Catalyst for low-temperature catalytic hydrogenation elimination of chlorophenol compounds in water and its preparation and application

A low-temperature catalysis and catalyst technology, which is applied in the preparation of chlorides, organic compounds, carbon-based compounds, etc., can solve the problems of difficult large-scale industrial application, complex palladium catalyst preparation, and complicated carrier preparation process. The route is convenient and practical, the price is low, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

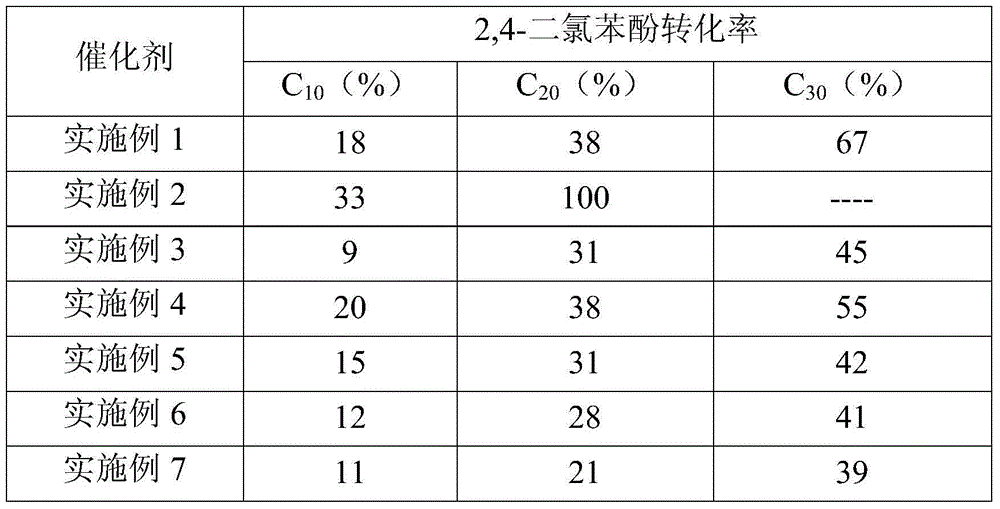

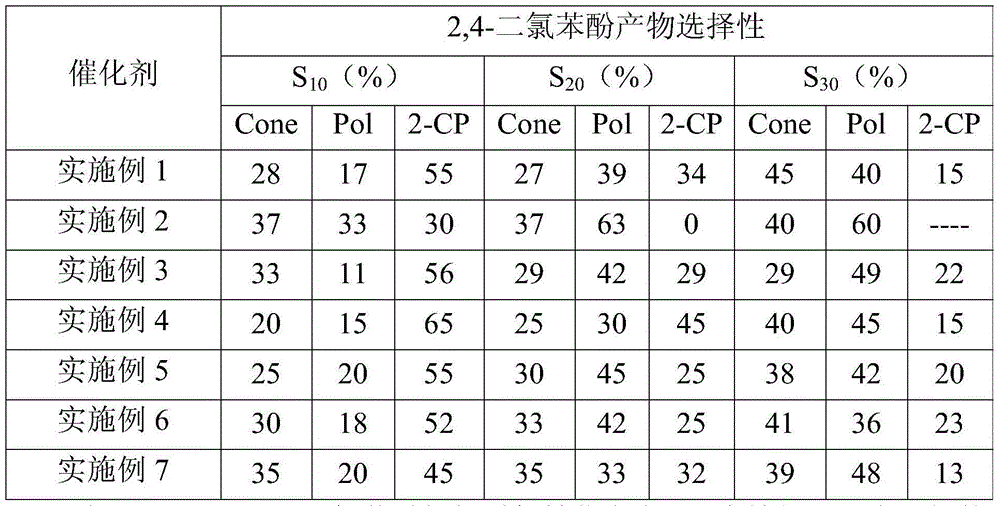

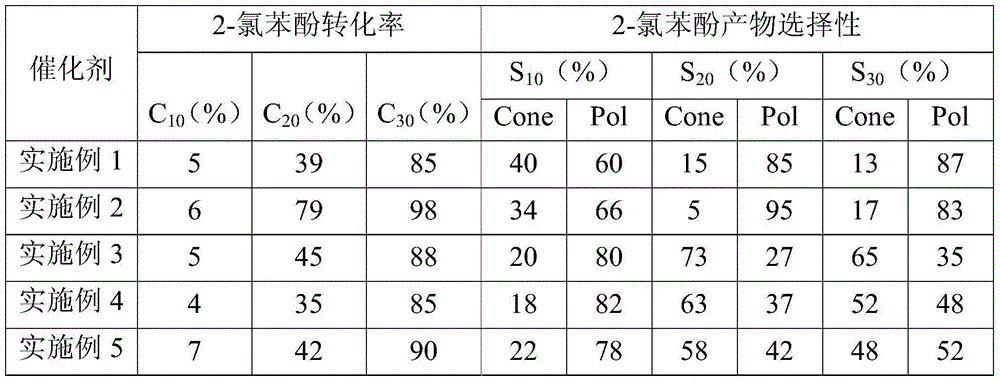

Examples

Embodiment 1

[0028] 3.53g of aluminum hydroxide was slowly added to 15g of water containing 6.3g of 85% phosphoric acid solution under vigorous stirring, and the mixture was added to 100g of water with stirring (which contains 3.35g of hexadecyl three Methyl ammonium bromide (CTAB), stir for 0.5h, then add 17.6g 25% tetramethylammonium hydroxide aqueous solution, stir for 72h, filter the mixture, wash with deionized water, dry at 70℃ overnight, and calcinate at 500℃ for 1h under nitrogen atmosphere , And then calcined at 500°C for 6h under air atmosphere to obtain phosphoric acid modified alumina carrier.

[0029] The commercially available palladium dichloride was prepared into a 10g / L aqueous solution, and 2ml of the solution was immersed in 1g of the phosphoric acid modified alumina powder prepared above, ultrasonicated for 10 minutes, and allowed to stand in the air overnight at room temperature and placed at 80°C Drying in an oven for 6 hours, dissolve 0.966g sodium borohydride in 50ml p...

Embodiment 2

