts by mass and 100 parts by mass respectively with respect to 100 parts by mass of the above-mentioned resin component. Example 1 was carried out in the same manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com