Cooling power source control system for exciting power cabinets

A technology of excitation power cabinet and power control, which is applied in emergency power arrangement, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of unit safety and stability, hidden safety hazards, easy burning, and increased operation risks, etc., so as to eliminate the main and backup Power short-circuit, reduce the risk of downtime, shorten the effect of reconstruction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

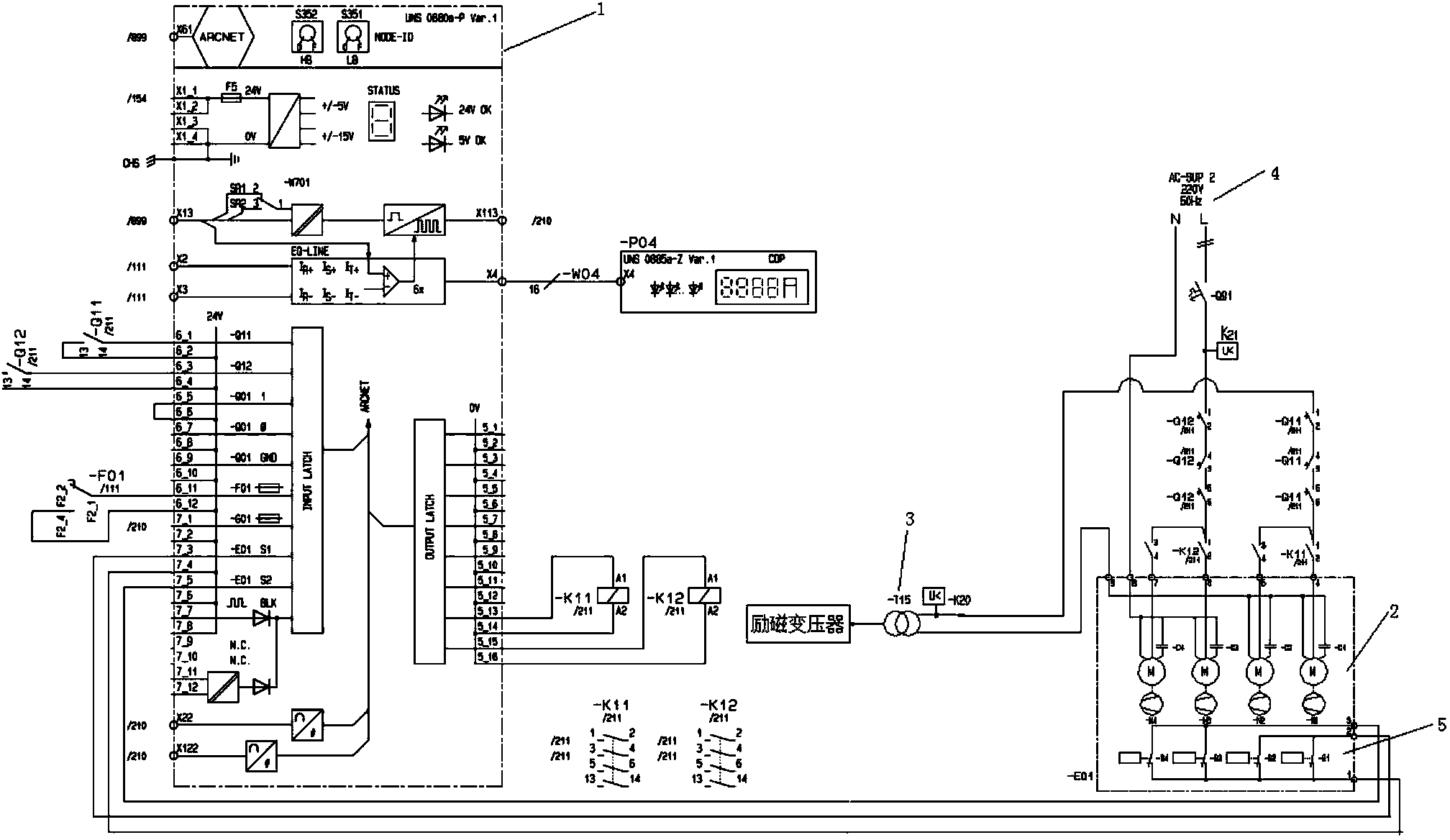

[0033] Such as figure 1 As shown, the cooling power supply control system of the excitation power cabinet of the present invention includes a plurality of power cabinets 2 and an excitation regulator control cabinet 1, each power cabinet 2 includes: a working power supply 3 for supplying power to the working fan, and is used to supply power to the standby fan The standby power supply 4 is used to monitor the power failure alarm circuit 5 of the working power supply 3 and the standby power supply 4; the working power supply 3 is connected to the working fan after passing through the voltage relay K20, the circuit breaker Q11 and the relay K11, and the standby power supply 4 is connected to the working fan through the voltage relay K21, The circuit breaker Q12 and the relay K12 are connected to the standby fan; the input terminal of the power failure alarm circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com