[0031] 3.53g of aluminum hydroxide was slowly added to 15g of water containing 2.1g of 85% phosphoric acid solution under vigorous stirring, and the mixture was added to 100g of water with stirring (which contains 3.35g of hexadecyl three Methyl ammonium bromide (CTAB), stir for 0.5h, then add 17.6g 25% tetramethylammonium hydroxide aqueous solution, stir for 72h, filter the mixture, wash with deionized water, dry at 70℃ overnight, and calcinate at 500℃ for 1h under nitrogen atmosphere , And then calcined at 500°C for 6h under air atmosphere to obtain phosphoric acid modified alumina carrier.

[0032] The commercially available palladium dichloride was prepared into a 10g / L aqueous solution, and 2ml of the solution was immersed in 1g of the phosphoric acid modified alumina powder prepared above, ultrasonicated for 10 minutes, and allowed to stand in the air overnight at room temperature and placed at 80°C Drying in an oven for 6 hours, dissolve 0.966 g of sodium borohydride in 50...

Embodiment 3

[0034] 3.53g of aluminum hydroxide was slowly added to 15g of water containing 1.05g of 85% phosphoric acid solution under vigorous stirring, and the mixture was added to 100g of water with stirring (which contains 3.35g of hexadecyl three Methyl ammonium bromide (CTAB), stir for 0.5h, then add 17.6g 25% tetramethylammonium hydroxide aqueous solution, stir for 72h, filter the mixture, wash with deionized water, dry at 70℃ overnight, and calcinate at 500℃ for 1h under nitrogen atmosphere , And then calcined at 500°C for 6h under air atmosphere to obtain phosphoric acid modified alumina carrier.

[0035] The commercially available palladium dichloride was prepared into a 10g / L aqueous solution, and 2ml of this solution was immersed in 1g of the alumina powder prepared above, ultrasonicated for 10 minutes, and allowed to stand in the air overnight at room temperature, and placed in an oven at 80°C for drying 6h, dissolve 0.966g of sodium borohydride in 50ml of pH=12 sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com