Second main group element modified cobalt-aluminum catalyst as well as preparation method and application thereof

A technology of main group elements and catalysts, applied in the field of cobalt-aluminum catalysts modified by second main group elements and its preparation, can solve the problems of producing chloroform, carbon tetrachloride, etc., to promote catalyst activity, increase activity, inhibit The effect of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

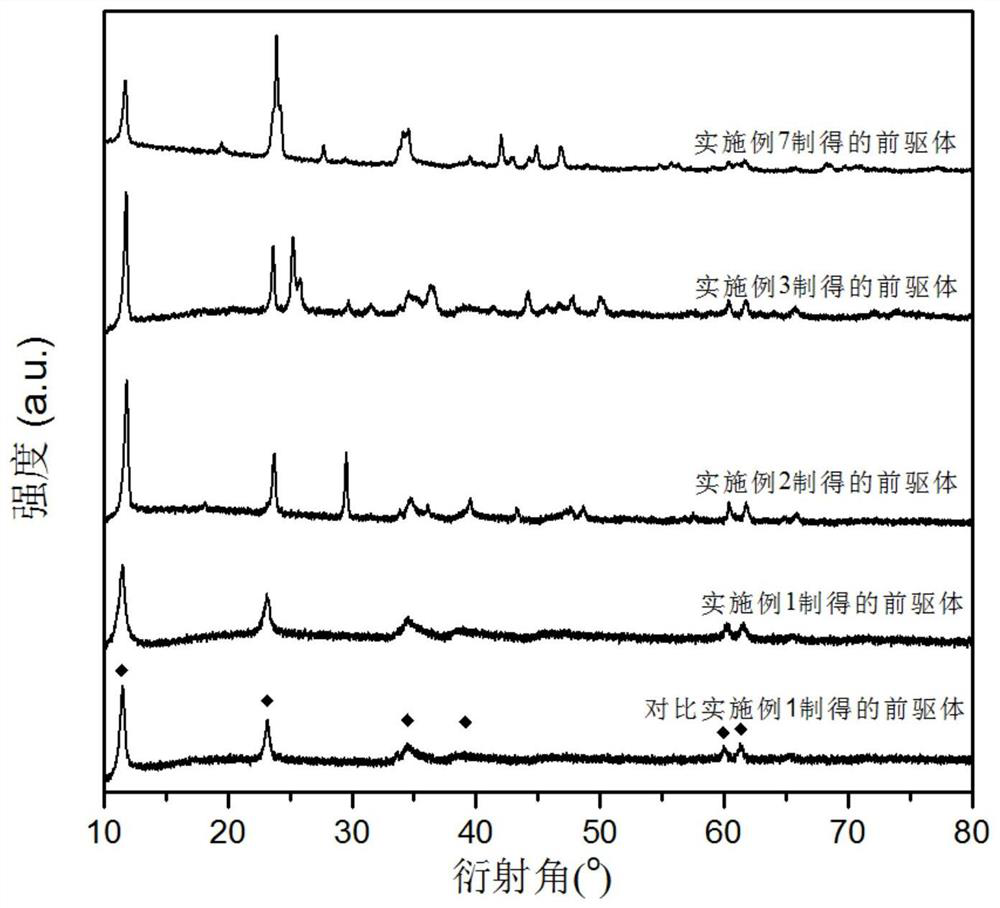

[0036] A cobalt-aluminum catalyst modified by the second main group element is prepared according to the following steps:

[0037] (1) Dissolve 8.73g of cobalt nitrate hexahydrate, 3.85g of magnesium nitrate, and 5.63g of aluminum nitrate in 50mL of deionized water, stir to form a salt solution, and dissolve 3.84g of sodium hydroxide and 3.18g of carbonic acid in 50mL of deionized water, Stir to form an alkaline solution, quickly add the alkaline solution to the salt solution and mix evenly to obtain a suspension;

