Silicon substrate air-impermeability sealing structure and manufacturing method thereof

A sealing structure and air-tight technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of poor structural strength, large pitch between through holes, and large package size, etc., to achieve reduced package size Size, simplify the production process, improve the effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

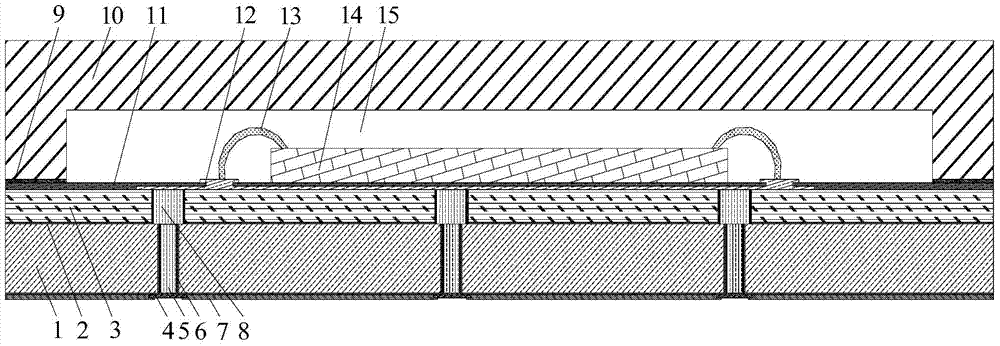

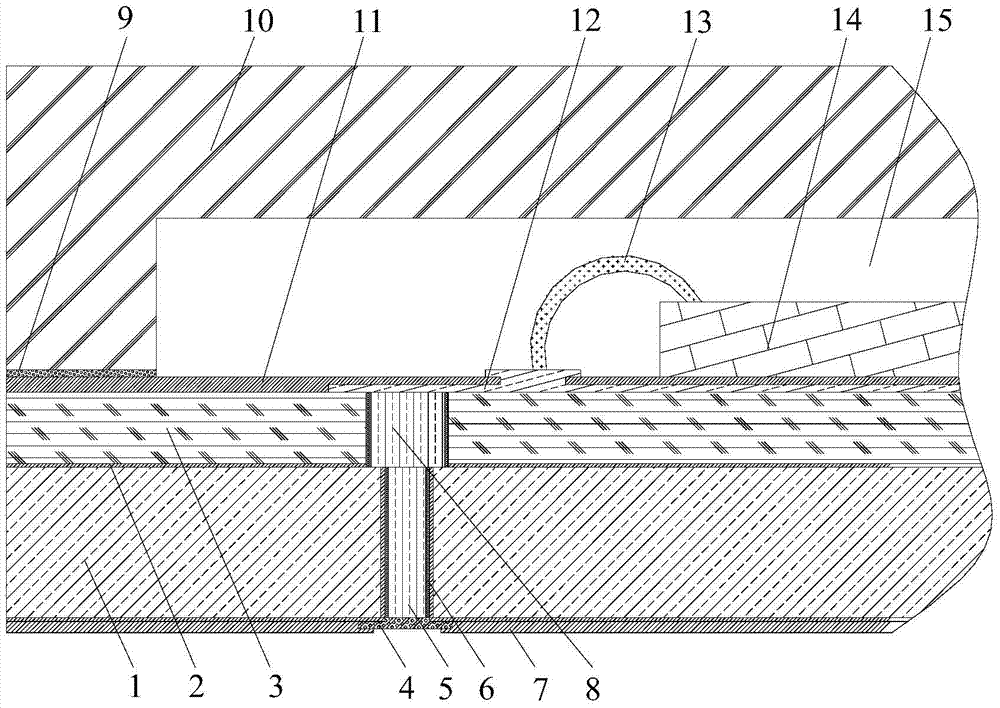

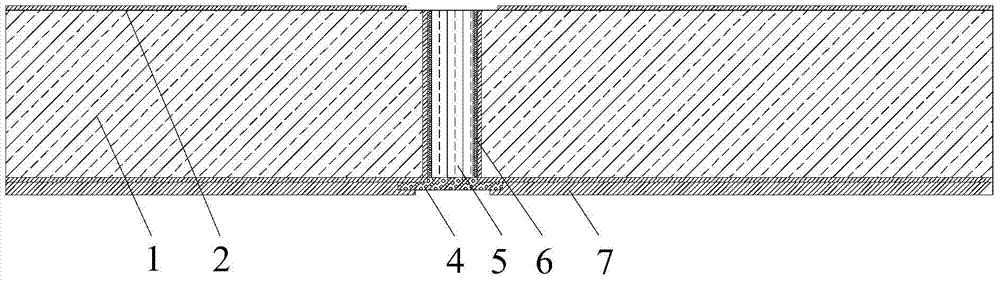

[0024] Such as figure 1 , as shown in 2, the silicon-based hermetic sealing structure of the present invention comprises a silicon substrate 1, a through hole is made on the silicon substrate 1, a first insulating layer 2 is deposited on the surface of the silicon substrate 1, and a seed layer is deposited on the inner wall of the through hole Metal 6, and then fill the first metal 5 in the through hole, the first metal wiring layer 4 is deposited on the back of the first metal 5; the front of the silicon substrate 1 is filled with a polymer dielectric layer 3, and the polymer dielectric layer 3 corresponds to Each position filled with the first metal 5 is made with an opening, and the opening is filled with the second metal 8; the upper surface of the polymer dielectric layer 3 is provided with a second metal wiring layer 12 and a second insulating layer 11, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com