Method for producing float glass

A technology of float glass and its manufacturing method, which is applied in glass production, etc., can solve problems such as the inability to exist stably, the inability to reduce the surface tension of molten glass, etc., and achieve the effect of suppressing the increase of haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

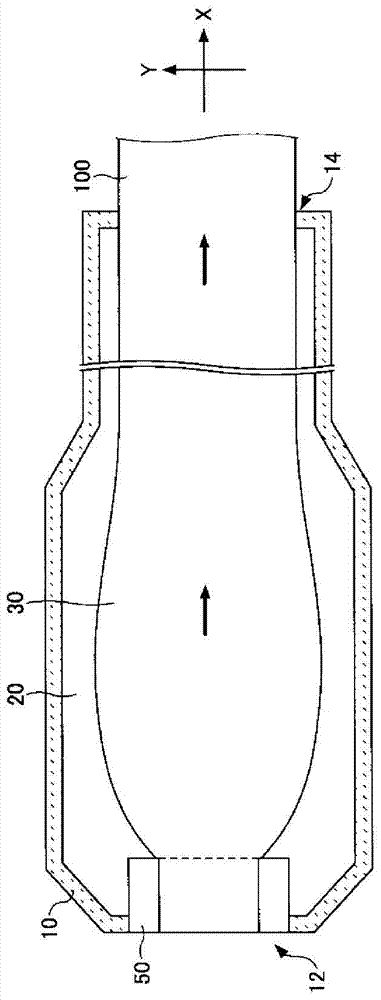

Image

Examples

Embodiment

[0073] Hereinafter, although an Example etc. demonstrate this invention concretely, this invention is not limited to these examples.

[0074] [Measuring method of various data]

[0075] (Sulfur concentration / chlorine concentration in the atmosphere in the tank)

[0076] The atmosphere in the tank is obtained by pumping through the quartz tube on the side wall of the tank. The suction speed is set to 2NL / min (=2×10 -3 N m 3 / min), the total suction volume is set to 100NL (=0.1Nm 3 ).

[0077] The length of the quartz tube was 120 cm, and the suction port of the quartz tube was arranged at a position 70 cm inside from the inner wall surface of the tank. The suction port of the quartz tube is arranged in the center of the width direction of the molten glass. The viscosity reaches 1×10 5 Lateral to the position of dPa·s. A part of the quartz tube was exposed outside the tank, and the quartz tube was cooled with dry ice from the outside.

[0078] The atmosphere in the tank ...

example 1~ example 7

[0100] In Examples 1 to 7, float glass was produced in the same manner except that the formulation of the glass raw materials was changed. Each glass raw material is changed by changing the sulfate (CaSO 4 ) or chloride (CaCl 2 ) to prepare the amount of addition.

[0101] Example 1, Example 4, and Example 7 are comparative examples. Example 2, Example 3, Example 5 and Example 6 are examples. In addition, the addition amount of the sulfate and chloride in Examples 1-6 was trace amount, and the addition amount of the sulfate and chloride in Example 7 was 0. Therefore, the float glass obtained in each example basically has the same composition, and the float glass obtained in Example 4 contains SiO when expressed in terms of mass percentage based on oxides. 2 : 59.5%, Al 2 o 3 : 17%, B 2 o 3 : 8%, MgO: 3.3%, CaO: 4%, SrO: 7.6%, BaO: 0.1%, ZrO 2 : 0.1%, and MgO+CaO+SrO+BaO: 15%, the balance is unavoidable impurities, and the total content of alkali metal oxides is 0.1% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com