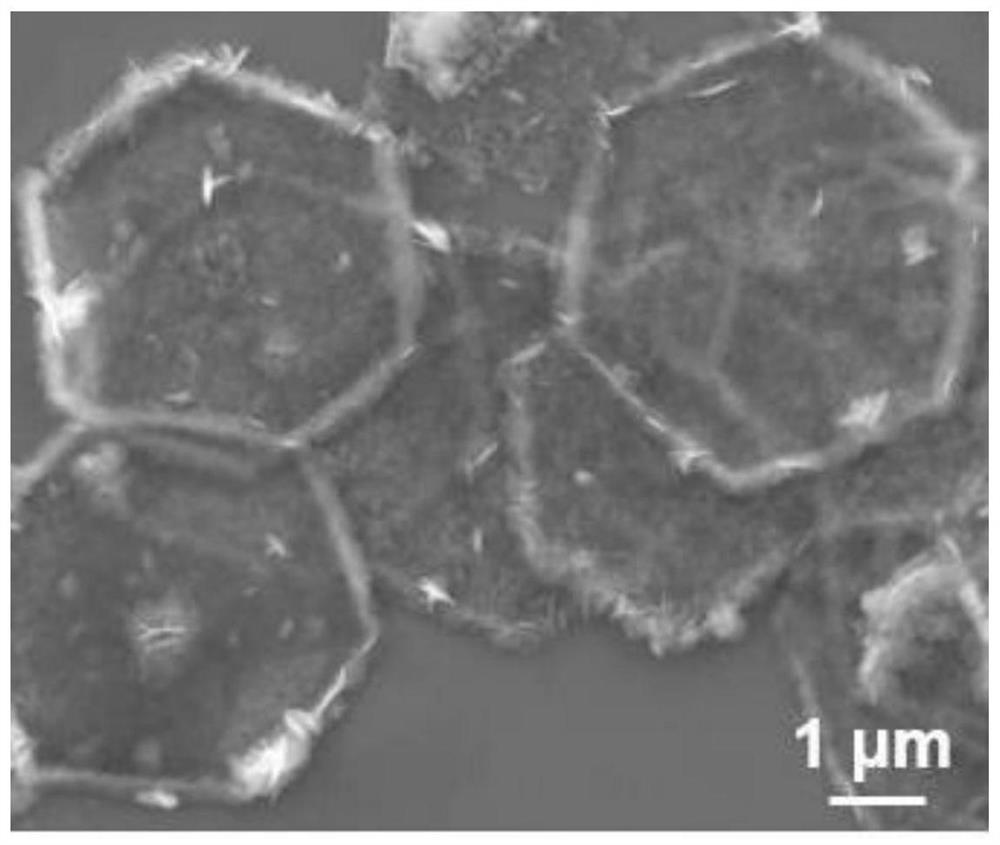

[0038] (2) Stirring and heating the suspension in an oil bath at 80°C for 24 hours, suctioning and washing after natural cooling, to obtain cobalt-aluminum hydrotalcite modified with the second main group element;

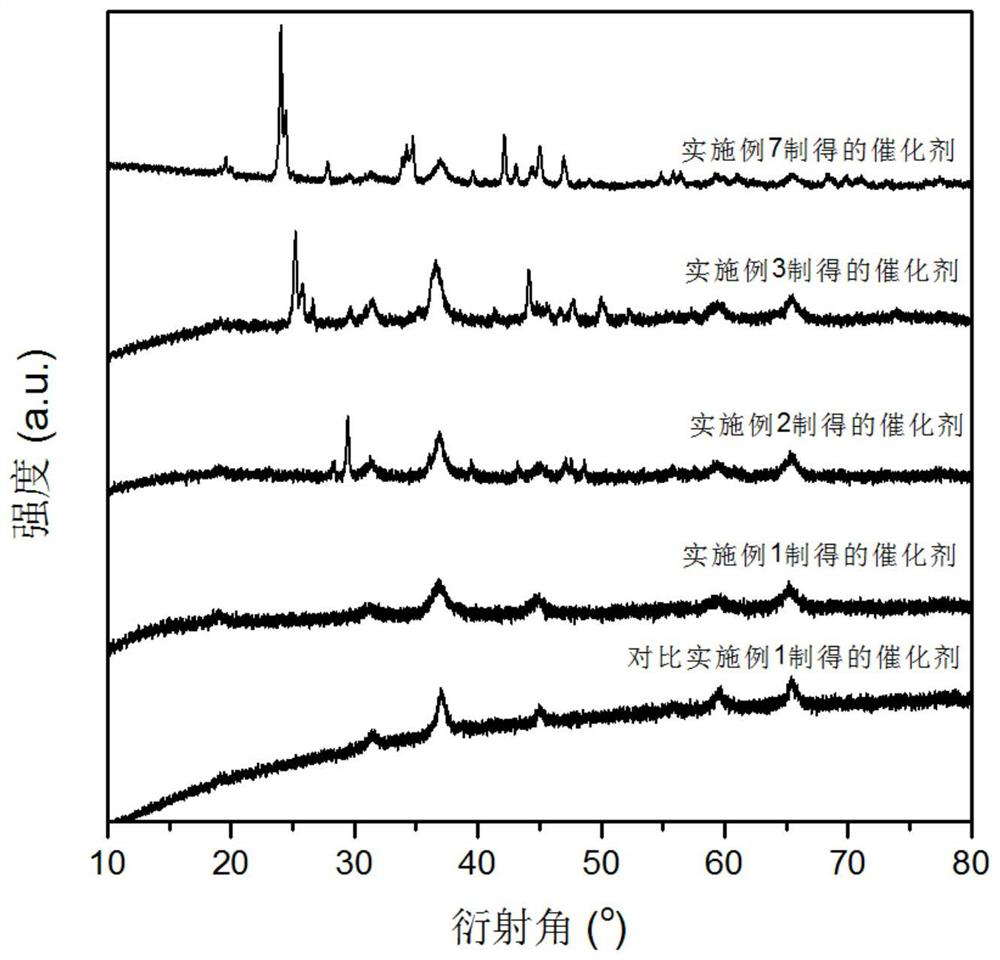

[0039] (3) Cobalt aluminum hydrotalcite was baked in an oven at 110°C for 24 hours, and then baked at 500°C for 4 hours to obtain Co 2 MgAlO x Catalyst, where x represents the indeterminate amount of O in the final catalyst, and finally exists in the ...

Embodiment 2

[0041] The main difference between this embodiment and embodiment 1 is that the second main group elements are different, as described below;

[0042] A cobalt-aluminum catalyst modified by the second main group element is prepared according to the following steps:

[0043] (1) Dissolve 8.73g of cobalt nitrate hexahydrate, 3.54g of calcium nitrate, and 5.63g of aluminum nitrate in 50mL of deionized water, stir to form a salt solution, and dissolve 3.84g of sodium hydroxide and 3.18g of carbonic acid in 50mL of deionized water, Stir to form an alkaline solution, quickly add the alkaline solution to the salt solution and mix evenly to obtain a suspension;

[0044] (2) Stirring and heating the suspension in an oil bath at 80°C for 24 hours, suctioning and washing after natural cooling, to obtain cobalt-aluminum hydrotalcite modified with the second main group element;

[0045](3) Cobalt aluminum hydrotalcite was baked in an oven at 110°C for 24 hours, and then baked at 500°C for...

Embodiment 3

[0047] The main difference between this embodiment and embodiment 1 is that the second main group elements are different, as described below;

[0048] A cobalt-aluminum catalyst modified by the second main group element is prepared according to the following steps:

[0049] (1) Dissolve 8.73g of cobalt nitrate hexahydrate, 3.17g of strontium nitrate, and 5.63g of aluminum nitrate in 50mL of deionized water, stir to form a salt solution, and dissolve 3.84g of sodium hydroxide and 3.18g of carbonic acid in 50mL of deionized water, Stir to form an alkaline solution, quickly add the alkaline solution to the salt solution and mix evenly to obtain a suspension;

[0050] (2) Stirring and heating the suspension in an oil bath at 80°C for 24 hours, suctioning and washing after natural cooling, to obtain cobalt-aluminum hydrotalcite modified with the second main group element;

[0051] (3) Cobalt aluminum hydrotalcite was baked in an oven at 110°C for 24 hours, and then baked at 500°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com